Oil-control shampoo and preparation method thereof

An oil washing and sodium cocamido propionate technology, applied in the field of shampoo, can solve the problems of difficult to wash hair, excessive accumulation of scalp, failure to achieve oil control, etc., and achieves good oil control effect and good skin-friendly ability. , good cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

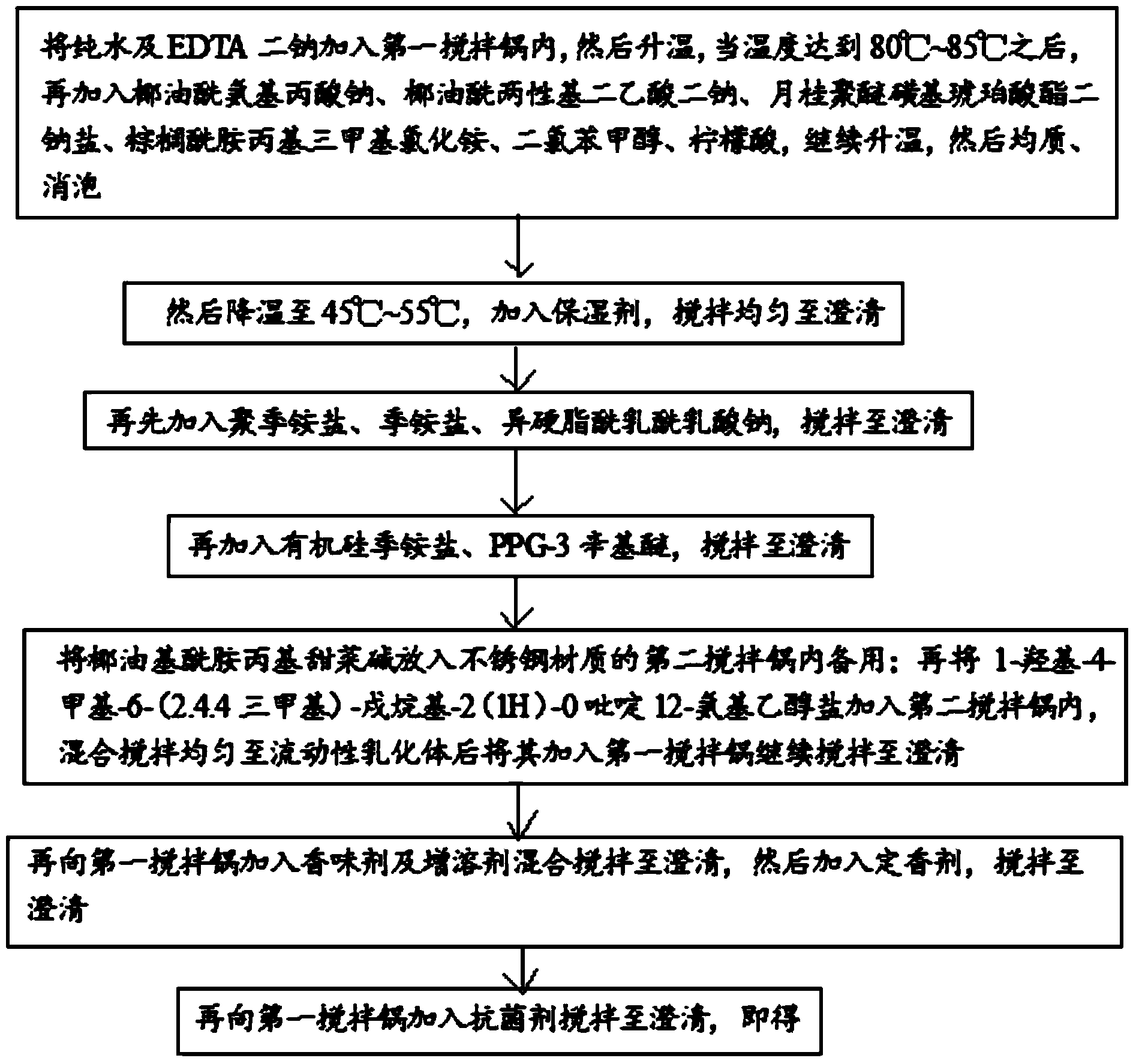

[0096] see figure 1 , the preparation method of the present invention comprises the following steps:

