Telechelic polyolefin and preparation thereof

A polyolefin, telechelic technology, applied in the fields of compounds containing elements of Group 3/13 of the periodic table, organic chemistry, chemical instruments and methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0078] The following examples relate to the preparation:

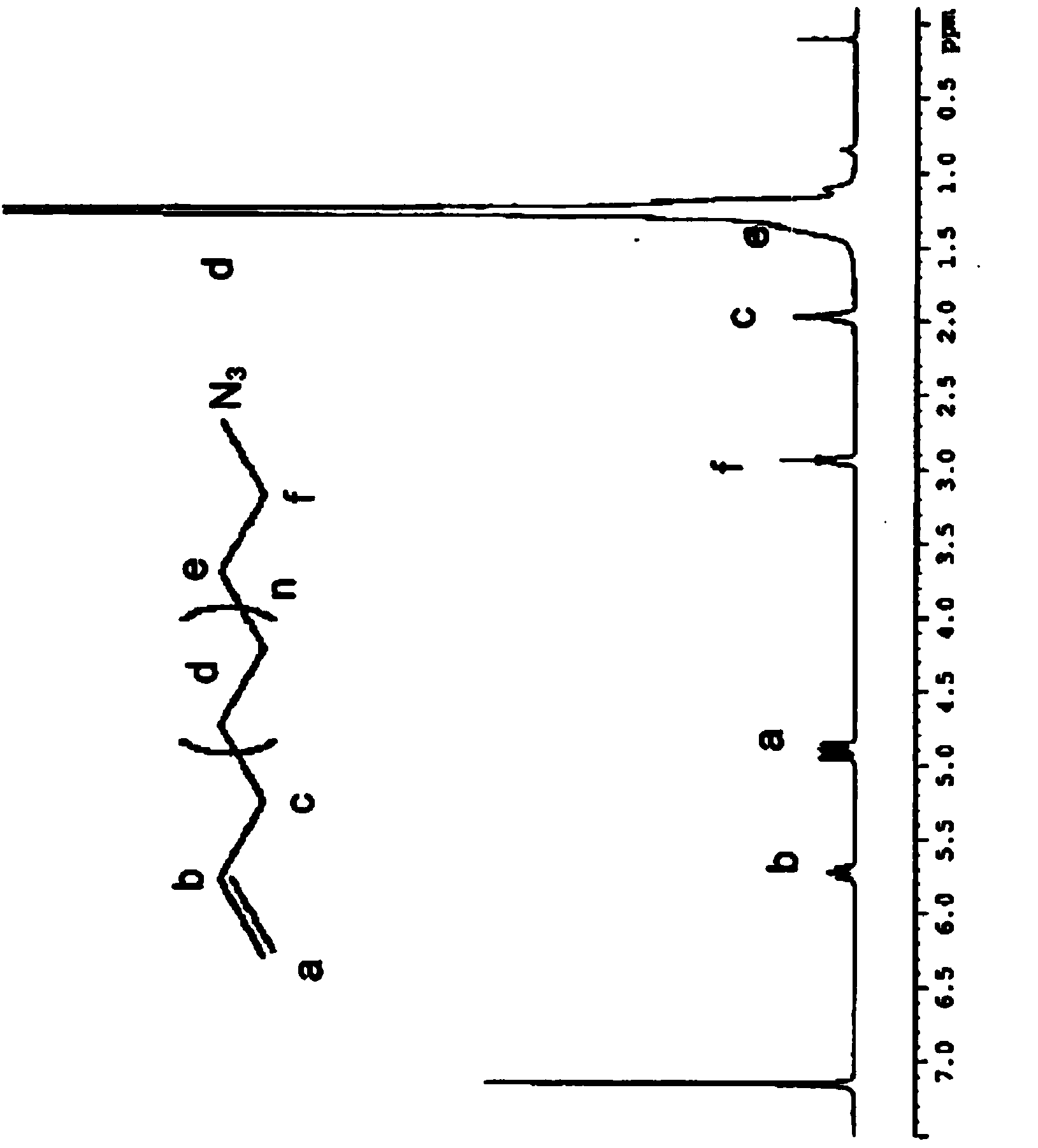

[0079] - a transfer agent of formula (III);

