Suspension Arms for Motor Vehicles

A technology for motor vehicles and suspension arms, which is applied in the field of suspension arms for motor vehicles, and can solve the problems of rigidity (insufficient strength, etc.)

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

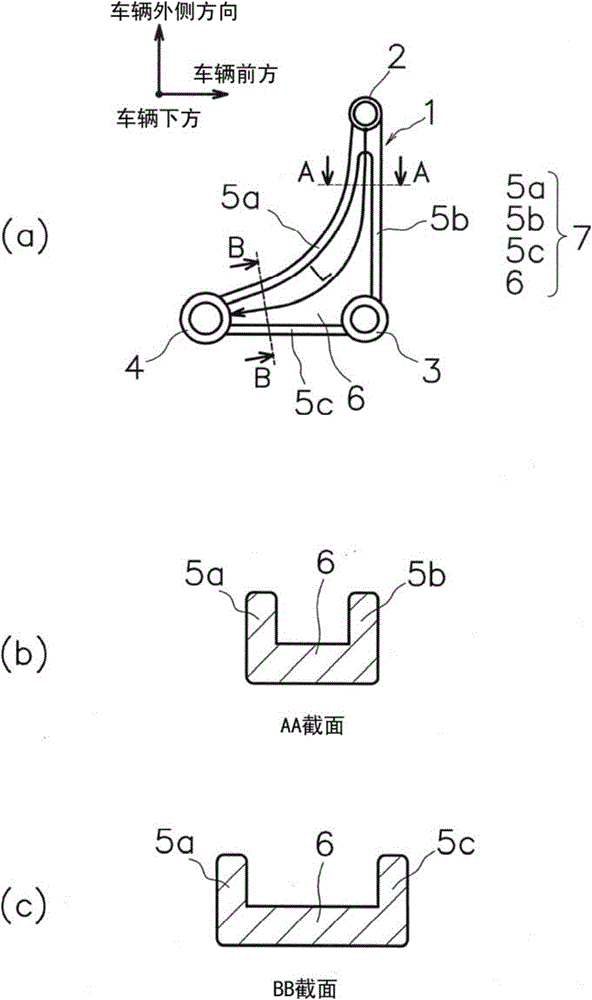

[0056] figure 1 (a) is a top view, (b) is an AA cross-sectional view of the arm, and (c) is a BB cross-sectional view of the arm. exist figure 1 In the coordinate system shown in (a), the "vehicle outer direction" facing upward in the paper refers to, for example, the axle side, and the "vehicle front" facing right in the paper refers to the direction in which the vehicle travels forward as described in the text. , "under the vehicle" in a direction perpendicular to the paper surface refers to a direction in which the vehicle side is viewed from the road surface side under the vehicle. Figure 2 to Figure 8 This definition also applies generically.

