New high voltage thyristor valve module

A technology of high-voltage thyristor valve and water inlet pipe, which is applied to electrical components, DC network circuit devices, electrical solid devices, etc., can solve the problem that the cooling water supply system occupies a large space, the local strength of the metal frame structure is low, and the electrical insulation cannot meet the requirements. and other problems, to achieve the effect of compact overall structure layout, stable structure, uniform and effective heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

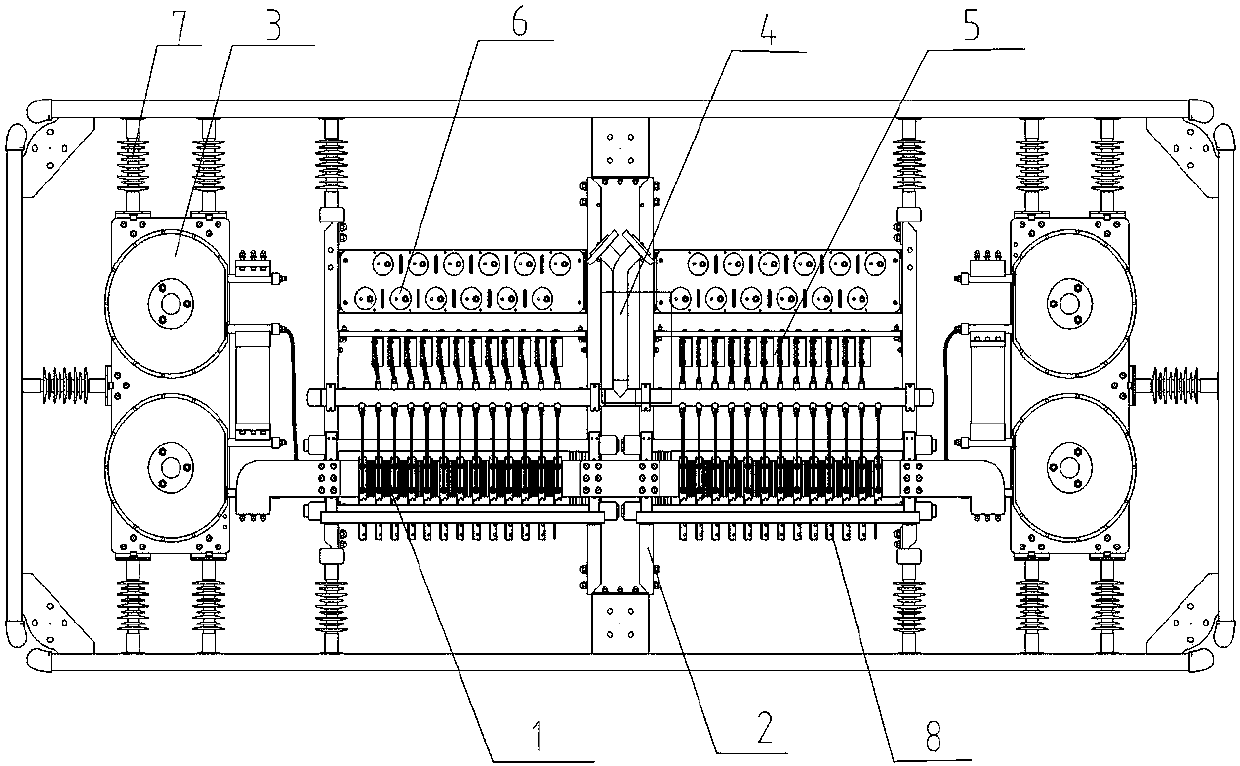

[0015] like figure 1 As shown, a new high-voltage thyristor valve module is mainly composed of a valve stack assembly 1, a metal frame 2, a reactor assembly 3, a water cooling system assembly 4, a water resistance assembly 5 and a damping capacitor assembly 6. The valve stack The component 1, the reactor component 3, the water cooling system component 4, the water resistance component 5 and the damping capacitor component 6 are set and installed in the metal frame 2, and the reactor component 3 is arranged symmetrically on both sides of the metal frame 2, and the water cooling system The assembly 4 is arranged in the middle, and the valve stack assembly 1 , the water resistance assembly 5 and the damping capacitor assembly 6 are symmetrically arranged on both sides of the water cooling system assembly 4 . The water inlet and outlet pipes in the water cooling system component 4 are distributed in staggered layers, and they are separated from the control component 8 on both side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com