D-pillar upper joint structure

A technology of joint structure and plate connection, which is applied in the direction of superstructure, superstructure subassembly, and connection between superstructure subassemblies, can solve the problems of tailgate frame deformation, poor torsional rigidity, fatigue cracking, etc., and achieve improvement Effects of torsional moment of inertia and torsional stiffness, avoidance of resonance and abnormal noise, and improvement of natural vibration frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

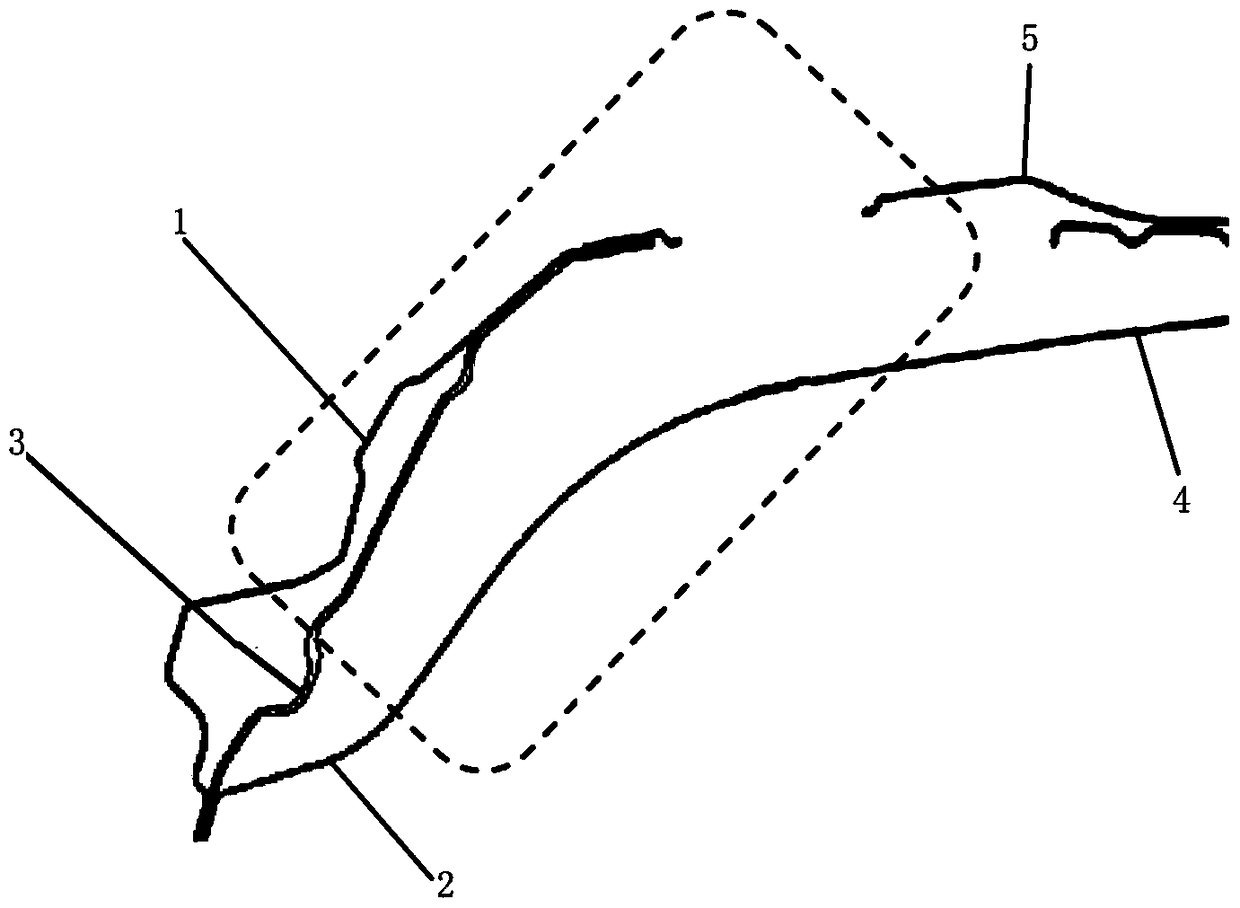

