Multifunctional flaw detection vehicle for highland railway steel rail

A detection vehicle and multi-functional technology, applied in the field of rail flaw detection and multi-functional detection flaw detection vehicle, can solve the problems of noise and vibration detection equipment having a great influence, the speed structure cannot meet the requirements, and the detection results are not accurate enough to achieve good work. and living environment, the structure is reasonable and practical, and the effect of meeting the testing requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

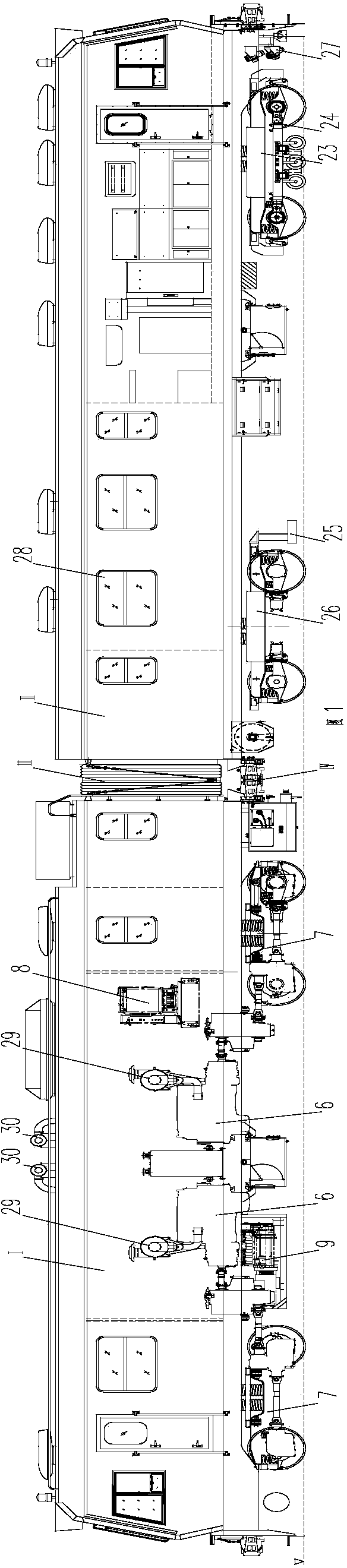

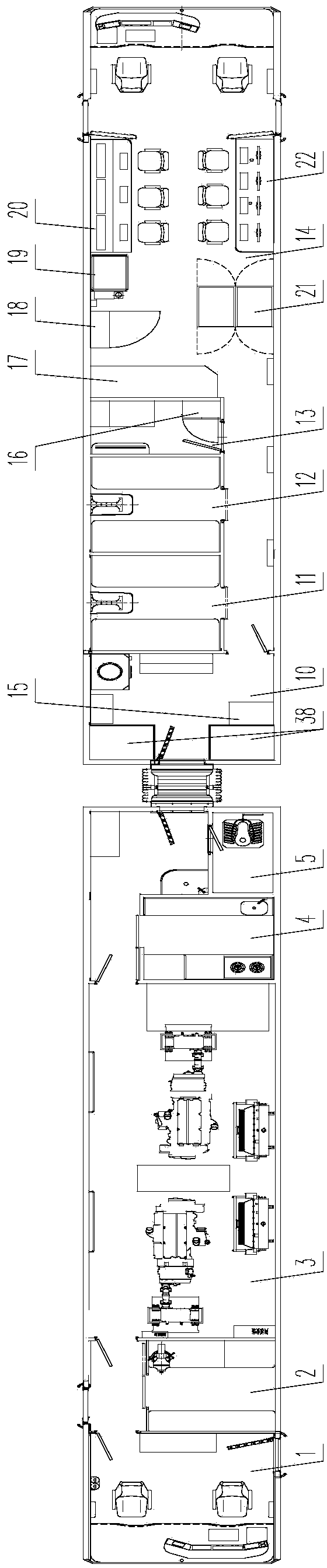

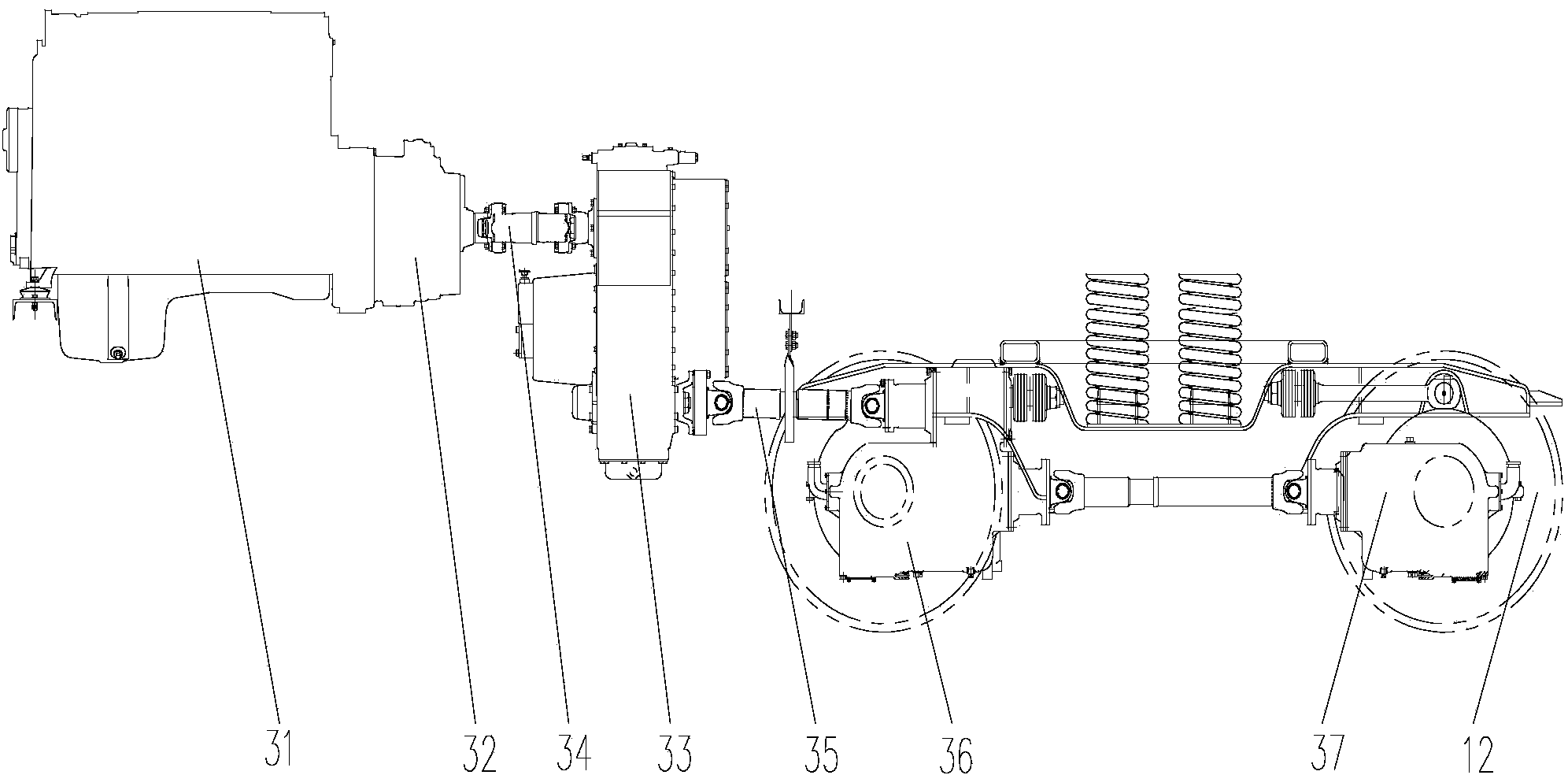

[0021] Attached below Figure 1-3 An embodiment of the present invention is described.

[0022] A multifunctional flaw detection vehicle for plateau railway rails. It has a tractor I and a detection vehicle II. The tractor I and the detection vehicle II are connected by a bellows windshield III and a coupler IV. The tractor I is equipped with a driver's cab 1. Maintenance room 2, machine room 3, kitchen room 4 and bathroom 5. The inspection vehicle II is equipped with a coupling medium room 10, a sleeping area 11, a wheel temperature control room 13 and a detection work area 14. The machine There are two sets of engines with a total power of 806kW in room 3, which meet the power plant 6 required for the detection of altitude ≤5100m. The two sets of power plant 6 are installed separately and drive two front and rear bogies 7 and bogies 7 respectively. The main components are made of materials with good low-temperature performance, and the damping pad is made of rubber damping pad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com