Novel eccentric powder grinding device

A new type of eccentric grinding technology, which is applied in the fields of cocoa, grain processing, food science, etc., can solve the problems of increasing equipment footprint, shortening the service life of grinding rollers, and blocking the material lifting device, so as to achieve high grinding efficiency and low cost. Inexpensive, fast grinding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

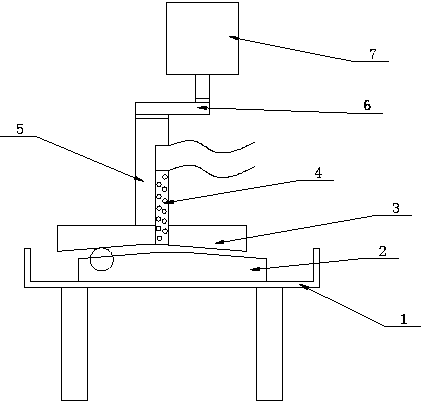

[0010] see Figure 1-2 , the specific embodiment adopts the following technical solutions: it includes a powder collecting bucket 1, a lower grinding disc 2, an upper grinding disc 3, a central transmission shaft 4, a hollow feeding tube 5, an eccentric disc 6, a driving motor 7, and wedge-shaped grinding teeth 8 , the middle of the upper end of the powder collecting bucket 1 is fixed with a lower grinding disc 2, the upper end of the lower grinding disc 2 is provided with an upper grinding disc 3, the upper end of the upper grinding disc 3 is fixed with a central transmission shaft 4, and one part of the central transmission shaft 4 The side is provided with a hollow feed pipe 5, which extends to the bottom of the upper grinding disc 3, and the upper end of the central drive shaft 4 is connected to the eccentric disc 6, and the eccentric disc 6 is connected to the driving motor 7.

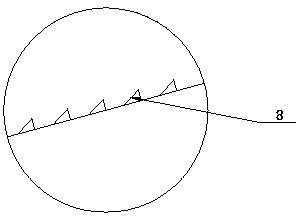

[0011] The surfaces of the lower grinding disc 2 and the upper grinding disc 3 are provided wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com