Environmentally friendly steam energy hot water production process

A production process and environment-friendly technology, applied in the field of environment-friendly steam energy hot water production process, to achieve the effect of maximizing conversion efficiency, saving consumption, and avoiding air pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

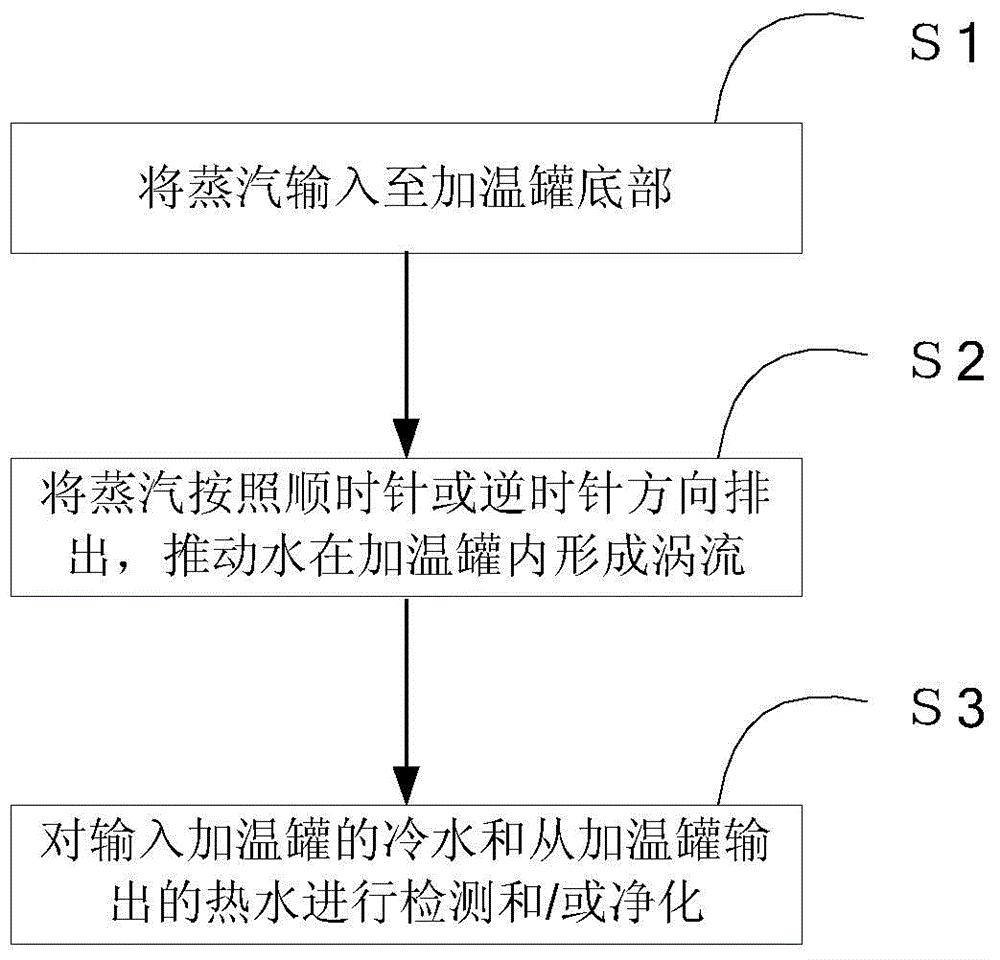

[0025] figure 1 A flow chart of the steps of the hot water conversion production process is shown.

[0026] The environment-friendly steam energy hot water conversion production process includes: pushing water to form a vortex in the heating tank 1 through the injected steam.

[0027] Such as figure 1 As shown, the specific steps of the production process include:

[0028] In step S1, steam is input to the bottom of the heating tank 1 .

[0029] In step S2, the steam is ejected in a clockwise or counterclockwise direction, and the water is driven to form a vortex that turns accordingly in the heating tank 1 .

