Numerical control bagged spring machine

A pocket spring and coil spring technology, applied in the field of CNC pocket spring machines, can solve the problems of fixed cylinder stroke, easy damage to components, and high energy consumption, and achieve reliable mechanism movement, reduced production costs, and controllable stroke length. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

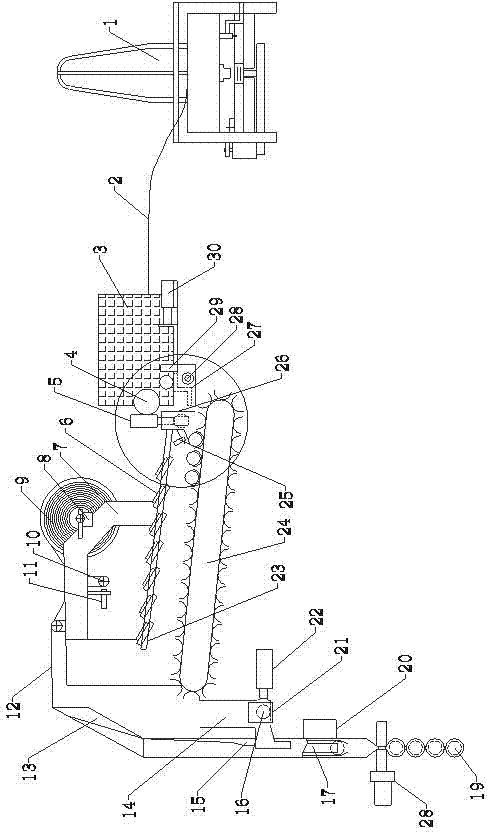

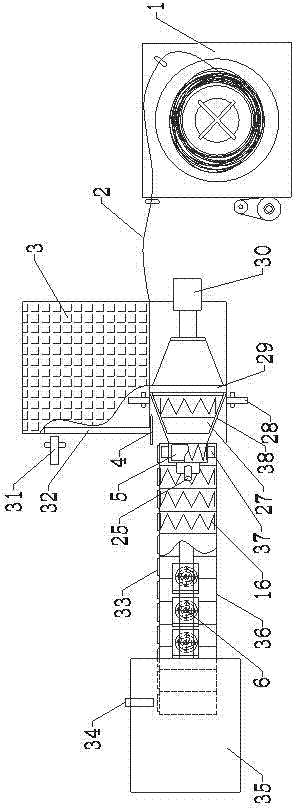

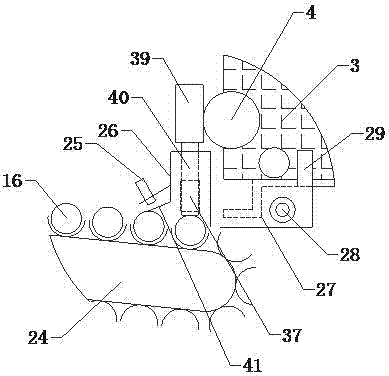

[0029] As shown in the figure, the present invention includes a feeding mechanism 1, a coil spring mechanism 3, a chain box transmission mechanism 24, a cloth rolling mechanism and a welding assembly mechanism 35. The left end front side of the coil spring mechanism 3 is provided with a compression heating mechanism, The compression heating mechanism includes a slope guide groove 38, an L-shaped push plate 27, a pressing mechanism 5 and a heating electrode 37. The side of the chain box 36 of the chain box transmission mechanism 24 is provided with a magnetic block 33. There is a third sensor 34 corresponding to it. This structure effectively monitors the movement of the chain box 36. Every time a frame is moved, the control unit can collect information through the third sensor 34, thereby controlling other devices to run synchronously; The welding assem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com