Manufacturing method of fusing device

A technology of fuses and devices, which is applied in the field of preparation of fuse devices, can solve problems such as diode chip defects, and achieve the effects of reducing the number of times of exposure, eliminating defects, and reducing the number of times of corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] Combining the above core ideas, the present invention provides a method for preparing a fuse device, comprising the following steps:

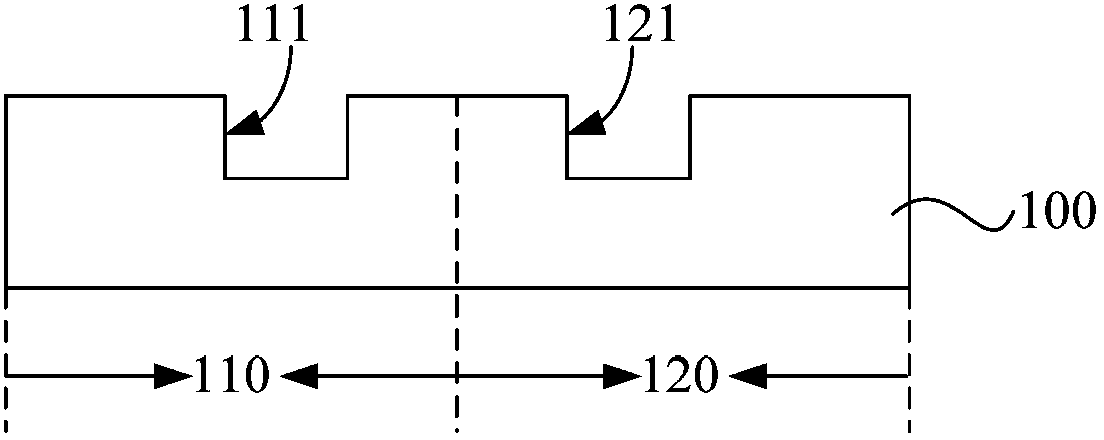

[0037] Step S01, providing a substrate, the substrate has a pad area and a fuse area, the pad area has a pad, and the fuse area has a fuse;

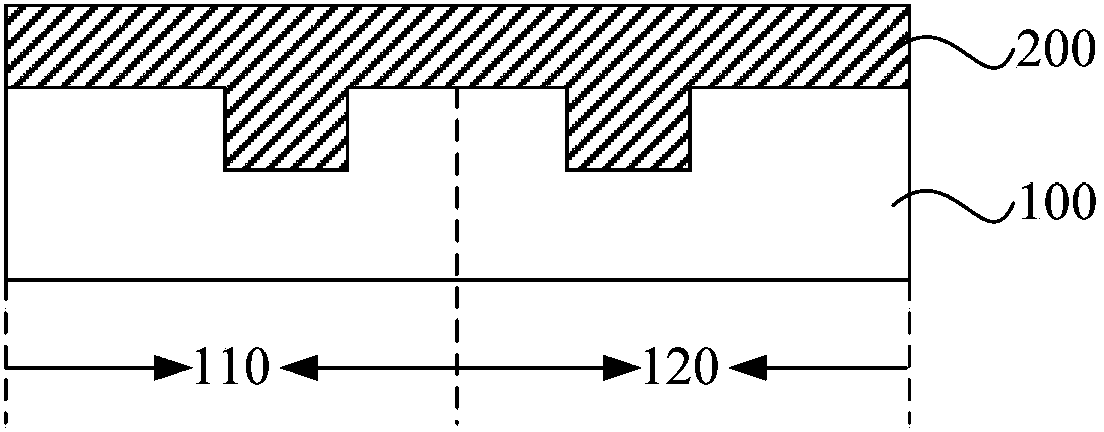

[0038] Step S02, preparing a passivation layer on the substrate;

[0039] Step S03 , removing part of the thickness of the passivation layer of the fuse region, so that the passivation layer above the fuse remains to a predetermined thickness;

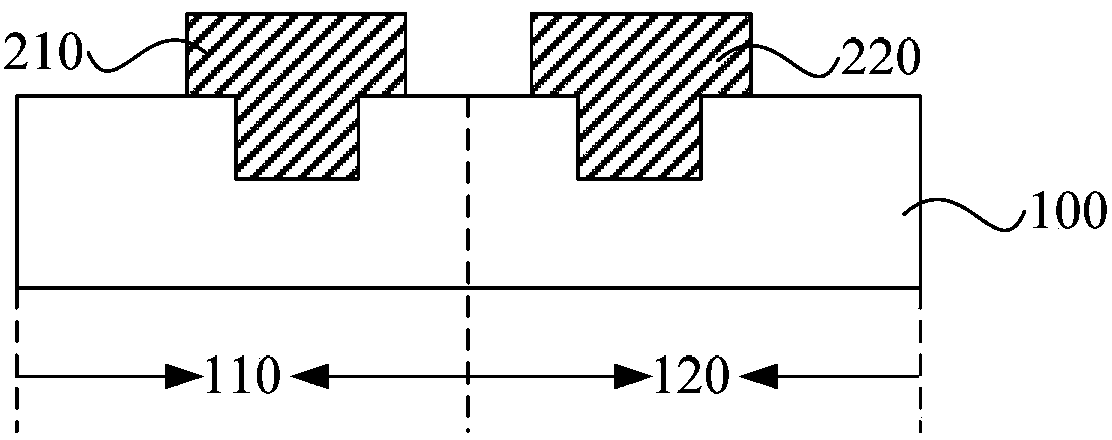

[0040] Step S04 , selectively removing the passivation layer in the pad region to expose the pad.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com