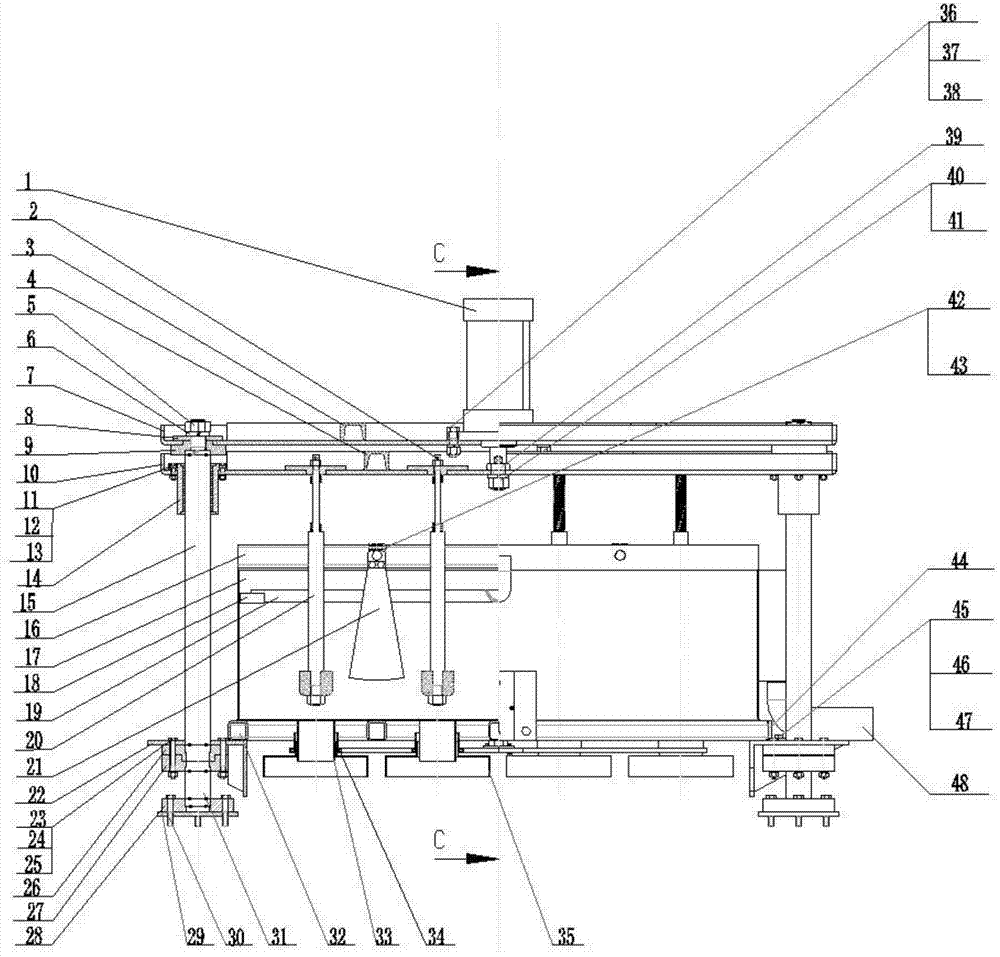

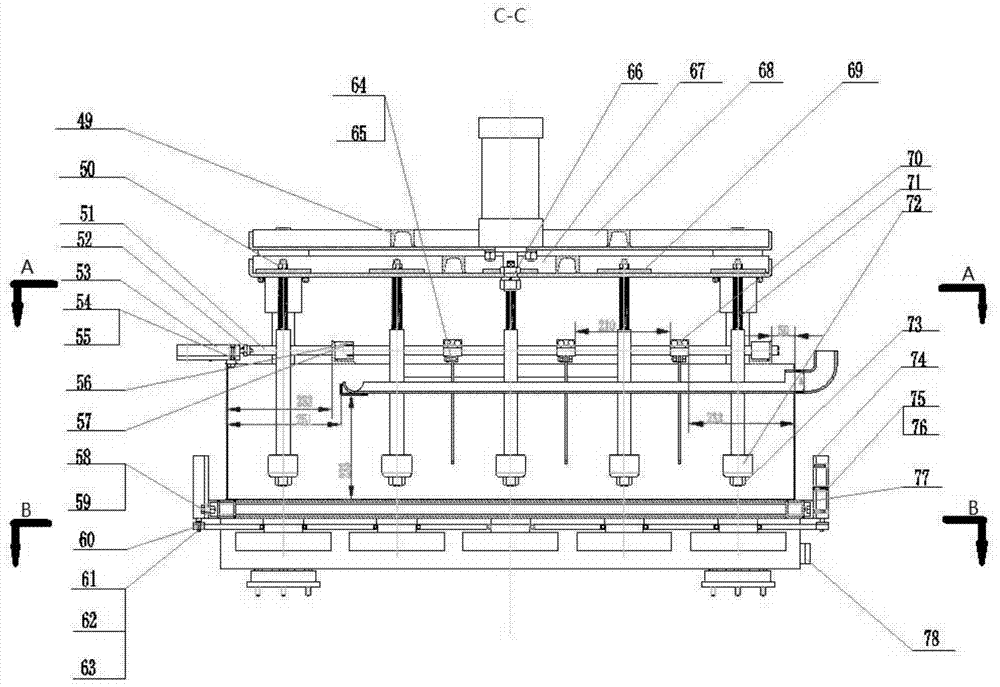

Round cake type nori dehydrating, blanking and forming equipment and forming method

