Movable manual welding table for circuit board

A circuit board, movable technology, applied in printed circuits, welding equipment, auxiliary welding equipment, etc., can solve the problems of component displacement or falling, poor welding quality, easy to move, etc., to increase the utilization rate, Improve welding efficiency and improve aesthetics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

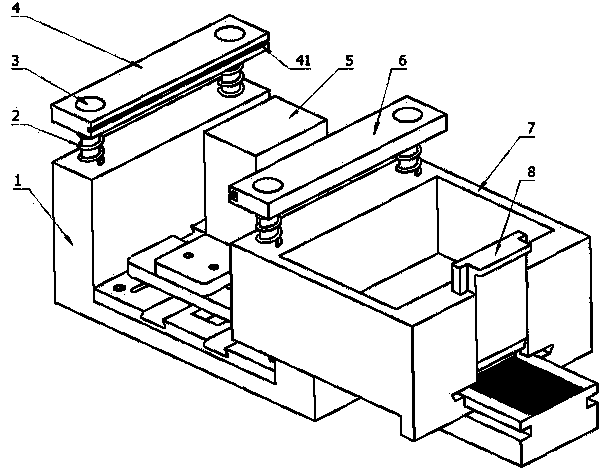

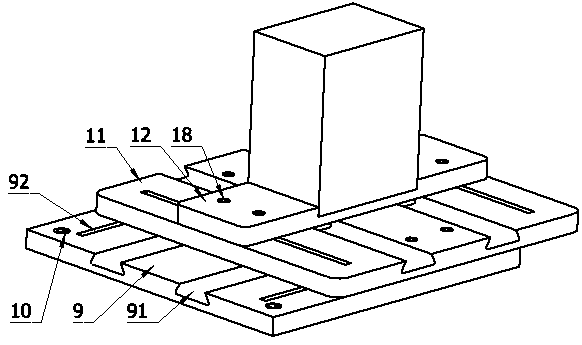

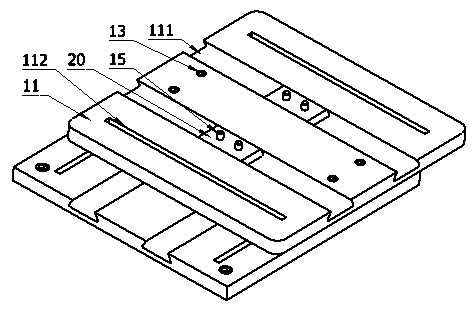

[0028] attached Figure 1-8It is a movable circuit board manual welding station according to the present invention, which includes a base guide rail, a cross slide module, and a movable clamp body module; one end of the base guide rail 1 is provided with a rectangular boss, and the other end of the base guide rail 1 is provided with a I-shaped guide rail 104; said rectangular boss is provided with two threaded holes 101 arranged at intervals, and each threaded hole 101 is provided with a guide rod 3; each guide rod 3 is sleeved with a large spring 2; The threaded end of the guide rod 3 passes through the stepped hole on the upper surface of the jaw 4 and is threadedly connected with the threaded hole 101, and the other end of the guide rod 3 is provided with a circular boss, and the circular boss can be Placed in the large hole of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com