Rotor cyclone two-stage serial mineral flotation defoaming device

A technology of mineral flotation and cyclone separation device, which is applied in the direction of flotation, the feeding/discharging device of the settling tank, and the separation of dispersed particles, which can solve the problems of environmental pollution and large water consumption, and achieve simple and reliable separation, reduce Emissions, chemical and water consumption savings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

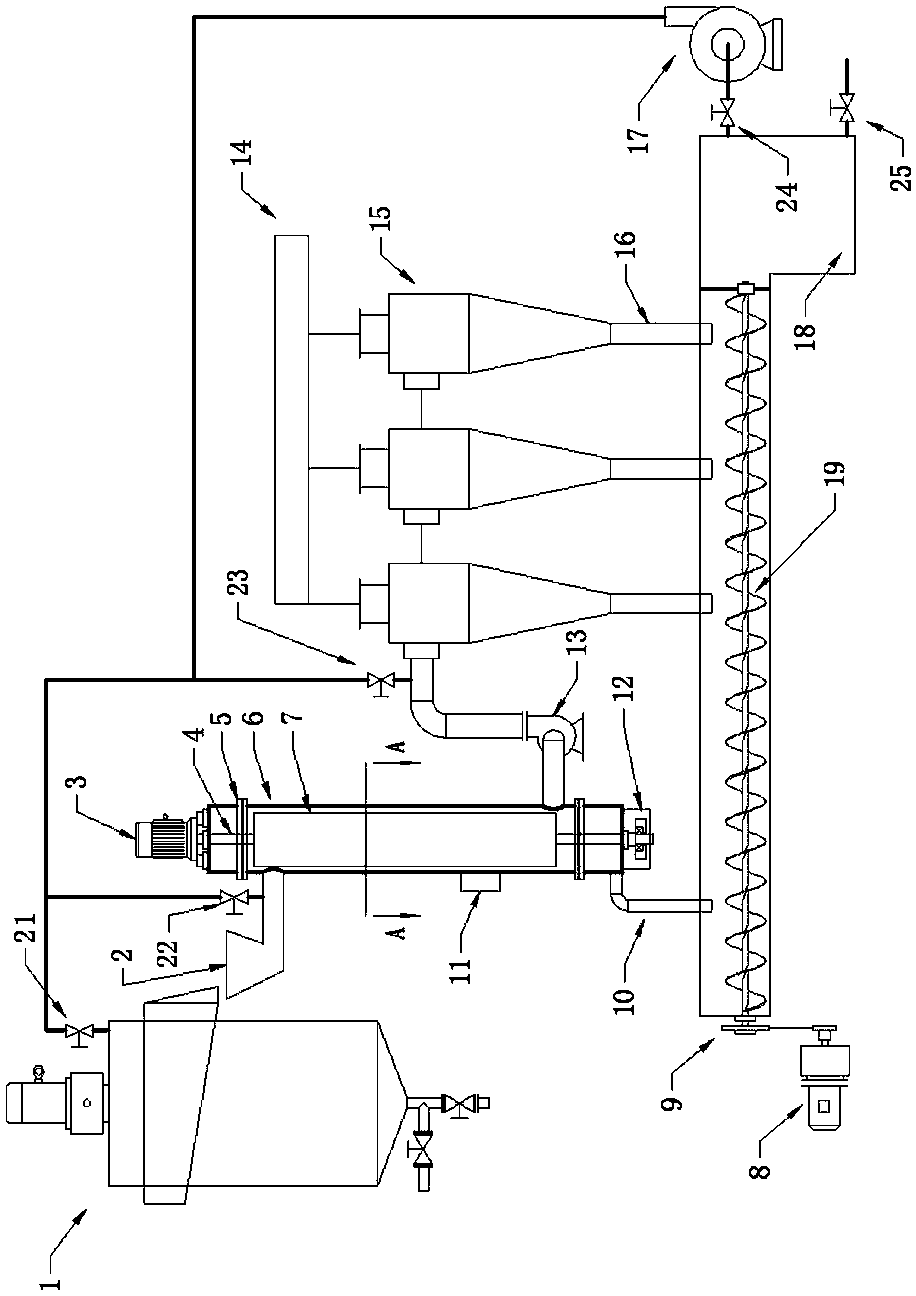

[0028] Now in conjunction with accompanying drawing, the present invention is described in further detail.

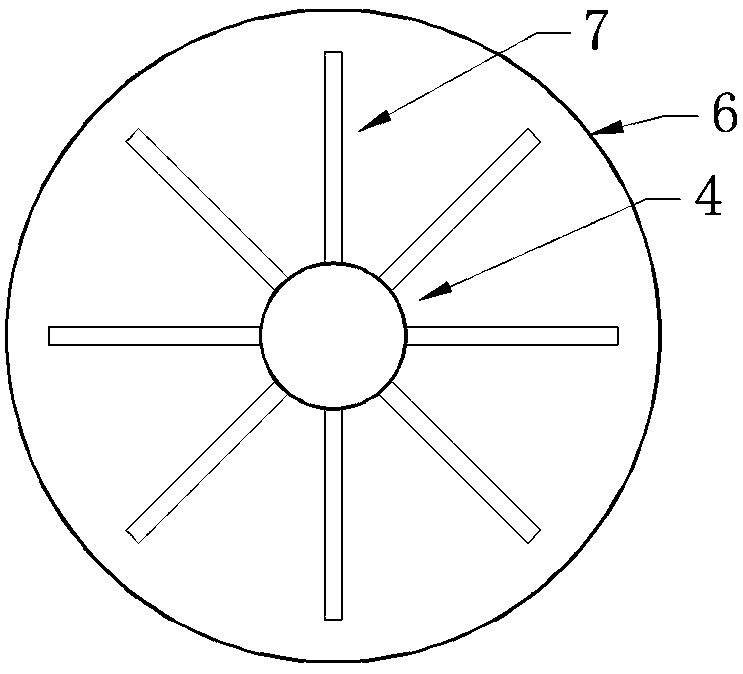

[0029] Such as figure 1 and figure 2 The shown rotor cyclone two-stage series mineral flotation defoaming device includes a flotation machine 1, a foam feeding hopper 2, a rotor, an exhaust fan 13, a cyclone separation device 15, an exhaust pipe 14, a screw conveyor 19 and a settling tank 18 , the rotor is located in the cylinder 6 and is composed of a rotating shaft 4 and blades 7. The cylinder 6 has a discharge pipe 10 connected to a screw conveyor 19; the flotation machine 1 is connected to the foam hopper 2, and the foam hopper 2 is connected to the exhaust fan through the cylinder 13. The exhaust fan 13 is connected to the cyclone separation device 15, the top of the cyclone separation device 15 is connected to the exhaust pipe 14, the bottom is connected to the screw conveyor 19 through the discharge pipe 16, and the discharge port of the screw conveyor 19 is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com