Giant-pen-shaped oxygen lance

A giant oxygen lance and oxygen tube technology, which is applied in the manufacture of converters and other directions, can solve the problems of the oxygen lance being difficult to remove slag, low in use efficiency, and not wear-resistant, so as to achieve low maintenance and maintenance costs, high use efficiency, and installation. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Below in conjunction with accompanying drawing and example the present invention will be further described:

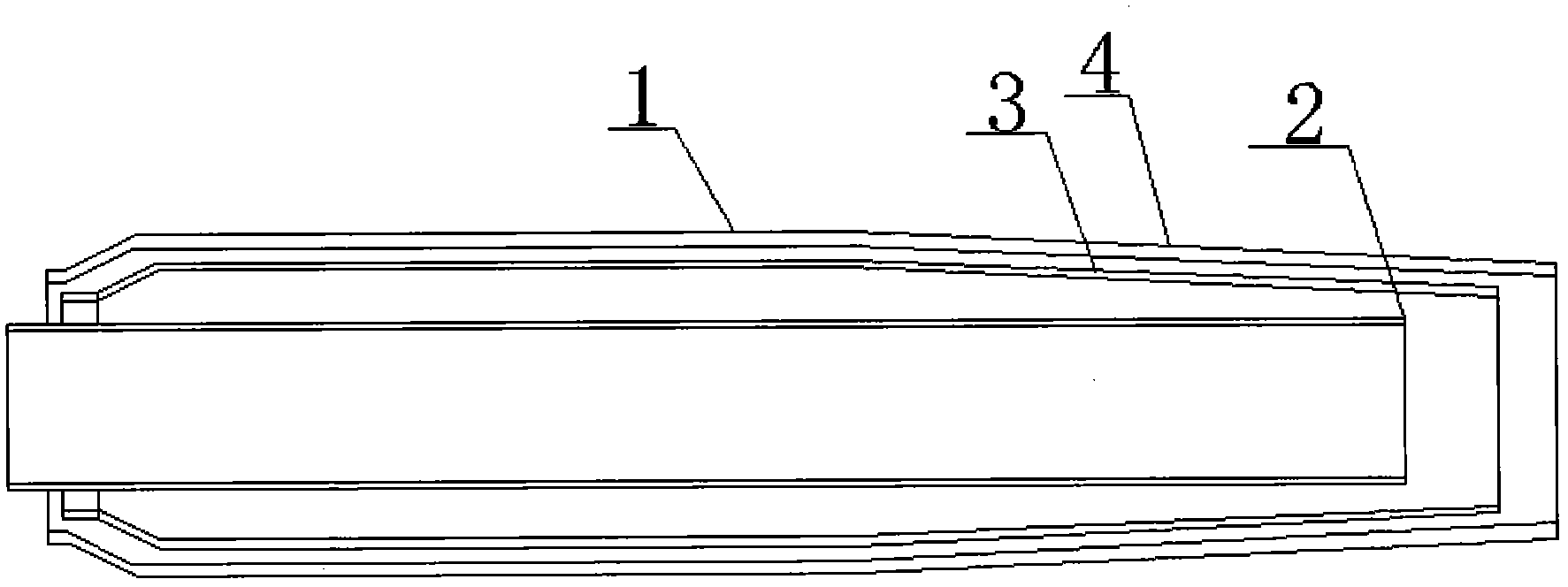

[0012] Such as figure 1 As shown, a giant pen oxygen lance is characterized in that it includes: an outer tube straight section 1, an oxygen tube 2, a water tube 3 and an outer tube composite cone section 4, and the outer tube is composed of an outer tube straight section 1 and an outer tube Cone section 4, the straight section of the outer tube and the composite cone section of the outer tube are seamlessly connected and integrally formed, the straight section of the outer tube is forged from a thick-walled seamless tube, the composite cone section of the outer tube is made of composite materials, and the inner side is made of steel Forged seamless pipe, the outer surface is an alloy layer, the water pipe 3 and the oxygen pipe 2 are fixed in the cavity formed by the straight section of the outer pipe 1 and the composite cone section of the outer pipe 4, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com