[0097] 1. Add the pure water and disodium EDTA in group A into the stirring pot, and then raise the temperature. When the temperature reaches 80°C-85°C, add the remaining components in group A, and continue to heat up to above 80°C-85°C. Homogenize for 5 minutes and defoam. In this step, raising the temperature to above 80° C. to 85° C. can kill bacteria on the surface of the raw materials, and evenly dissolve the raw materials of all components.

[0098] 2. Cool down to 45°C-55°C, add the components of Group B, stir evenly until clear;

[0099] 3. Then add the components of Group C and stir until clear;

[0100] 4. Then add the components of Group D and stir until clear;

[0101] 5. Mix and stir the flavoring agent and solubilizing agent of Group E until clear, then add the fixative, stir until clear, then add it into the stirring pot, and continue stirring until clear. ...

Embodiment 1

[0107] The oil control shampoo in the present embodiment is made from the following raw materials in weight percentage:

[0108] Pure water 37.20%;

[0109] Disodium EDTA 0.10%;

[0110] Sodium Cocoamidopropionate 15%;

[0111] Disodium Cocoamphodiacetate 5%;

[0112] Disodium laureth sulfosuccinate 25%;

[0113] Palmimidopropyltrimethylammonium Chloride 4%;

[0114] Dichlorobenzyl alcohol 0.2%;

[0115] Citric acid 0.3%;

[0116] Moisturizer 3%; (among them, glycerin 2%, trimethylglycine 1%)

[0117] Polyquaternium 2%;

[0118] Quaternary ammonium salt 2%;

[0119] Sodium isostearyl lactylate 1%;

[0120] Silicone quaternary ammonium salt 2%;

[0121] PPG-3 octyl ether 0.2%;

[0122] Cocamidopropyl Betaine 1%

[0123] 1-Hydroxy-4-methyl-6-(2.4.4 trimethyl)-pentyl-2(1H)-0 pyridine 12-aminoethanol salt 0.5%

[0124] Fragrance agent 0.2%; (in the present embodiment, fragrance agent adopts Chanel No. 5 perfume)

[0125] Solubilizer 0.9%; (in the present embodiment, ...

Embodiment 2

[0139] The oil control shampoo in the present embodiment is made from the following raw materials in weight percentage:

[0140] Pure water 35%;

[0141] Disodium EDTA 0.15%;

[0142] Sodium Cocoamidopropionate 12%;

[0143] Disodium Cocoamphodiacetate 7%;

[0144] Disodium laureth sulfosuccinate 28%;

[0145] Palmimidopropyltrimethylammonium Chloride 6%;

[0146] Dichlorobenzyl alcohol 0.15%;

[0147] Citric acid 0.3%;

[0148] Moisturizer 2.3%; (among them, glycerin 2%, trimethylglycine 0.3%)

[0149] Polyquaternium 1.6%;

[0150] 1.5% quaternary ammonium salt;

[0151] Sodium isostearyl lactylate 0.8%;

[0152] Silicone quaternary ammonium salt 2%;

[0153] PPG-3 octyl ether 0.22%;

[0154] Cocamidopropyl Betaine 0.8%;

[0155] 1-Hydroxy-4-methyl-6-(2.4.4 trimethyl)-pentyl-2(1H)-0 pyridine 12-aminoethanol salt 0.4%

[0156] Fragrance agent 0.3%; (in the present embodiment, fragrance agent adopts Chanel No. 5 perfume)

[0157] Solubilizer 1.2%; (in the present ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com