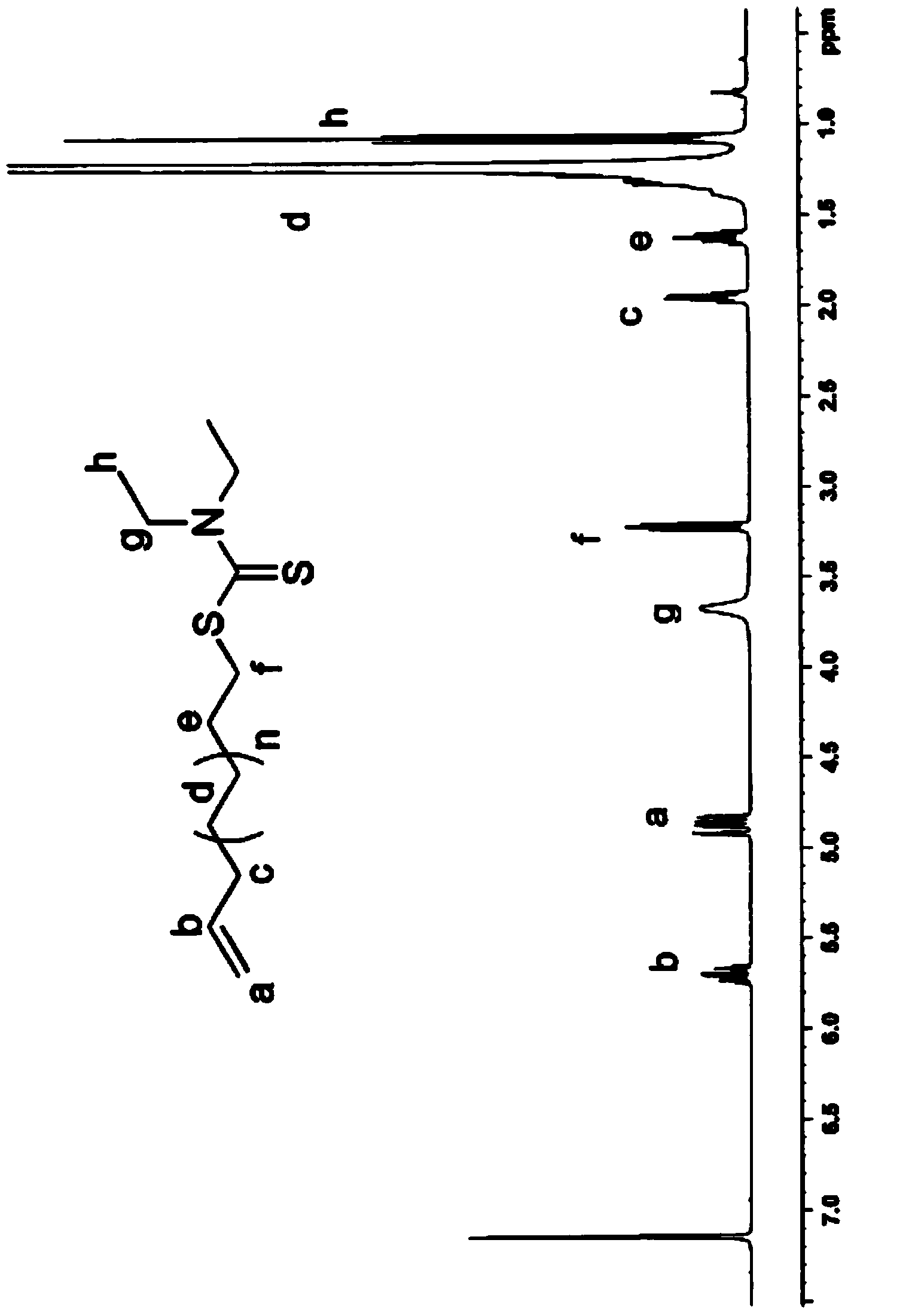

[0080] - an intermediate compound of formula (II);

[0081] - A telechelic polyolefin of formula (I).

