Embedded engine body sewing bolt structure and assembly technology thereof

A technology for engine body and stitching bolts, applied in the directions of bolts, screws, nuts, etc., can solve the problems of vibration fatigue fracture and vibration load, and achieve the effect of preventing fatigue fracture, improving strength, and facilitating assembly and disassembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

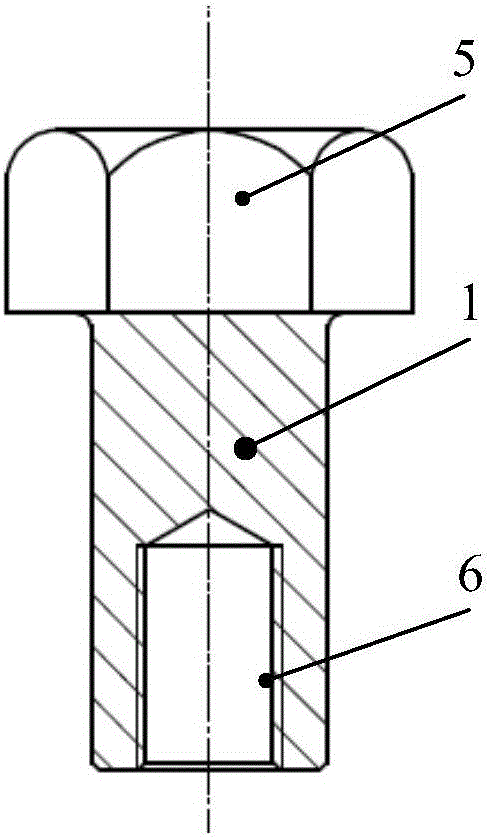

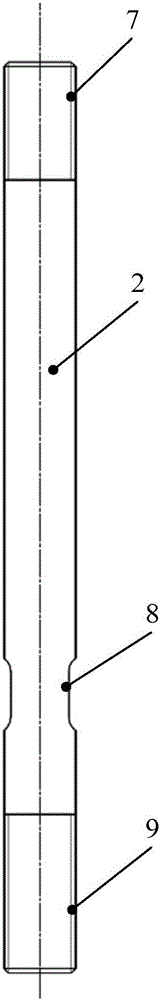

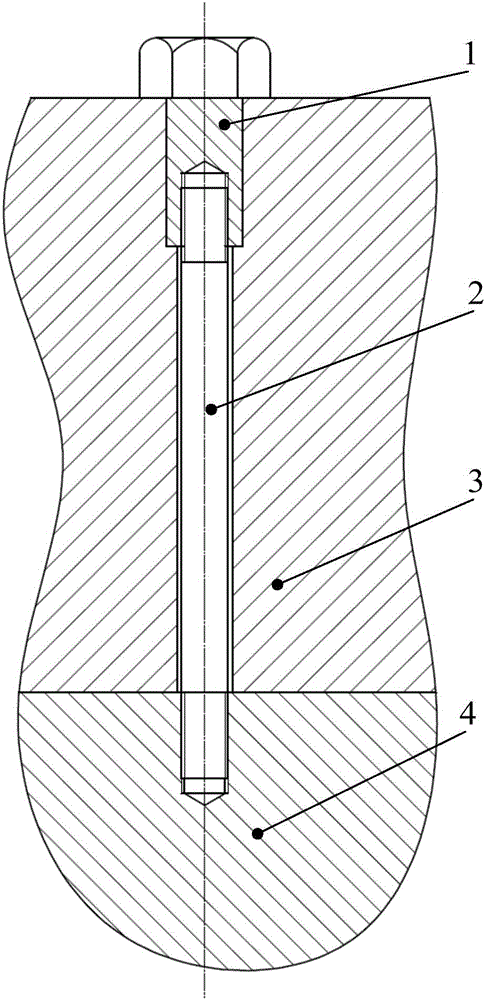

[0024] An embedded engine body stitching bolt structure includes an embedded nut sleeve 1, a screw rod 2, an upper crankcase 3 and a lower crankcase 4. Described embedded nut cover 1 has the nut 5 that is clamped when being used for assembling and dismounting, and described embedded nut cover 1 has the optical axis that is assembled with crankcase 3 on the described embedded nut cover 1, and the optical axis of described embedded nut cover 1 There is a threaded blind hole 6 assembled with the thread 7 of the screw rod 2, and the nut 5 of the embedded nut sleeve 1 and the optical axis transition part have a transition fillet, such as figure 1 As shown; one end of the screw rod 2 has an upper external thread 7 that is assembled with the threaded blind hole 6 of the embedded nut sleeve 1, and the other end of the screw rod 2 has a lower outer thread that is assembled with the threaded hole of the lower crankcase 4. Thread 9, the polished rod portion of the screw 2 near the side o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com