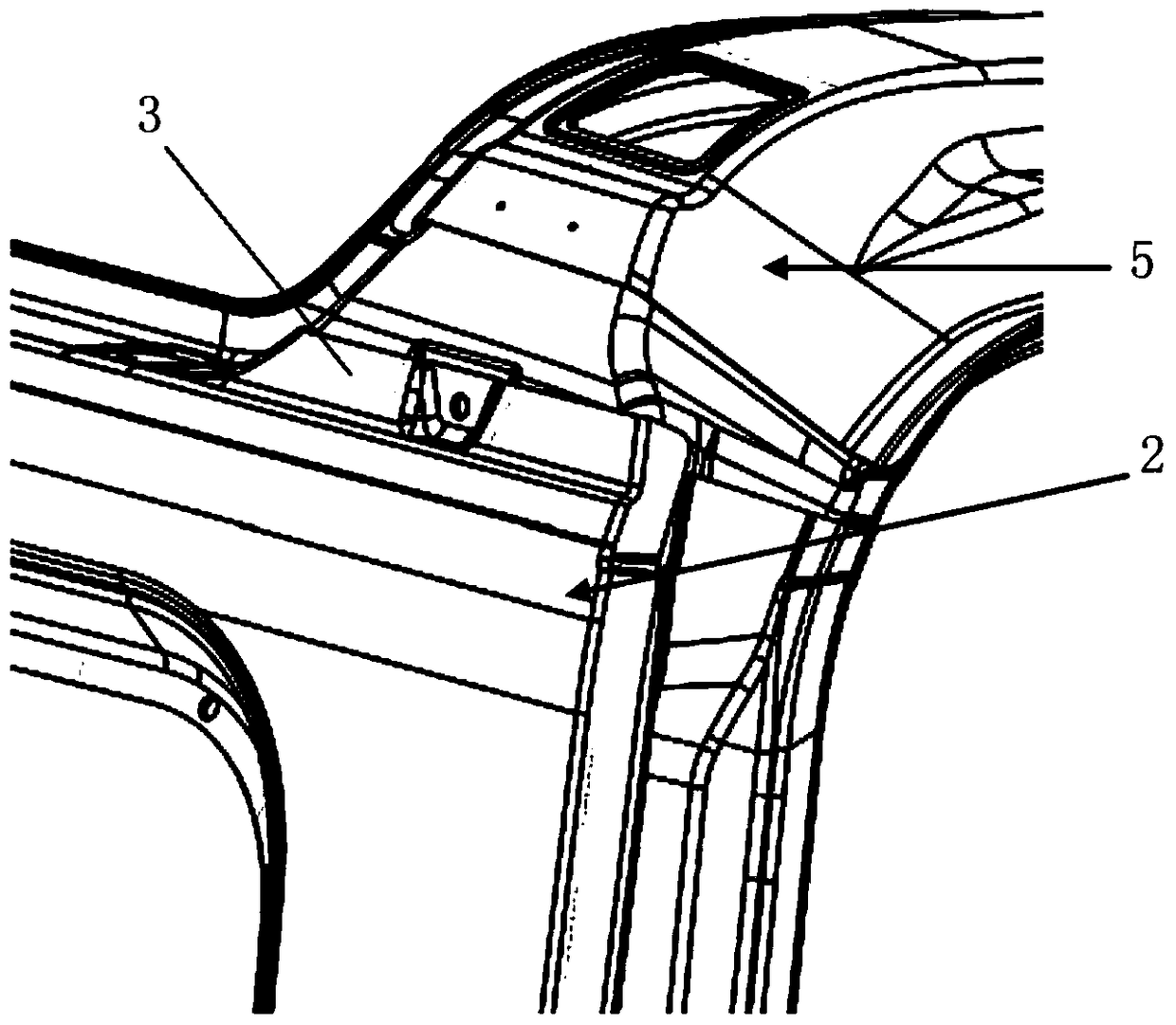

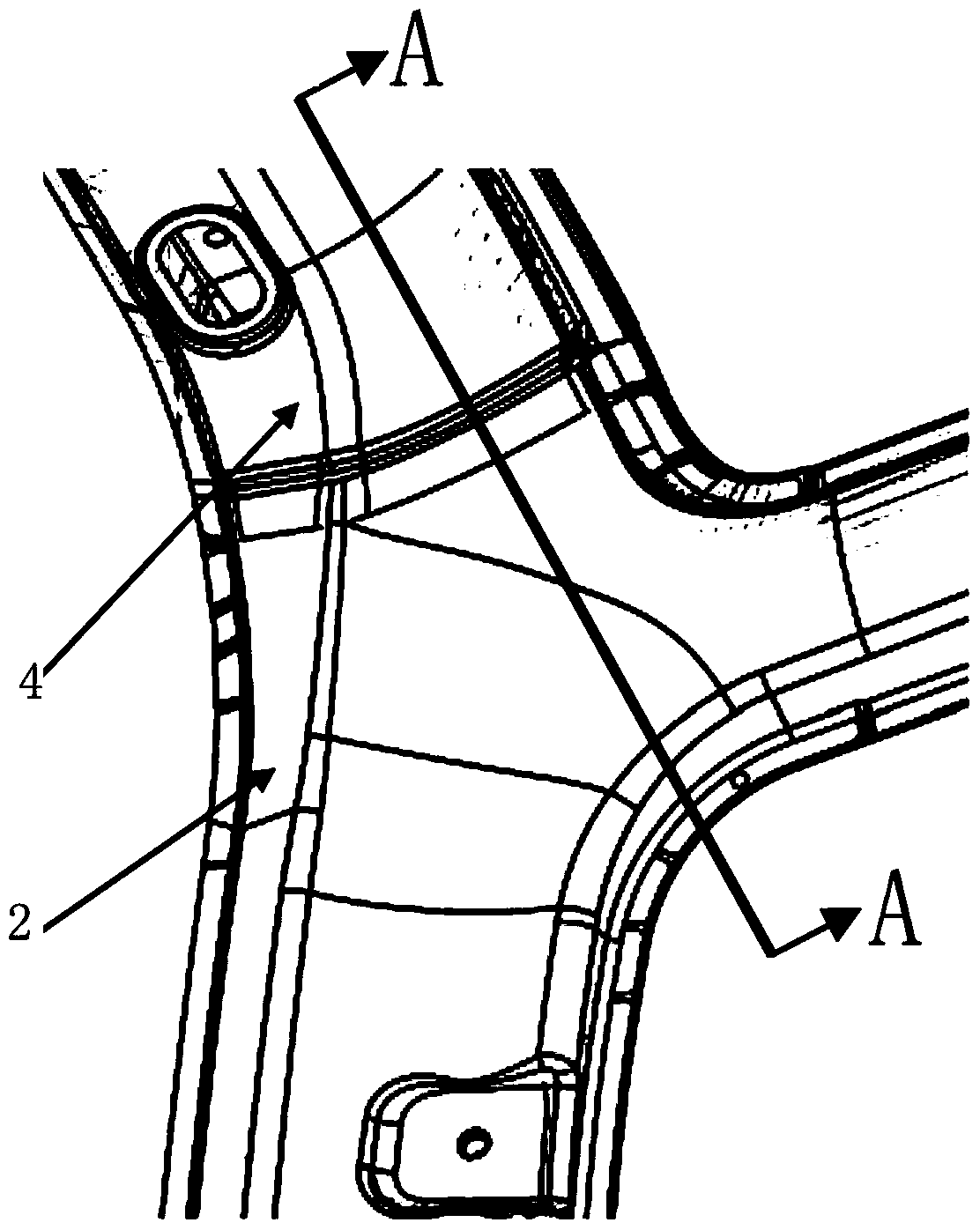

[0023] The following with attached Figure 1 to Figure 5 The joint structure on the D-pillar of the present invention will be further described in detail.

[0024] For the joint structure on the D-pillar of the present invention, please refer to Figure 1 to Figure 5 , including a side wall outer panel 1, a side wall inner panel 2, a D-pillar upper reinforcing plate 3, a roof rear beam outer panel 5, a roof rear beam inner panel 4, the D-pillar upper reinforcement plate 3 and the side wall The outer panel 1 is connected at the head and tail sides, the side wall inner panel 2 is connected to the opposite side of the roof rear beam inner panel 4, the side wall inner panel 2 is connected to the end of the D-pillar upper reinforcement plate 3, and the roof The rear crossbeam outer panel 5 is connected to the head end of the side wall outer panel 1, and also includes a D-pillar reinforcing plate 6, which is a frame-shaped plate with an opening 10 on one side, and the D-pillar Rei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com