Pneumatic roll gap instrument

A roll gap meter, pneumatic technology, applied in the field of pneumatic roll gap meter, can solve the problems of easy wear of contacts, delay of production maintenance time, inconvenient maintenance, etc., and achieve the effect of fast and convenient wear and replacement, simple manufacture and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

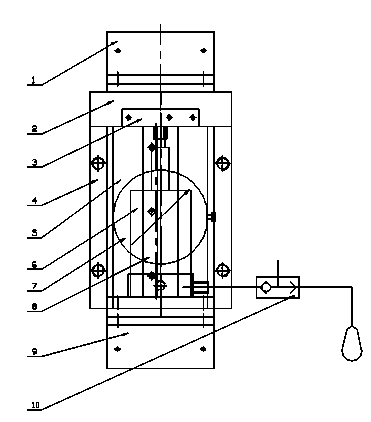

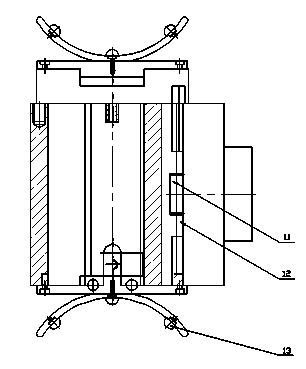

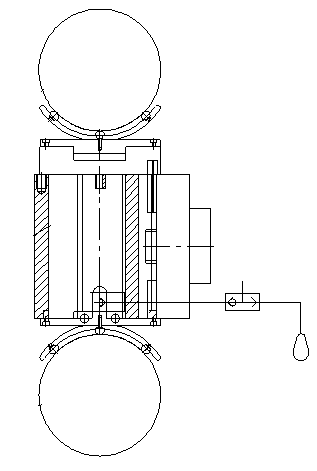

[0012] The technical solutions provided by the present invention will be described in detail below in conjunction with specific examples. It should be understood that the following specific embodiments are only used to illustrate the present invention and are not intended to limit the scope of the present invention.

[0013] like Figure 1 to Figure 3 A pneumatic roll gap meter shown includes a ruler body 4 and a ruler frame 5, the ruler body 4 is connected with the ruler frame 5 through a dovetail groove, wherein the ruler frame 5 can slide up and down on the ruler body 4 ; A single-acting cylinder 6 is provided in the ruler body 4, and the single-acting cylinder 6 is set in the threaded hole of the ruler body 4, wherein the side hole of the ruler body 4 corresponds to the air hole of the single-acting cylinder 6.

[0014] The single-acting cylinder 6 is also connected with a manual air source 10, the piston rod head of the single-acting cylinder 6 is connected with a connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com