Machining unit of dotted lines

A point-breaking and hole-cutting technology, which is applied in packaging, transportation and packaging, paper/cardboard containers, etc., can solve the problems of uncontrollable, inaccurate position of handbag stickers and handles, so as to improve efficiency and reduce the time for manual correction , Improve the effect of quality and output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make the above and other objects, features and advantages of the present invention more apparent and comprehensible. The preferred examples are given below, together with the accompanying drawings, for detailed description as follows:

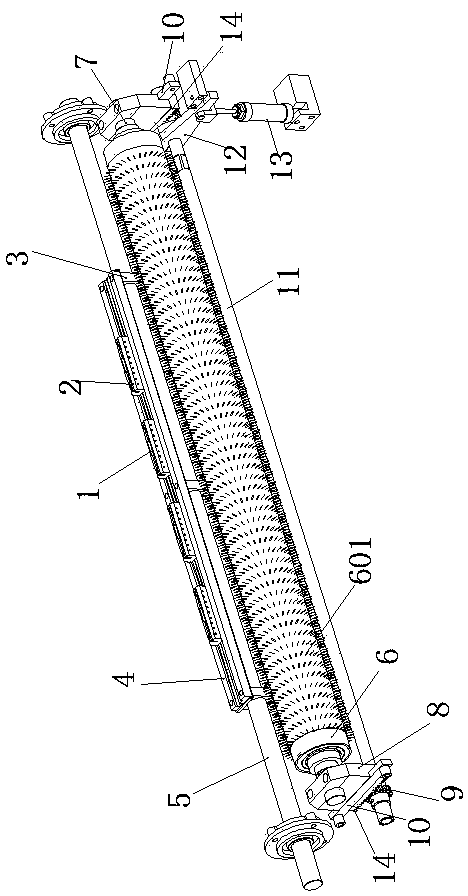

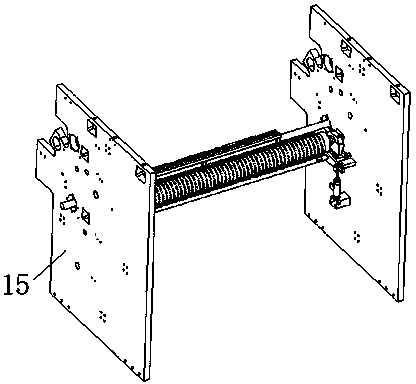

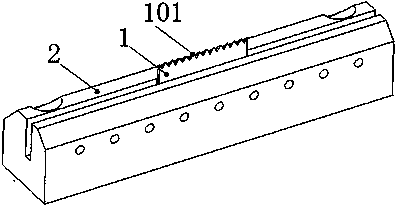

[0017] Such as figure 1 As shown, the point-breaking hole cutting device of the present invention includes a point-breaking knife 1, a point-breaking cutting seat 2, a point-breaking knife rest 3, a point-breaking knife rest plate 4, and a point-breaking shaft 5, and the point-breaking knife rest 3 is provided with On the point breaking shaft 5, the point breaking knife rest plate 4 is fixedly installed on the point breaking knife rest plate 4, and several point breaking cutting seats 2 are installed on the point breaking knife rest plate 4, and the point breaking cutting seat 2 can be mounted on the point breaking knife rest plate 4 The upper axis moves to adapt to paper bags of different sizes and widths, and a point-break...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com