Air bearing part fit testing equipment

A technology of air bearing and testing equipment, applied in the direction of mechanical bearing testing, etc., to achieve the effect of good flexibility, reducing the impact of environmental noise, and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with embodiments. The following embodiments are for explaining the present invention and the present invention is not limited to the following embodiments.

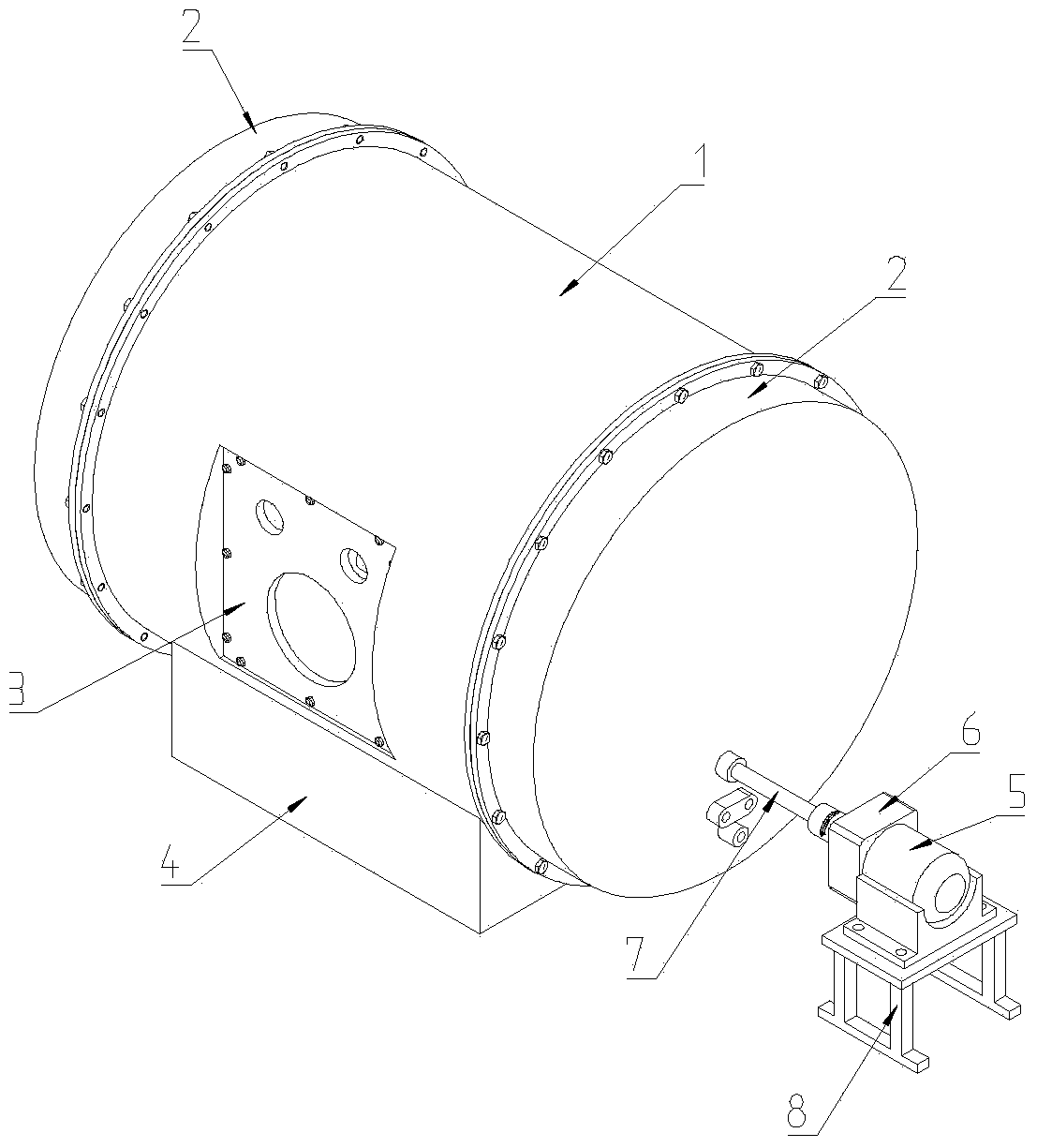

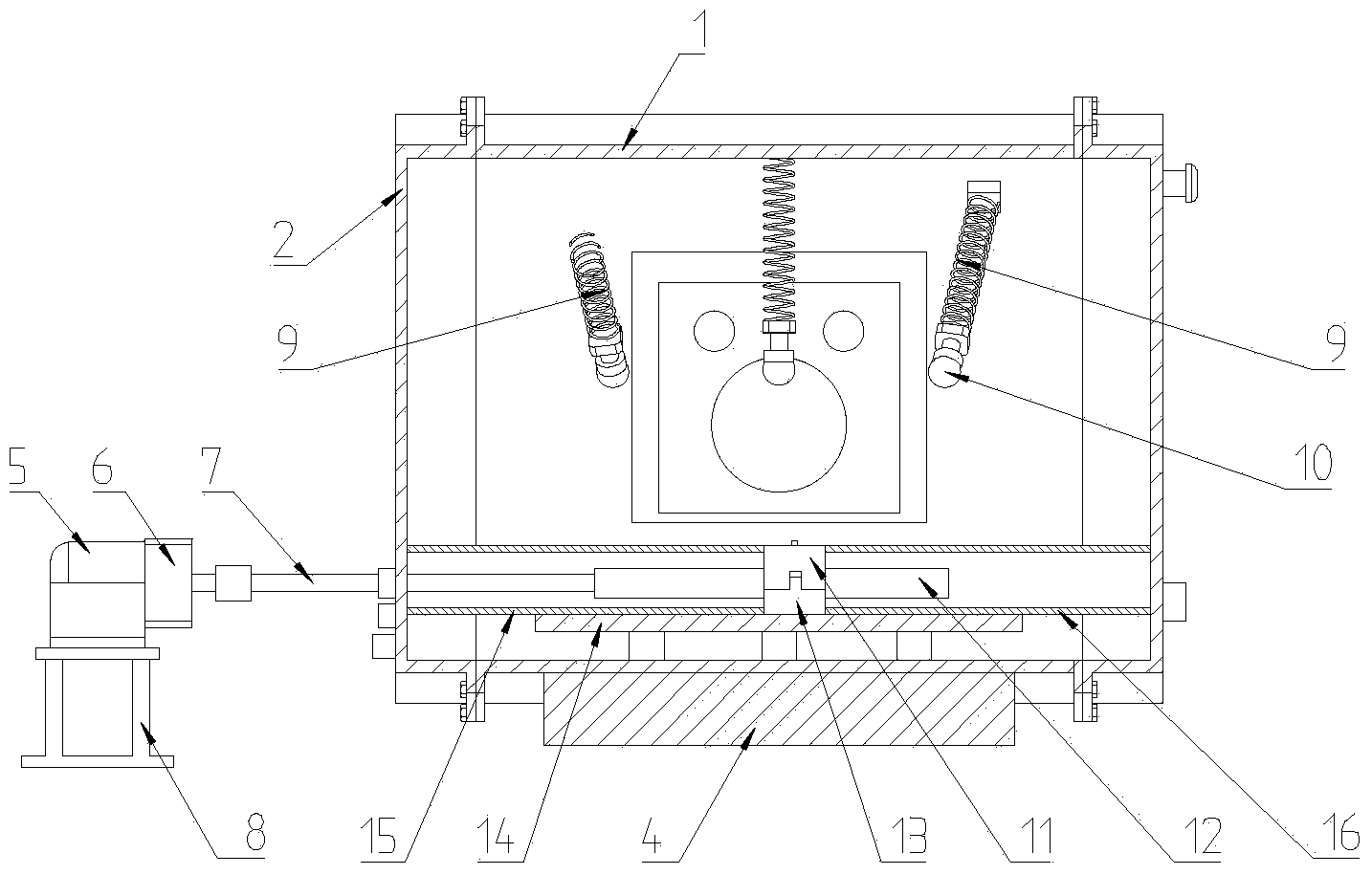

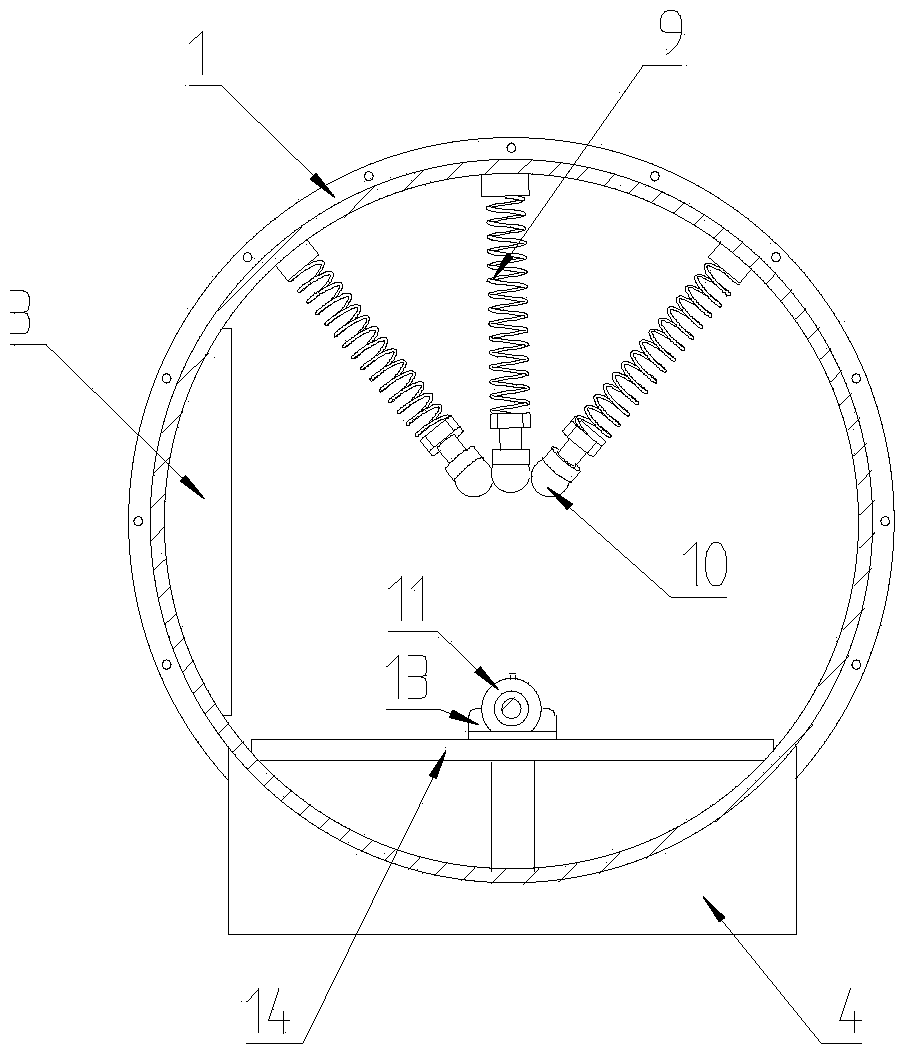

[0021] Such as Figure 1~3 As shown, an air bearing parts matching testing equipment includes a tank body, an observation window 3, a shock isolation base 4, a drive motor 5, a reducer 6, a drive shaft 7, a bracket 8, a microphone 10, and a metal hose 9, The support 13, the installation platform 14, the soundproof pipe, and the air supply pipe. The soundproof pipe includes a first soundproof pipe 15 and a second soundproof pipe 16. The tank body includes a tank body 1 and a tank cover 2, and the inner wall of the tank body is coated with sound-absorbing material , The can body 1 is cylindrical, and there are two can lids 2 installed at both ends of the can body 1, and an observation window 3 is provided on the can body 1.

[0022] The instal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com