Automatic Vertical Forming Machine

A molding machine and automatic technology, applied in the field of automatic vertical molding machines, can solve the problems of tantalum wire straightness and verticality can not meet process requirements, uneven pressing density, large powder weight deviation, etc., and achieve easy weight and size adjustment and control. , good use value and economic value, good quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

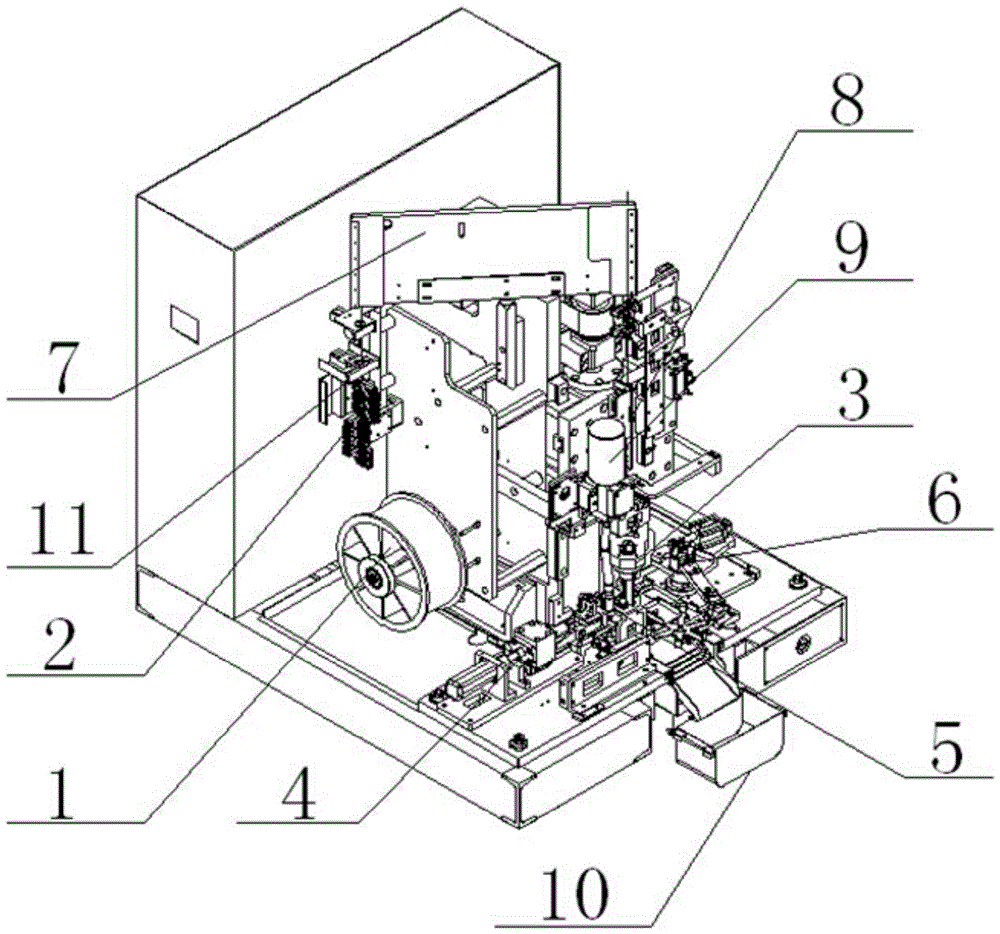

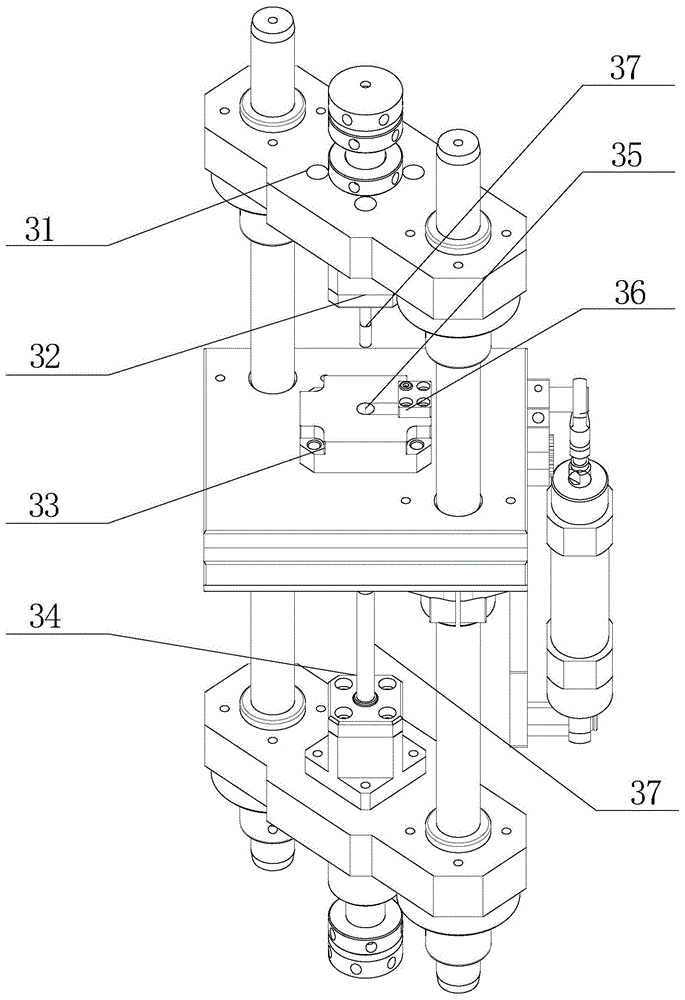

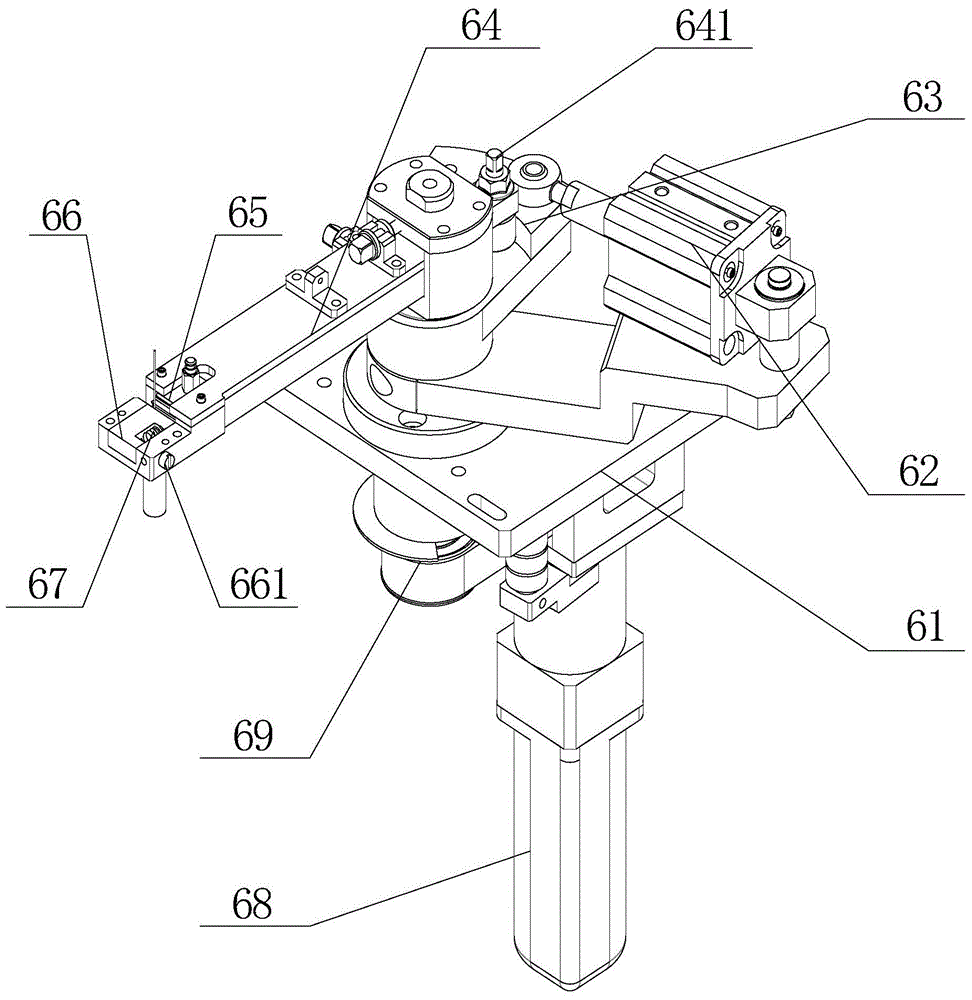

[0019] Embodiment of the present invention: an automatic vertical forming machine, as attached Figure 1-4 As shown, after the tantalum wire is drawn out from the coiled tantalum wire reel 1 set on the left side of the vertical mounting frame above the frame, it passes through the primary straightening mechanism 2 set above it, and then passes through the primary straightening mechanism 2 In the upper tantalum wire supply mechanism 11, the tantalum wire supply mechanism 11 enters the mold cavity 35 of the forming mold 3 provided at the middle position of the horizontal mounting plate in the middle of the frame, and the powder shaking mechanism 4 on the left side of the horizontal mounting plate The tantalum powder will be sent from the shaker box 5 into the mold cavity 35, and the tantalum powder inserted with the tantalum wire will be pressed and formed by the molding die 3, and then the tantalum wire will be cut off by the cutting and flattening mechanism 6 on the right side ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com