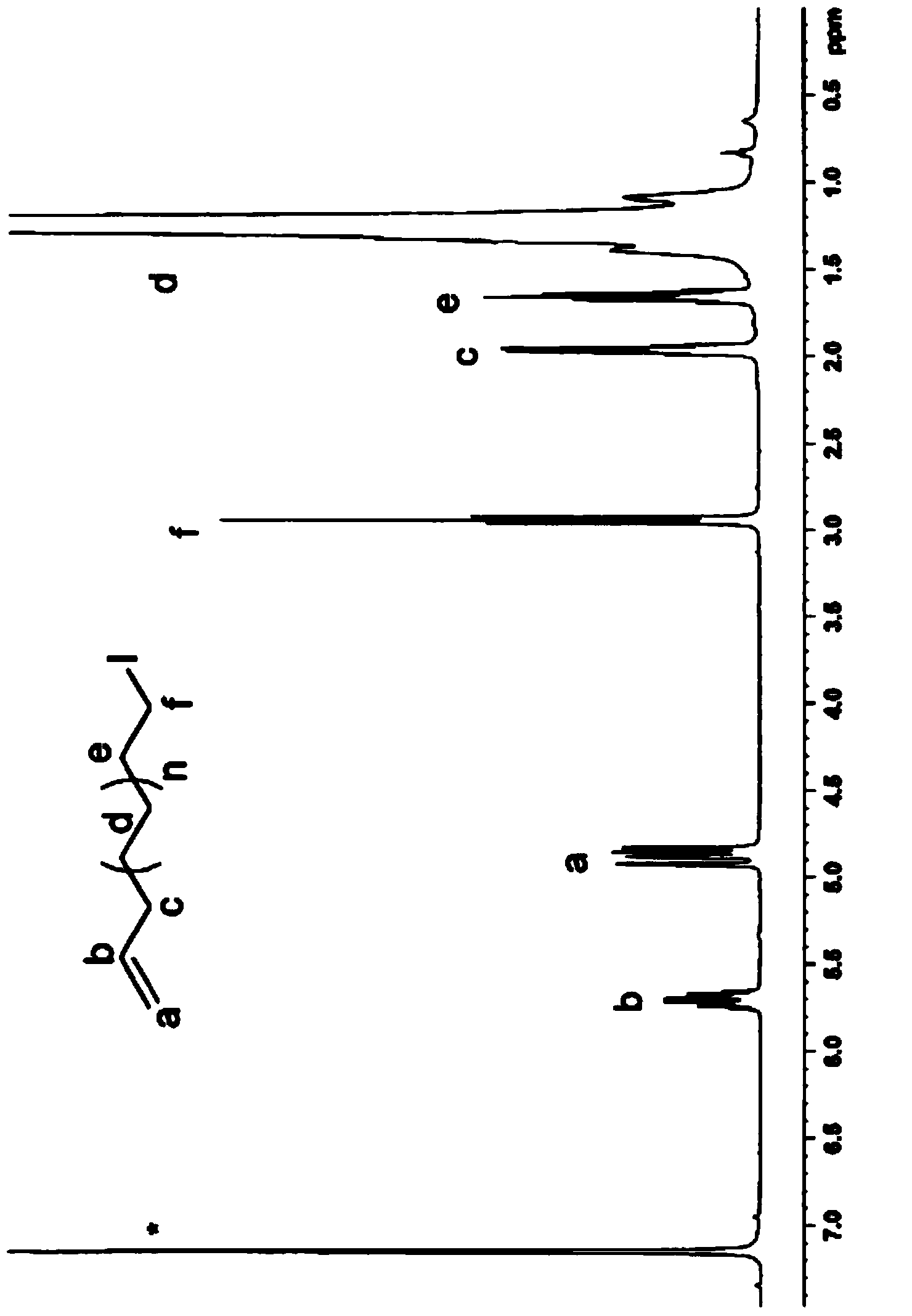

[0082] Transfer agent bis(10-undecenyl)magnesium (Mg((CH 2 ) 9 CH=CH 2 ) 2 )Synthesis

[0083] To a suspension of magnesium (2.38 g, 98 mmol) in di-n-butyl ether (100 ml) was added 11-bromo-1-undecene (11.3 ml, 49 mmol) dropwise at 0°C. The reaction mixture was stirred at 0°C for 1 hour and then allowed to warm to room temperature. The resulting suspension was filtered to remove excess magnesium. Dioxane (5.0ml, 59mmol) was added to the filtrate, immediately after which a white precipitate formed. The suspension was stirred for 2 hours, then filtered to obtain Mg((CH 2 ) 9 CH=CH 2 ) 2 Solution in di-n-butyl ether. An aliquot was taken from the solution for concentration determination by titration using i) pyrene-1-acetic acid and ii) HCl(aq) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molar mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com