Multipurpose ship berthing device

A multi-purpose, ship-based technology, applied in ship cleaning devices, ship hulls, ship construction, etc., can solve problems such as large impact force of tires, frictional collision between ship hull and wharf, water pollution, etc., to increase friction coefficient, improve safety, The effect of reducing the impact force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

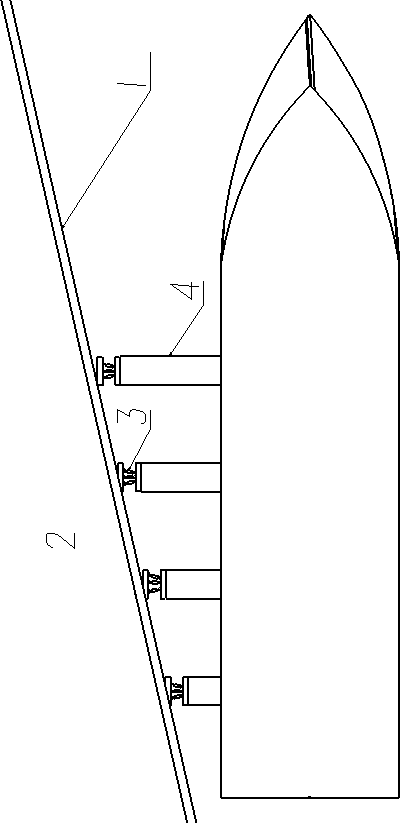

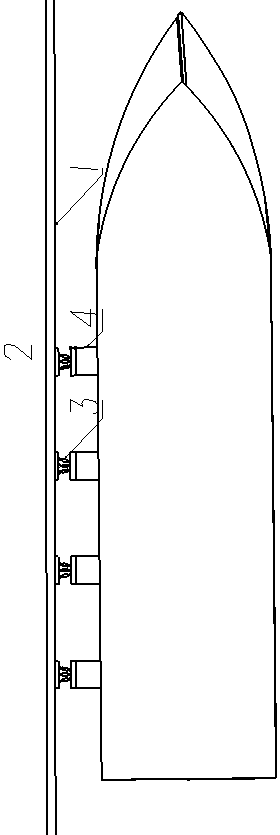

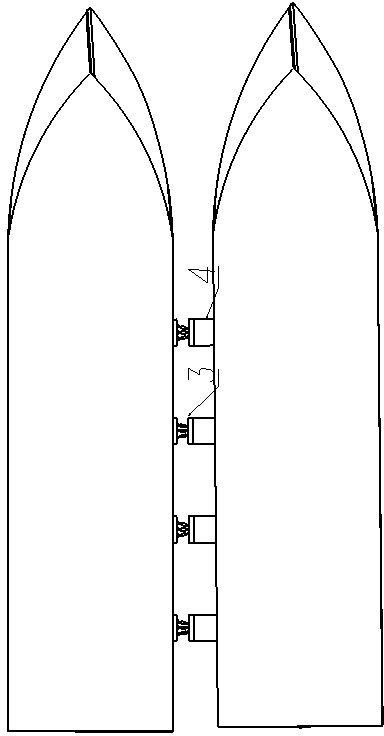

[0021] See figure 1 , which is a schematic diagram of a berthing dock for a multi-purpose ship berthing device according to the present invention, including a hull, a primary decompression device and a secondary decompression slow pulling device 3, and the primary decompression device includes one or A plurality of double-acting single-piston oil cylinders, and a control room is installed in the hull. The piston rod 4 of each double-acting single-piston oil cylinder can extend out of the hull and be adsorbed on the outer steel plate (or magnetic adsorption device) 1 of the wharf 2. The outer end of the piston rod 4 is fixed with an electromagnet 5, and the expansion and contraction of the piston rod 4 in each double-acting single-piston oil cylinder and whether the electromagnet 5 is energized are controlled by the hydraulic system.

[0022] The laser displacement sensor is installed on the secondary decompression and slow pulling device 3, and the distance and speed signals o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com