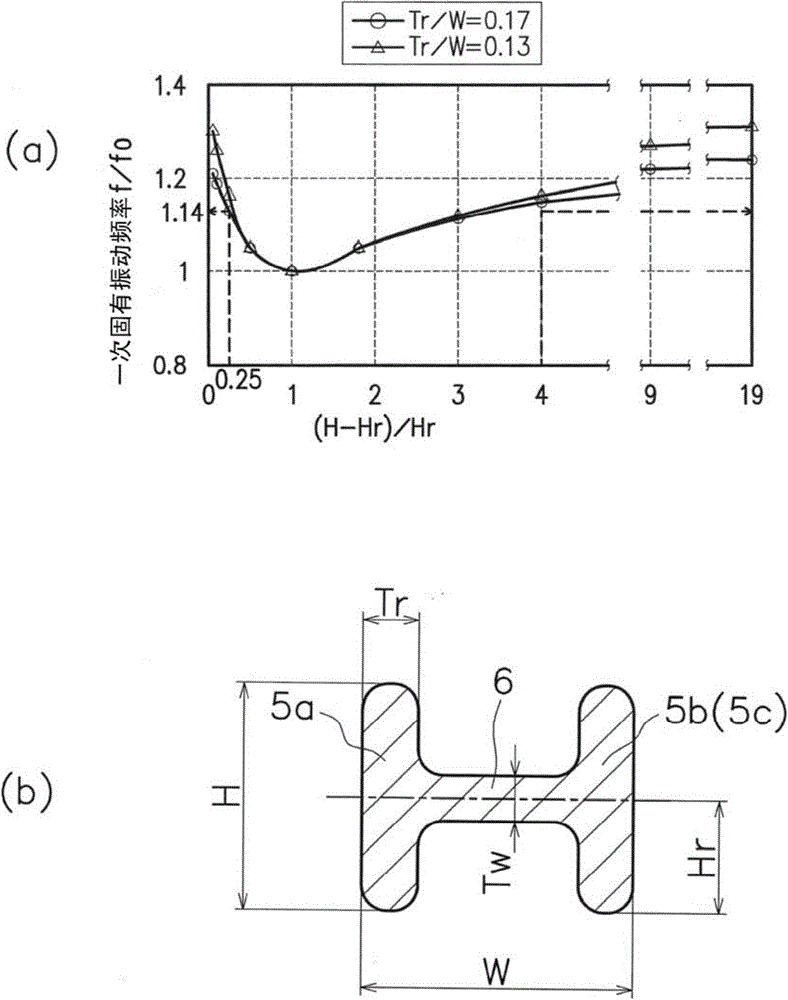

[0057] figure 1In (a), 1 is a suspension arm for a vehicle having an L-shaped arm portion 7 in a plan view, 2 is a ball joint support portion attached to the axle side of the vehicle, and 3 is a vehicle body mounted on the side of the vehicle body. The bush support part A of the side engagement part, 4 is the bush support part...

Embodiment approach 2

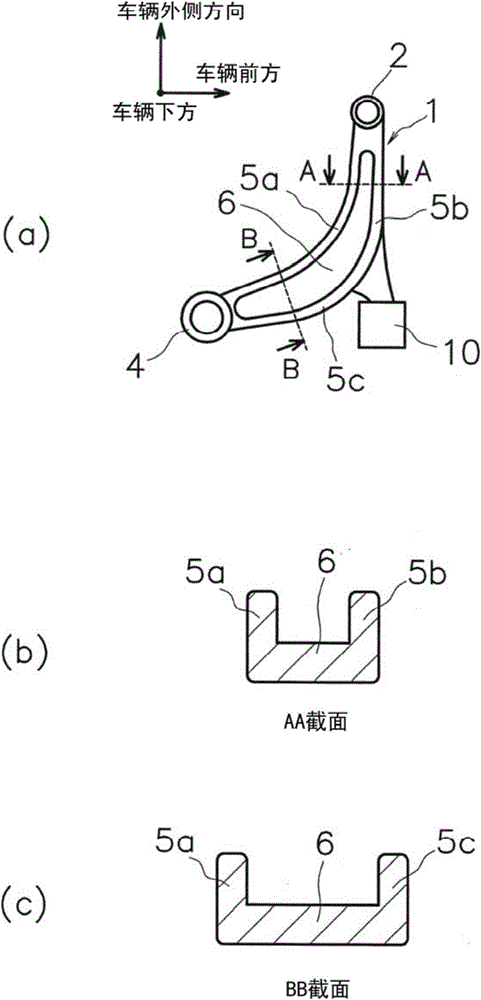

[0068] image 3 A suspension arm for a vehicle according to Embodiment 2 of the present invention (invention example 2 in Table 1 above) having the same U-shaped cross-sectional shape as Embodiment 1 is shown, (a) is a plan view, and (b) is an arm portion AA cross-sectional view, (c) is a BB cross-sectional view of the arm. In the present embodiment, parts based on basically the same technical idea as those in Embodiment 1 are given the same reference numerals and detailed descriptions thereof are omitted, and different parts are described in detail.

[0069] image 3 In (a), 10 is an in-plane bushing support portion C that is attached to the vehicle body side and is coupled to the middle of the arm portion 7 as a vehicle body side engagement portion. Furthermore, in this embodiment, the width of the web 6 in the vicinity of the middle of the arm portion 7 is smaller than in the first embodiment. In this case, even if Tr / W is fixed as in Embodiment 1 and the ratio of (H-Hr)...

Embodiment approach 3

[0071] Figure 4 A suspension arm for a vehicle according to Embodiment 3 of the present invention (invention example 3 in the above-mentioned Table 1) having a U-shaped cross-sectional shape similar to Embodiments 1 and 2 is shown, (a) is a plan view, and (b) is an arm AA sectional view of the part, (c) is a BB sectional view of the arm. In the present embodiment, parts based on basically the same technical idea as those in Embodiment 1 are given the same reference numerals and detailed descriptions thereof are omitted, and different parts are described in detail.

[0072] Figure 4 In (a), 20, 21, 22, 23, 24 are respectively arranged in the above-mentioned figure 1 Shown are holes in the web 6 for lightweighting of the suspension arm for a motor vehicle. In this case, Tr / W was fixed as in Invention Example 1, and the ratio of (H-Hr) / Hr was 19, and a result close to Invention Example 1 was obtained. That is, if 4≦(H-Hr) / Hr≦19 shown in the above formula (2) is satisfied, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com