Oil-control repairing concealer and production process thereof

A production process and concealer technology, which is applied in the field of oil control repair concealer, oil control repair concealer production process, can solve the problems of oil accumulation, pore clogging, etc., and achieve the effect of reducing content and strengthening oil control ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0120] Embodiment 1: a kind of oil-control repairing concealer, its preparation method is as follows:

[0121] S1: Mix silica dimethyl silylate and squalane, and stir at 20±5°C for 25 minutes to obtain the first mixed phase;

[0122] S2: Mix the thickener, petrolatum and jojoba seed oil and heat it to 95°C to melt it, keep stirring and lower the temperature to 60°C, and add the first mixed phase obtained in step 1 to obtain the second Two mixed phases;

[0123] S3: At 60°C, add antioxidants, aluminum chlorohydrate, fillers and preservatives to the second mixed phase obtained in step S2, and stir thoroughly for 5 minutes to obtain the third mixed phase;

[0124] S4: Add the colorant to the third mixed phase obtained in step S3, and homogenize for 7 minutes to obtain a colored mixed phase;

[0125] S5: Lower the temperature of the colored mixed phase obtained in step S4 to 35°C while keeping stirring to obtain the cooled colored mixed phase, and take a sample of the cooled col...

Embodiment 2-3

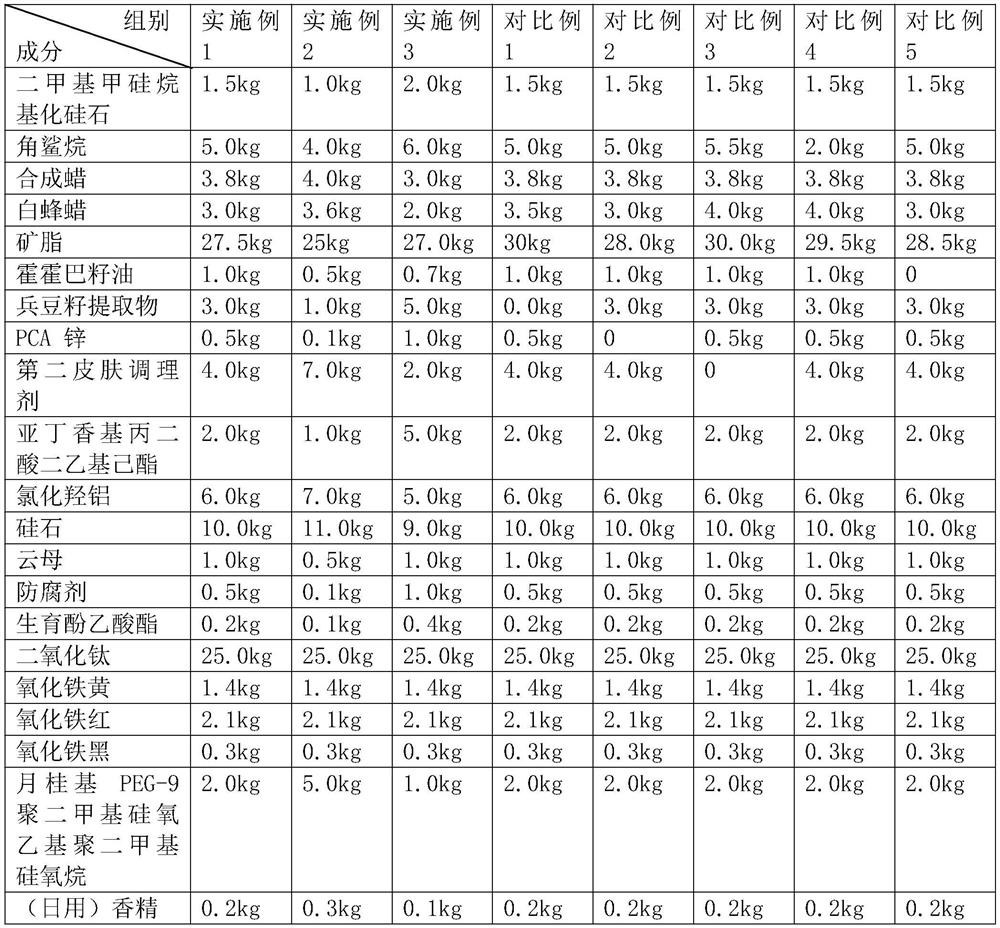

[0140] Embodiment 2-3: An oil-controlling and repairing concealer, the difference from Embodiment 1 is that the amount of some materials added varies.

Embodiment 4-12

[0150] Embodiment 4-12, an oil control concealer repair cream, differs from Embodiment 1 in that the specific ingredients in the second skin conditioning agent are different. The specific components of the plant extracts in Examples 1 and 4-12 are shown in Table 3.

[0151] Table 3: List of Secondary Skin Conditioning Agent Ingredients in Example 1 and Examples 4-12

[0152]

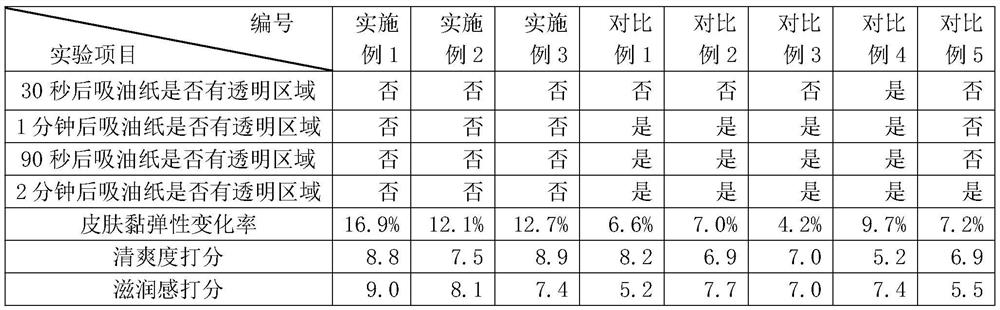

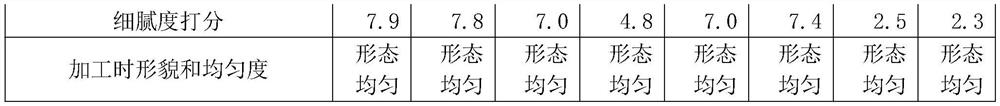

[0153] Experiment 1, Experiment 2, Experiment 3 and Experiment 4 were carried out on Examples 1 and 4-12, and the experimental results are shown in Table 4 respectively.

[0154] Table 4: Results of skin oil control ability, skin repair ability, skin feeling score and irritation test of Example 1 and Examples 4-12

[0155]

[0156]

[0157] In the above experimental results, Example 1, Example 4, and Example 5 all have good water retention and oil control repairing effects, reduce the oil content on the skin surface, and improve the viscoelasticity of the skin. And Example 1, Example 4 and Exa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com