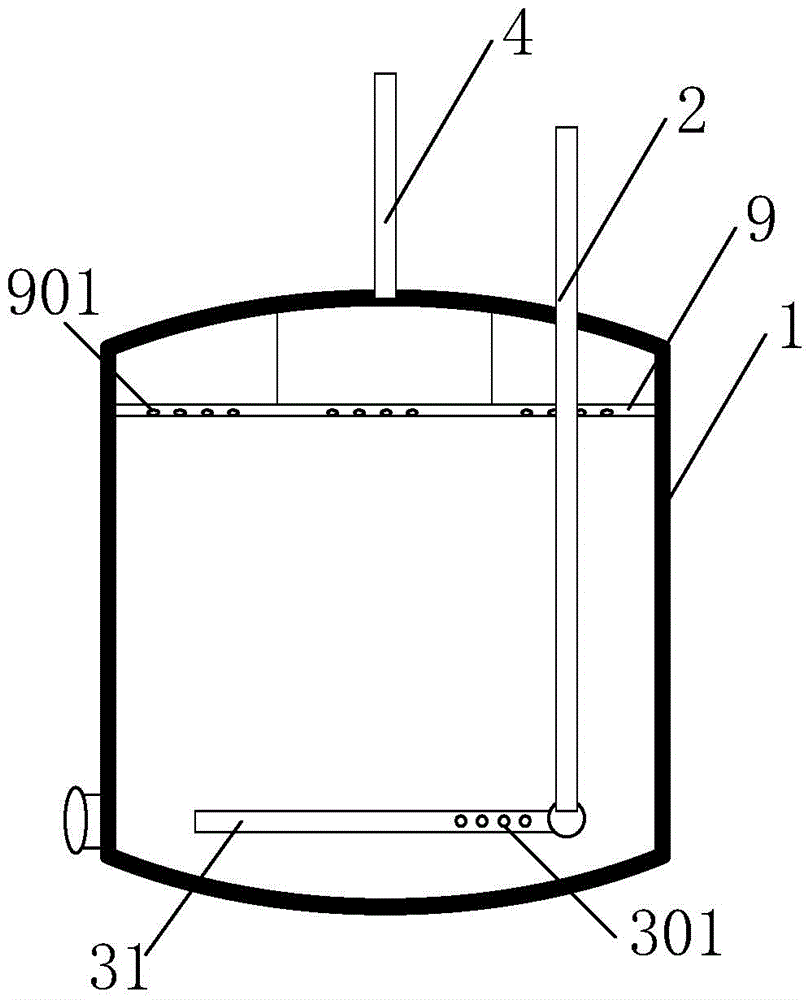

[0030] figure 2 A schematic structural diagram of a heating tank in an environment-friendly steam energy hot water conversion system is shown.

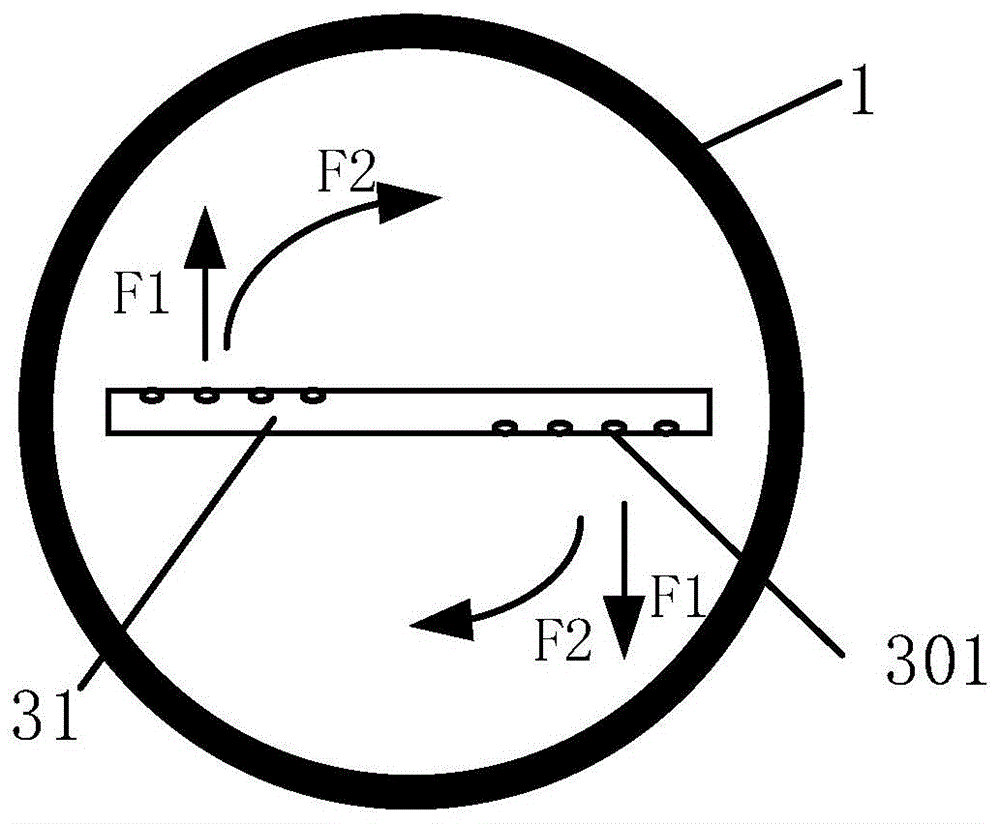

[0031] image 3 A schematic diagram showing the structure of the first embodiment of the steam heating device and the rotation of the vortex under the action of steam.

[0032] See figure 2 with image 3 As shown, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com