A technology of round cake seaweed and forming equipment, which is applied in the field of food processing, can solve the problems of uneven distribution of material and liquid, low efficiency of cake making, and only thin cakes can be produced, so as to achieve simple and reasonable mechanism setting, saving device cost and occupied space , Improve the efficiency of cake making

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

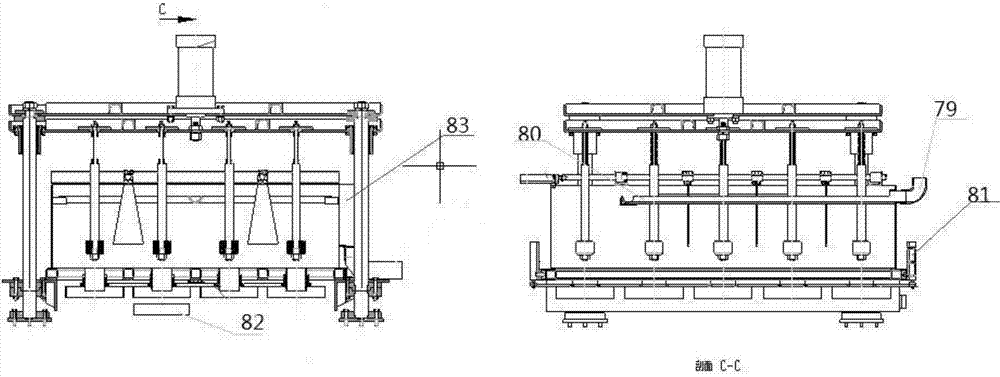

[0062] A kind of round cake laver dehydration blanking forming method, based on the above-mentioned round cake laver dehydration blanking forming equipment, specifically implement according to the following steps:

[0063] Step 1, the mixed seaweed feed liquid is transported to the lateral section 80 of the drainage pipe through the feed elbow 79, and the lateral section 80 of the drainage pipe is a groove-shaped channel, and its function is to guide the feed liquid into the feed tank evenly; After the section 80 is filled, the feed liquid will flow into the chute evenly and overflow, so that it is ensured that the feed liquid will not accumulate somewhere in the chute 17.

[0064] Step 2, when the feed liquid in the feed tank 17 reaches the height of the stirring blade 21, start stirring to push the cylinder 53, so that it drives the stirring blade 21 in the stirring device to fully stir the feed liquid in the feed tank. Specifically, the stirring shaft 51 is connected with t...

Embodiment 2

[0070] A kind of round cake laver dehydration blanking forming method of the present invention, based on above-mentioned round cake laver dehydration blanking forming equipment, specifically implement according to the following steps:

[0071] Step 1, the mixed seaweed feed liquid is transported to the lateral section 80 of the drainage pipe through the feed elbow 79, and the lateral section 80 of the drainage pipe is a groove-shaped channel, and its function is to guide the feed liquid into the feed tank evenly; After the section 80 is filled, the feed liquid will flow into the chute evenly and overflow, so that it is ensured that the feed liquid will not accumulate somewhere in the chute 17.

[0072] Step 2, when the feed liquid in the feed tank 17 reaches the height of the stirring blade 21, start stirring to push the cylinder 53, so that it drives the stirring blade 21 in the stirring device to fully stir the feed liquid in the feed tank. Specifically, the stirring shaft 5...

Embodiment 3

[0078] A kind of round cake laver dehydration blanking forming method of the present invention, based on above-mentioned round cake laver dehydration blanking forming equipment, specifically implement according to the following steps:

[0079] Step 1, the mixed seaweed feed liquid is transported to the lateral section 80 of the drainage pipe through the feed elbow 79, and the lateral section 80 of the drainage pipe is a groove-shaped channel, and its function is to guide the feed liquid into the feed tank evenly; After the section 80 is filled, the feed liquid will flow into the chute evenly and overflow, so that it is ensured that the feed liquid will not accumulate somewhere in the chute 17.

[0080] Step 2, when the feed liquid in the feed tank 17 reaches the height of the stirring blade 21, start stirring to push the cylinder 53, so that it drives the stirring blade 21 in the stirring device to fully stir the feed liquid in the feed tank. Specifically, the stirring shaft 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com