Preparation technology for hotpot condiment

A preparation process and technology of hot pot bottom material, which is applied in the field of preparation technology of hot pot bottom material, can solve the problem of high cholesterol content, achieve the effect of rich nutrition, improved nutritional performance, and red and bright soup color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] The preparation technology of this chafing dish bottom material comprises the following steps:

[0017] 1. Put 100g of butter, 120g of rapeseed oil, 100g of soybean oil, 100g of peanut oil, and 80g of hazelnut oil into a pot and heat to 70°C to obtain the first mixture.

[0018] 2. Add 45 g of glutinous rice cake peppers to the first mixture, stir evenly to obtain the second mixture, and heat the second mixture to 105°C.

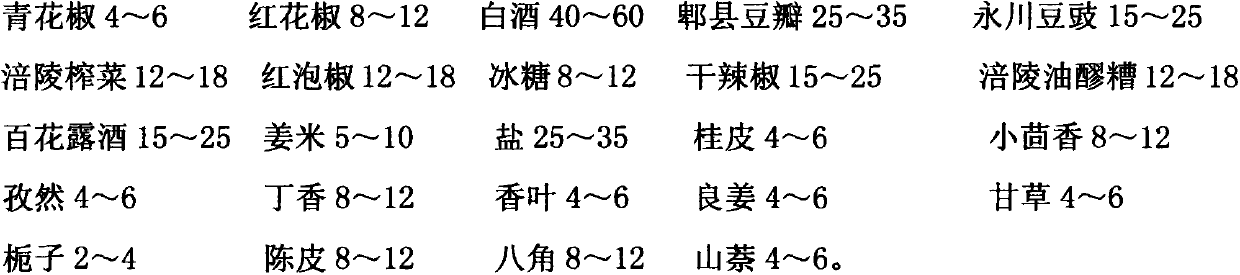

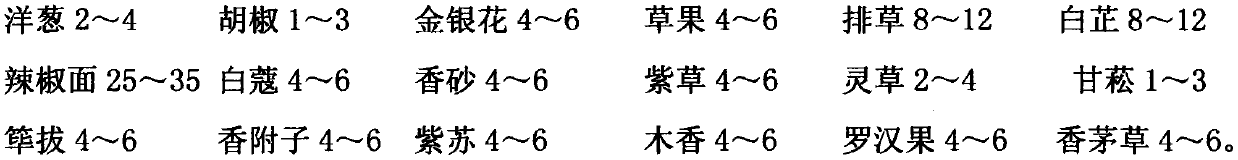

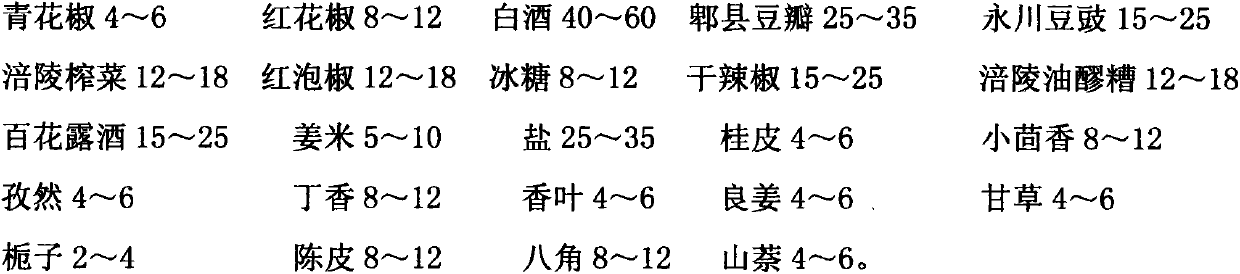

[0019] 3. Put 5g of green Zanthoxylum bungeanum and 10g of red Zanthoxylum bungeanum in 50g of white wine and soak for 8 hours, then add the green Zanthoxylum bungeanum, red Zanthoxylum bungeanum, and white wine together with 30g of Pixian Douban, 20g of Yongchuan Douchi, 15g of Fuling mustard, 15g of red pickled pepper, 10g of Rock sugar, 20g dried chilies, 15g Fuling fermented glutinous rice, 20g Baihualu wine, 8g ginger rice, 30g salt, 5g cinnamon, 10 cumin, 5g cumin, 10g cloves, 5g fragrant leaves, 5g galangal, 5g licorice, 3g gardenia , 10g tang...

Embodiment 2

[0021] The preparation technology of this chafing dish bottom material comprises the following steps:

[0022] 1. Put 90g of butter, 100g of rapeseed oil, 90g of soybean oil, 90g of peanut oil, and 70g of hazelnut oil into a pot and heat to 60°C to obtain the first mixture.

[0023] 2. Add 40 g of glutinous rice cake pepper to the first mixture, stir evenly to obtain the second mixture, and heat the second mixture to 95°C.

[0024] 3. Soak 4g of green peppercorns and 8g of red peppercorns in 40g of white wine for 5 hours, then add the green peppercorns, red peppercorns, and liquor together with 25g of Pixian Douban, 15g of Yongchuan Douchi, 12g of Fuling mustard, 12g of red pickled peppers, 8g Rock sugar, 15g dried chilies, 12g Fuling fermented glutinous rice, 15g Baihualu wine, 5g ginger rice, 25g salt, 4g cinnamon, 8g cumin, 4g cumin, 8g cloves, 4g fragrant leaves, 4g galangal, 4g licorice, 2g gardenia , 8g tangerine peel, 8g star anise, 4g kaempferen, 2g onion, 1g pepper, ...

Embodiment 3

[0026] The preparation technology of this chafing dish bottom material comprises the following steps:

[0027] 1. Put 100g of butter, 110g of rapeseed oil, 140g of soybean oil, 110g of peanut oil, and 90g of hazelnut oil into a pot and heat to 80°C to obtain the first mixture.

[0028] 2. Add 50 g of glutinous rice cake pepper into the first mixture, stir evenly to obtain the second mixture, and heat the second mixture to 110°C.

[0029] 3. Put 6g of green peppercorns and 12g of red peppercorns into 60g of white wine and soak for 10 hours, then put the green peppercorns, red peppercorns, and liquor together with 35g of Pixian Douban, 25g of Yongchuan Douchi, 18g of Fuling mustard, 18g of red pickled peppers, 12g Rock sugar, 25g dried chilies, 18g Fuling fermented glutinous rice, 25g Baihualu wine, 10g ginger rice, 35g salt, 6g cinnamon, 12 cumin, 6g cumin, 12g cloves, 6g fragrant leaves, 6g galangal, 6g licorice, 4g gardenia , 12g tangerine peel, 12g star anise, 6g kaempferen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com