Hybrid transmission

A technology of transmission and main transmission, applied in clutches, mechanical drive clutches, magnetic drive clutches, etc., can solve problems such as lack of comfort, and achieve the effect of saving structural space and effectively transmitting force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

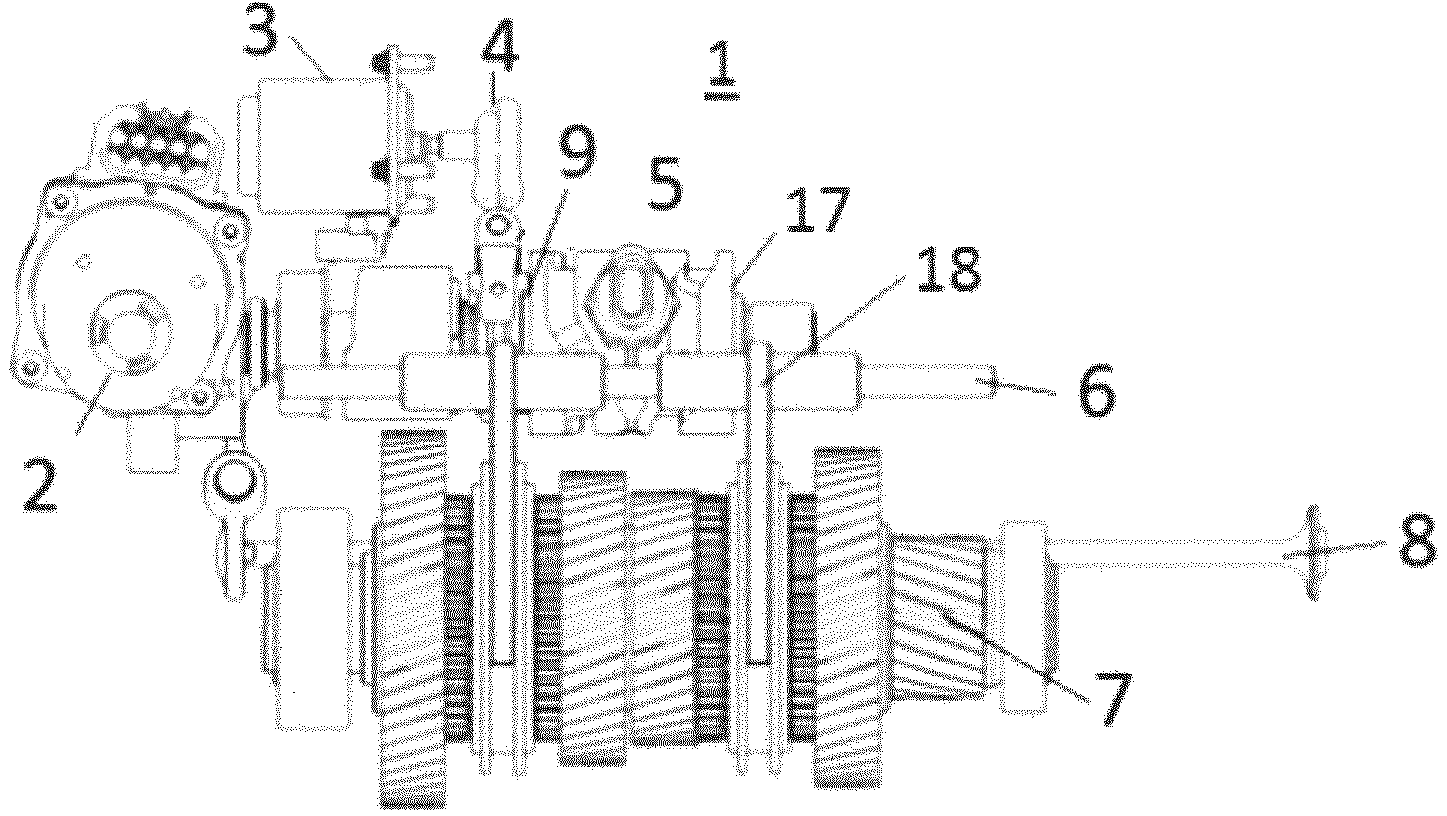

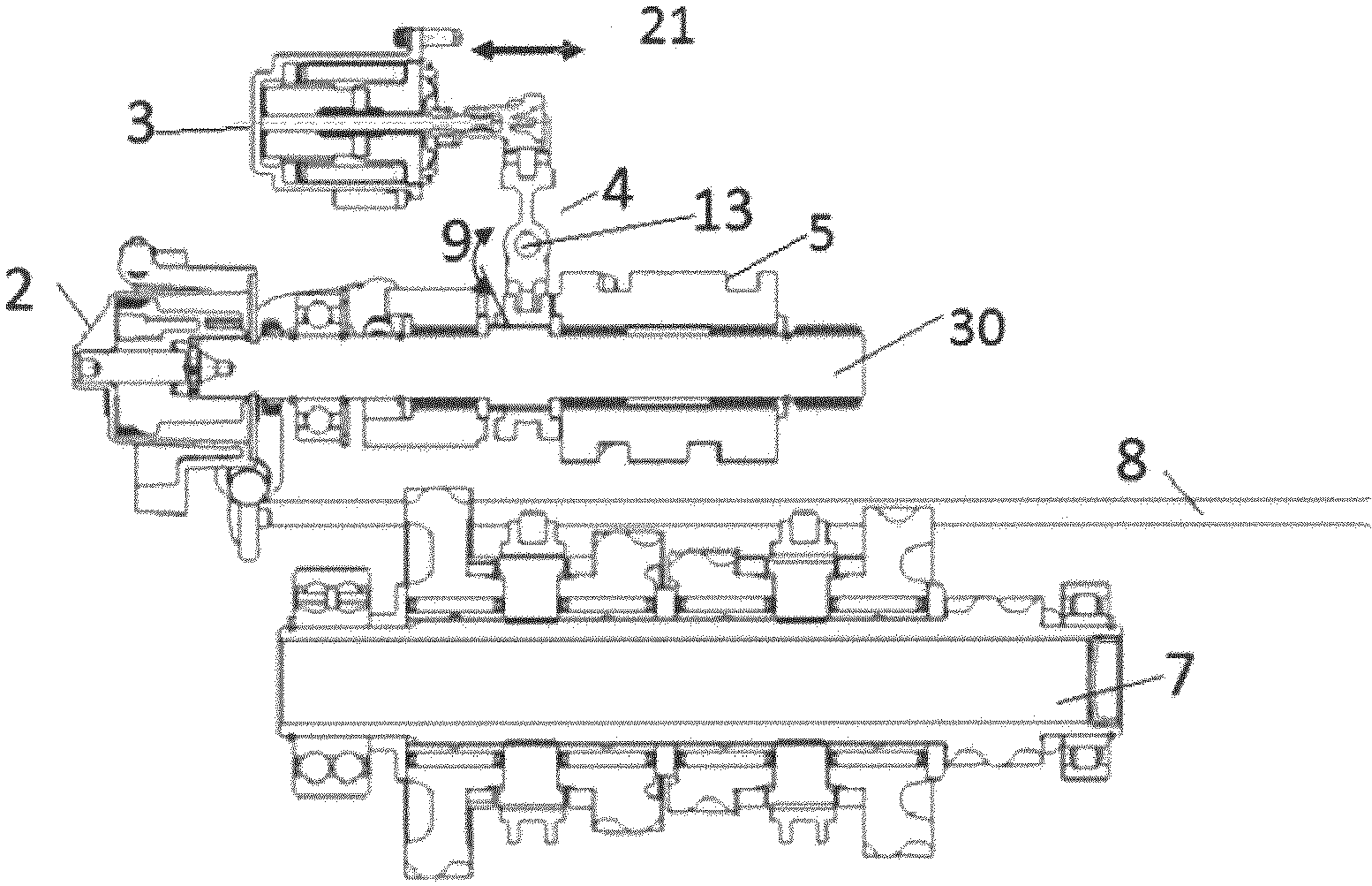

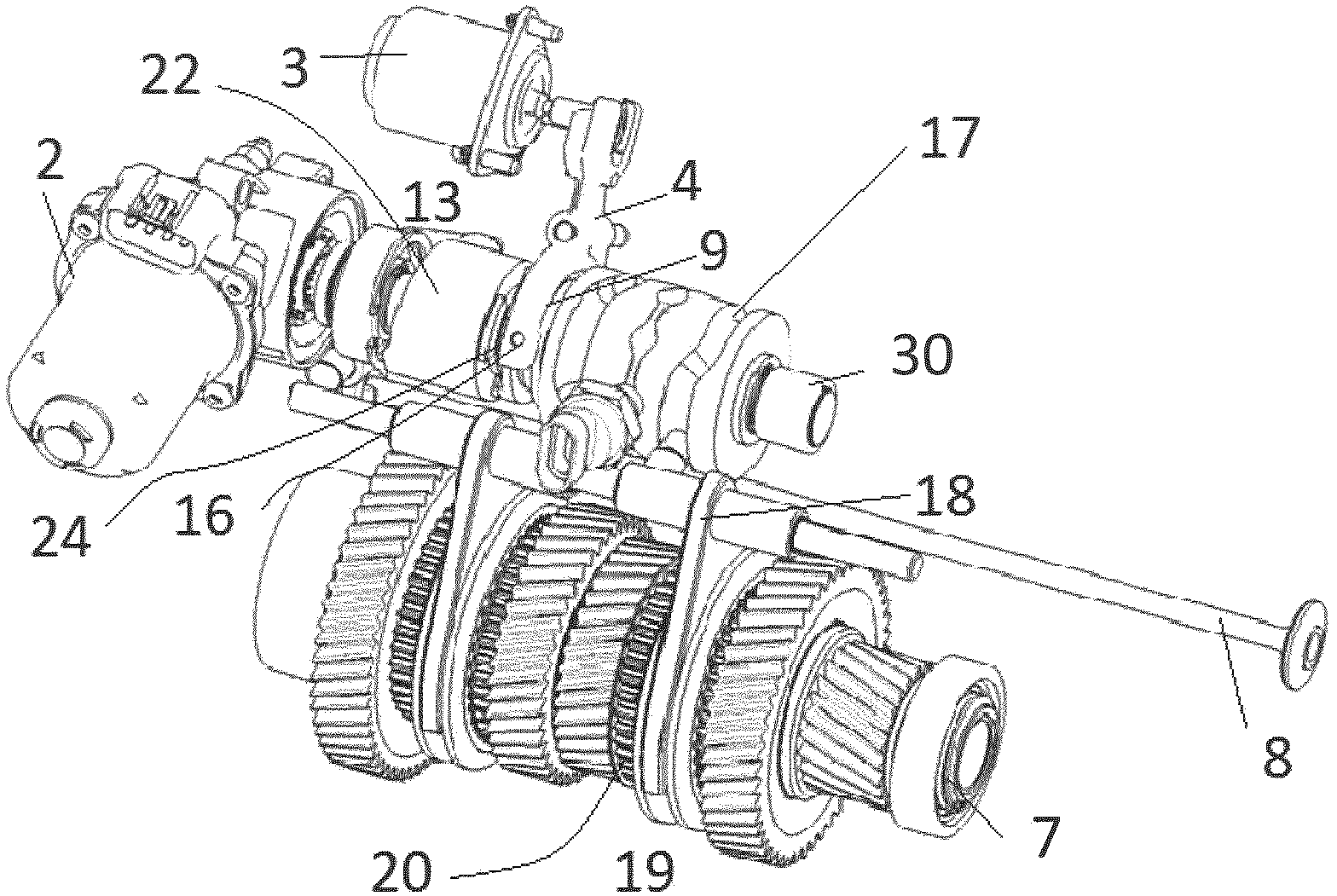

[0019] The figures show a hybrid transmission by way of example, important parts of the transmission, ie the transmission input shaft or layshaft, are not shown. In this type of transmission, the speed ratio is established by the gear pair and the torque is transmitted from the clutch to the transmission input shaft. The gears of each gear stage are installed on the transmission input shaft. The transmission output shaft or the transmission main shaft is arranged coaxially with the transmission input shaft. The gears of the two shaft pairs mesh with each other. Depending on the type of construction, the gears are either fixedly mounted on the shaft or freely rotatable but always axially fixed on the shaft. In order to create a force fit between the shaft and the freely rotating gear, said gear is fastened to the shaft by means of a jaw joint. The jaw engaging device is radially fixed and axially movable on a shaft supporting it. On the rim there is a tooth profile, the cou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com