Valve body forming casting mold

A molding casting and mold technology, applied in the field of valve body molding casting molds, can solve the problems of core floating, high cost of resin sand, uneven wall thickness of valve body, etc., to reduce core floating, reduce solidification time, and reduce defects effect of influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

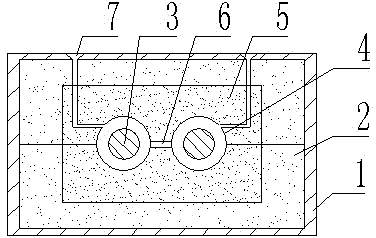

[0016] like figure 1 As shown, the valve sand casting mold includes a sand box 1, a sand mold, a core 3 and an anti-stick coating 4, and is characterized in that: the sand mold has a two-layer structure, and the contact part with the sand box is made of ordinary clay wet sand. Green sand layer 2, resin sand near the core is used as resin sand layer 5, the sand mold adopts a two-layer structure, which greatly saves the amount of resin sand used, and also ensures the function of resin sand. The core 3 adopts a double-core structure, the two cores are on the same horizontal line, and are connected to each other by the connecting rod 6, which effectively reduces the phenomenon of the core floating due to the pressure of the liquid metal and improves the quality of the casting. An anti-stick coating 4 is provided on the outer side of the resin ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com