Phase shift mask and method of making the same, array substrate and method of making the same

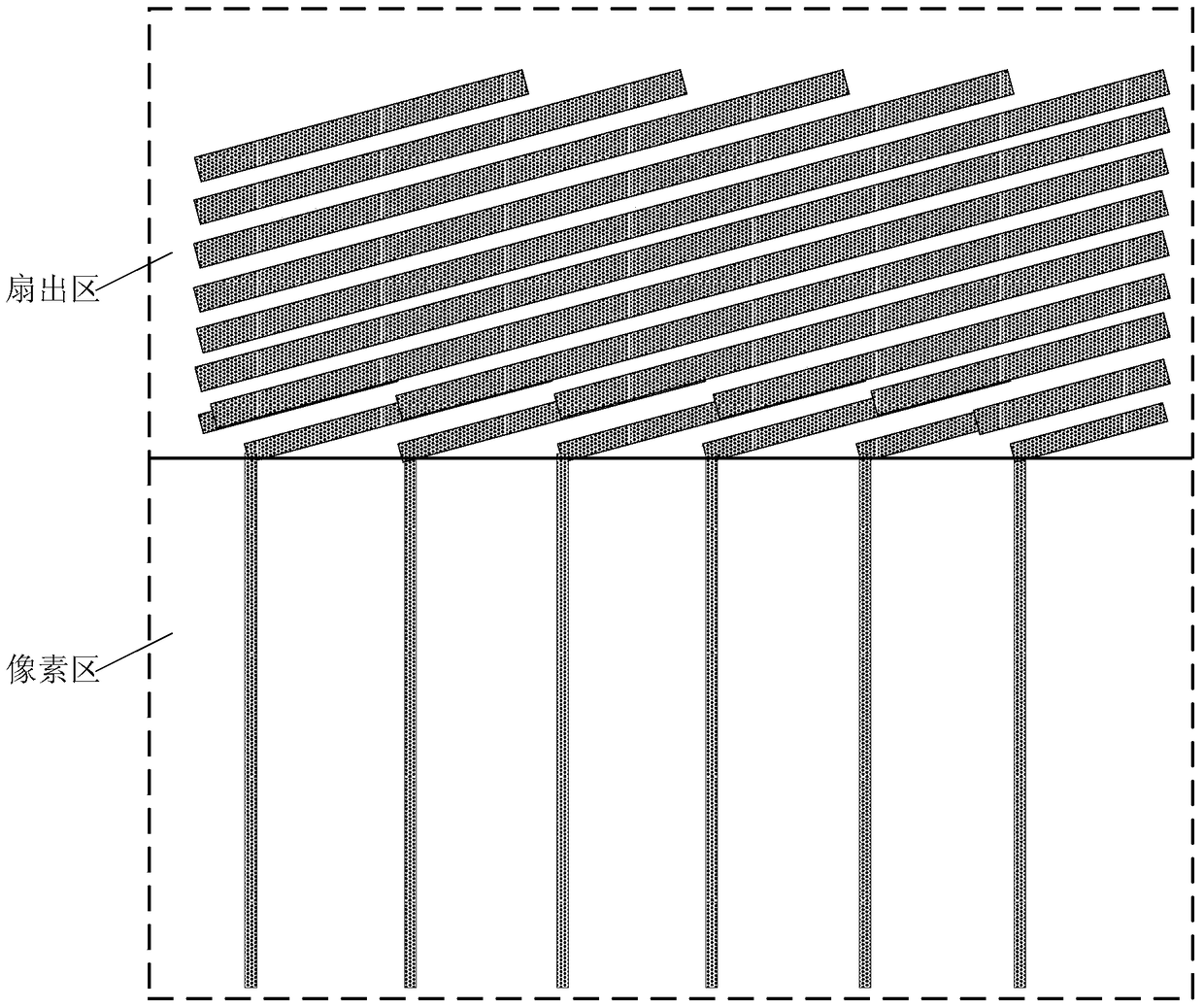

An array substrate and phase-shift mask technology, which is applied in the field of phase-shift mask and its manufacturing method, array substrate and its manufacturing, can solve the problem of dense signal lines in the fan-out area and sparse signal lines in the pixel area, etc. problem, achieve the effect of reducing the line width difference and reducing the difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0082] The manufacturing method of the phase-shift mask plate of the present embodiment comprises the following steps:

