Elevator Ropes

A technology of cables and elevators, which is applied in the field of improved structure of cables for active ropes, can solve the problems of a lot of labor, time and cost for cable maintenance and inspection, the inability to determine the exact position of wire breakage, labor-intensive and time-consuming manufacturing, etc., to achieve Effects of suppressing mountain breakage, improving service life, and increasing filling rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Hereinafter, an elevator rope according to an embodiment of the present invention will be described with reference to the drawings. In addition, the embodiment described below is an example for demonstrating this invention, and this invention is not limited to the said embodiment. Therefore, the present invention can be carried out in various forms within the scope not departing from the gist thereof.

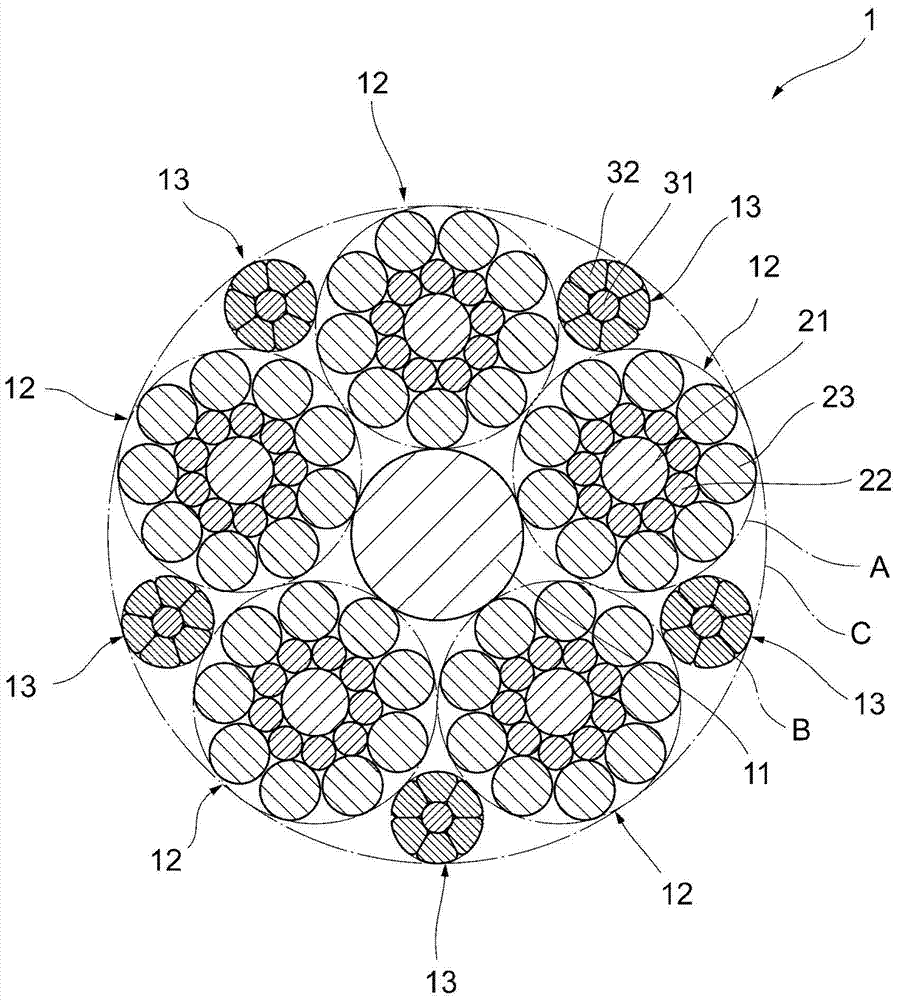

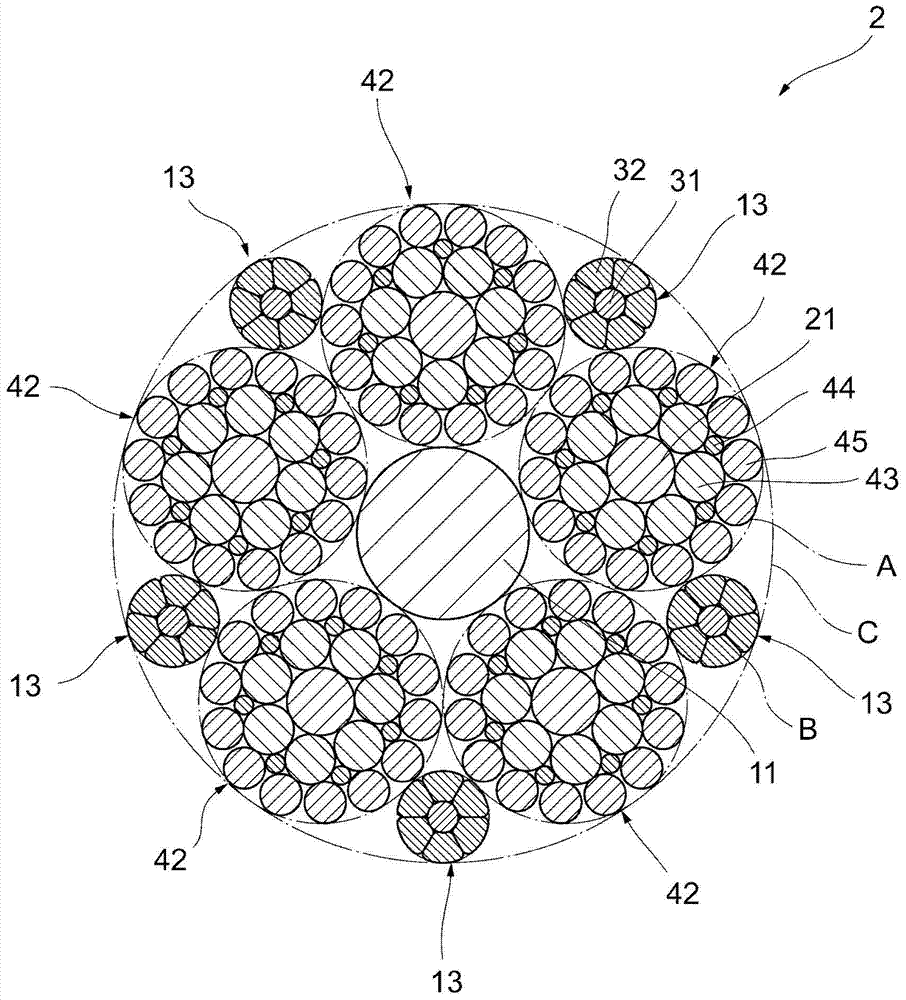

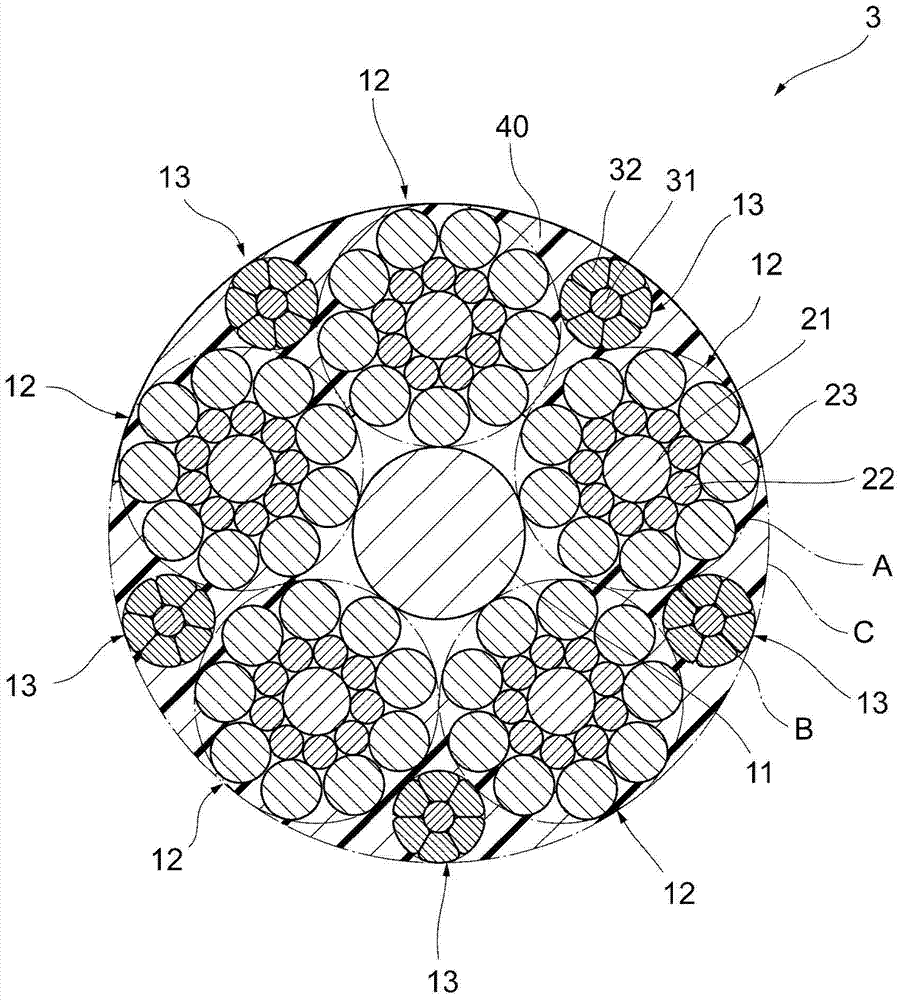

[0033] figure 1 It is a cross-sectional view of the elevator rope according to the first embodiment of the present invention. exist figure 1 In , the thicknesses, dimensions and enlargement / reduction ratios of various components do not correspond to actual ones for convenience of description.

[0034] like figure 1 As shown, the elevator rope 1 according to the first embodiment has a core 11 constituting the center of the rope 1, five side strands 12 and five auxiliary strands 13 arranged along the outer periphery of the core 11, five The auxiliary strands 13 are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com