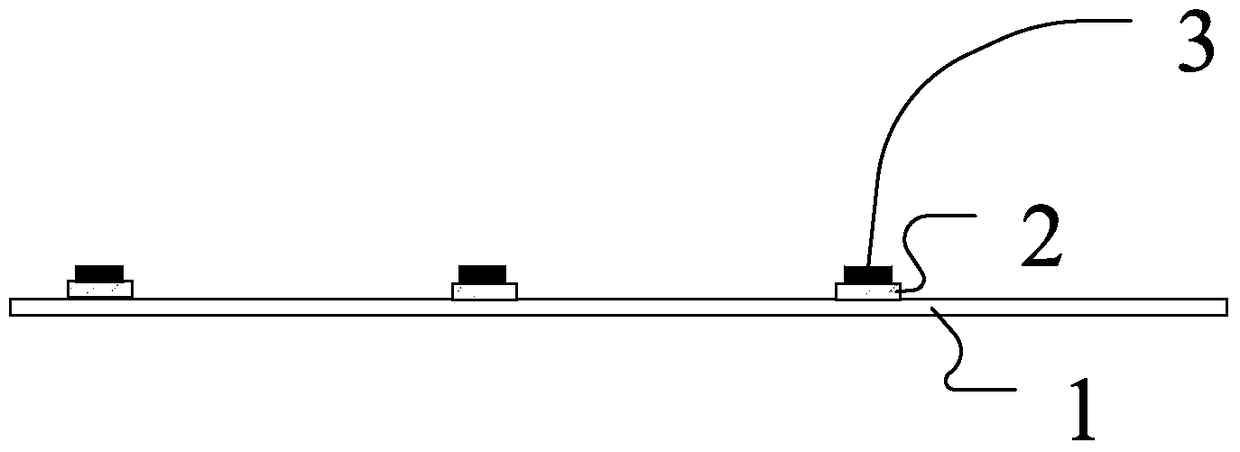

[0083] Step a1, such as Figure 8 As shown in (1), a substrate 1 is provided, and the substrate 1 may be a glass substrate or a quartz substrate. On the substrate 1, a phase shift layer 2 and an opaque layer 3 are sequentially formed, the material of the opaque layer 3 is chromium, and a photoresist 4 is coated on the opaque layer 3;

[0084] Step a2, such as Figure 8 As shown in (2), remove the photoresist outside the light-shielding pattern area after development, and etch the phase shift layer 2 and the light-impermeable layer 3 outside the light-shielding pattern area by dry etching;

[0085] Step a3, such as Figure 8 As shown in (3), the remaining opaque layer 3 is etched and thinned by a wet etching process;

[0086] Step a4, such as Figure 8 Shown in (4), remove remaining photoresist;

[0087] Step a5, such as Figure 8 Shown in (5), coat ph...

Embodiment 2

[0093] The manufacturing method of the phase-shift mask plate of the present embodiment comprises the following steps:

[0094] Step b1, such as Figure 8 As shown in (1), a substrate 1 is provided, and the substrate 1 may be a glass substrate or a quartz substrate. On the substrate 1, a phase shift layer 2 and an opaque layer 3 are sequentially formed, the material of the opaque layer 3 is chromium, and a photoresist 4 is coated on the opaque layer 3;

[0095] Step b2, such as Figure 8 As shown in (2), remove the photoresist outside the light-shielding pattern area after development, and etch the phase shift layer 2 and the light-impermeable layer 3 outside the light-shielding pattern area by dry etching;

[0096] Step b3, such as Figure 8As shown in (3), the remaining opaque layer 3 is etched and thinned by a wet etching process;

[0097] Step b4, such as Figure 8 Shown in (4), remove remaining photoresist;

[0098] Step b5, such as Figure 8 Shown in (5), coat pho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com