Track height irregularity prediction system and method based on axle box vibration acceleration

A vibration acceleration and prediction system technology, which is applied in the direction of railway vehicle shape measuring device, railway car body parts, transportation and packaging, etc., can solve the problems of not being applicable to ordinary operating vehicles and poor engineering construction, so as to avoid operation and maintenance costs and ensure reliability High performance and good engineering implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

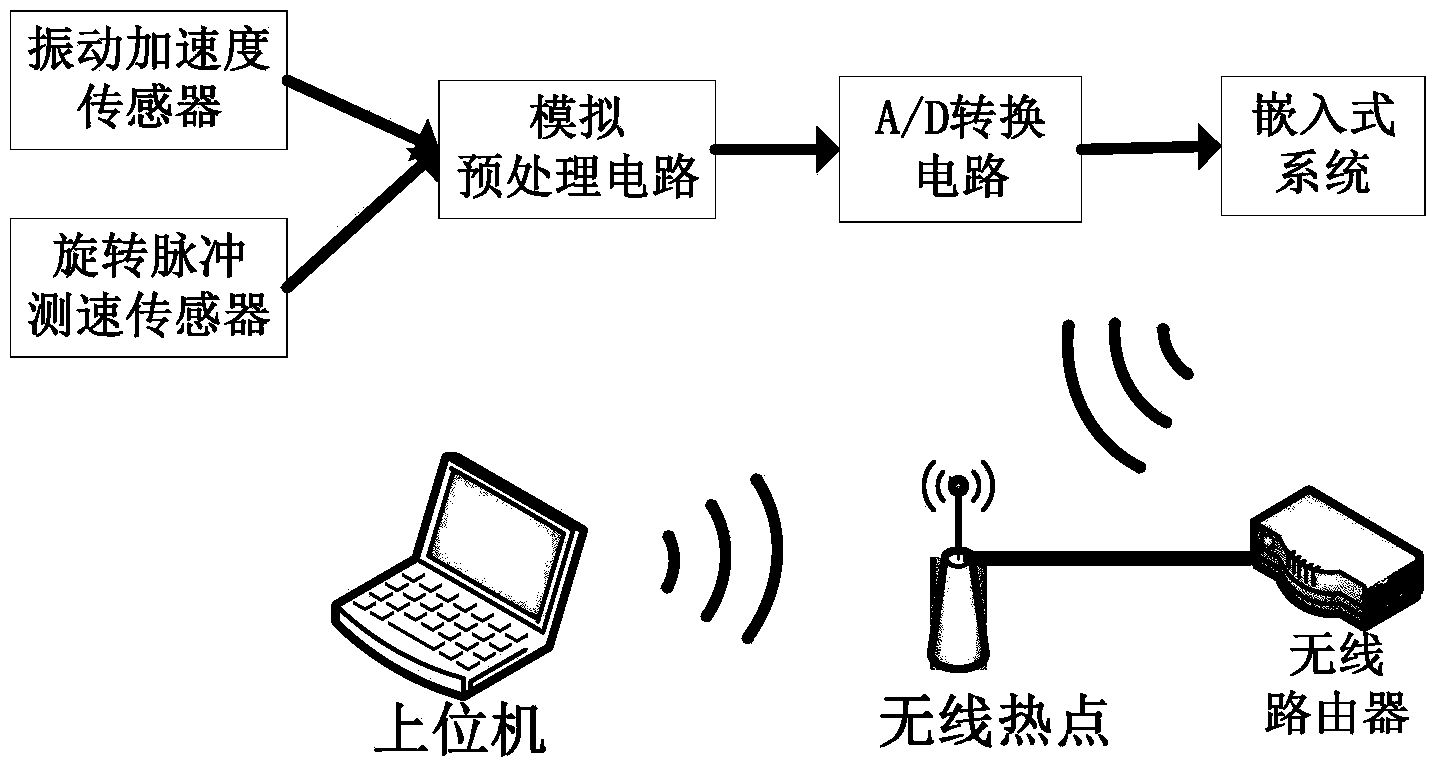

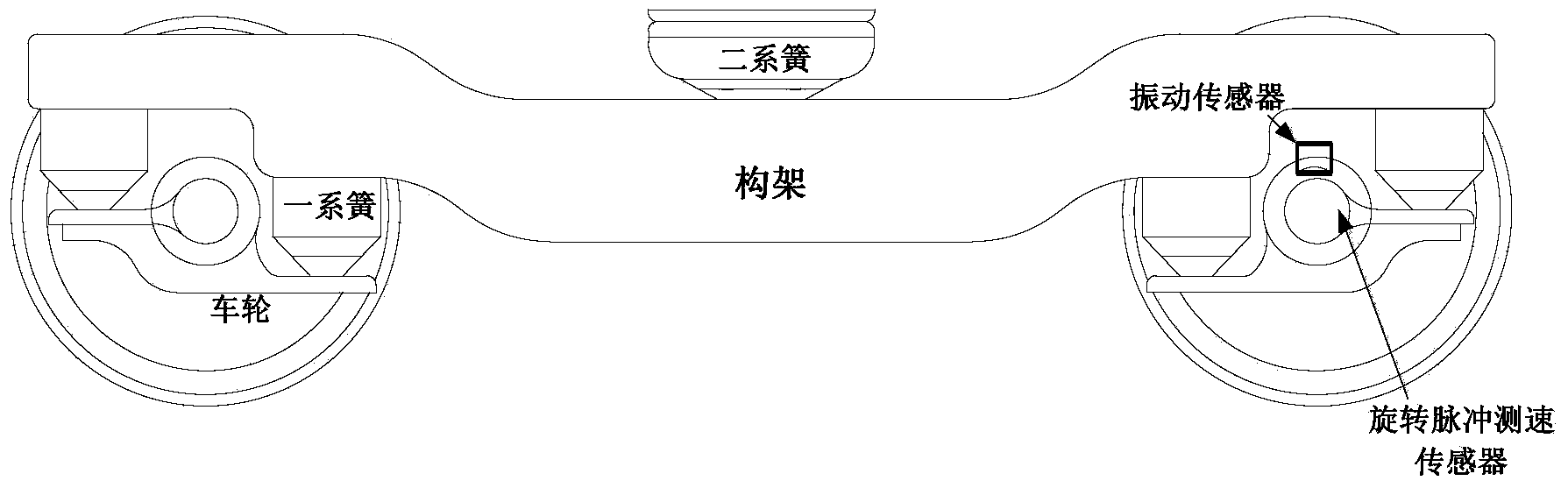

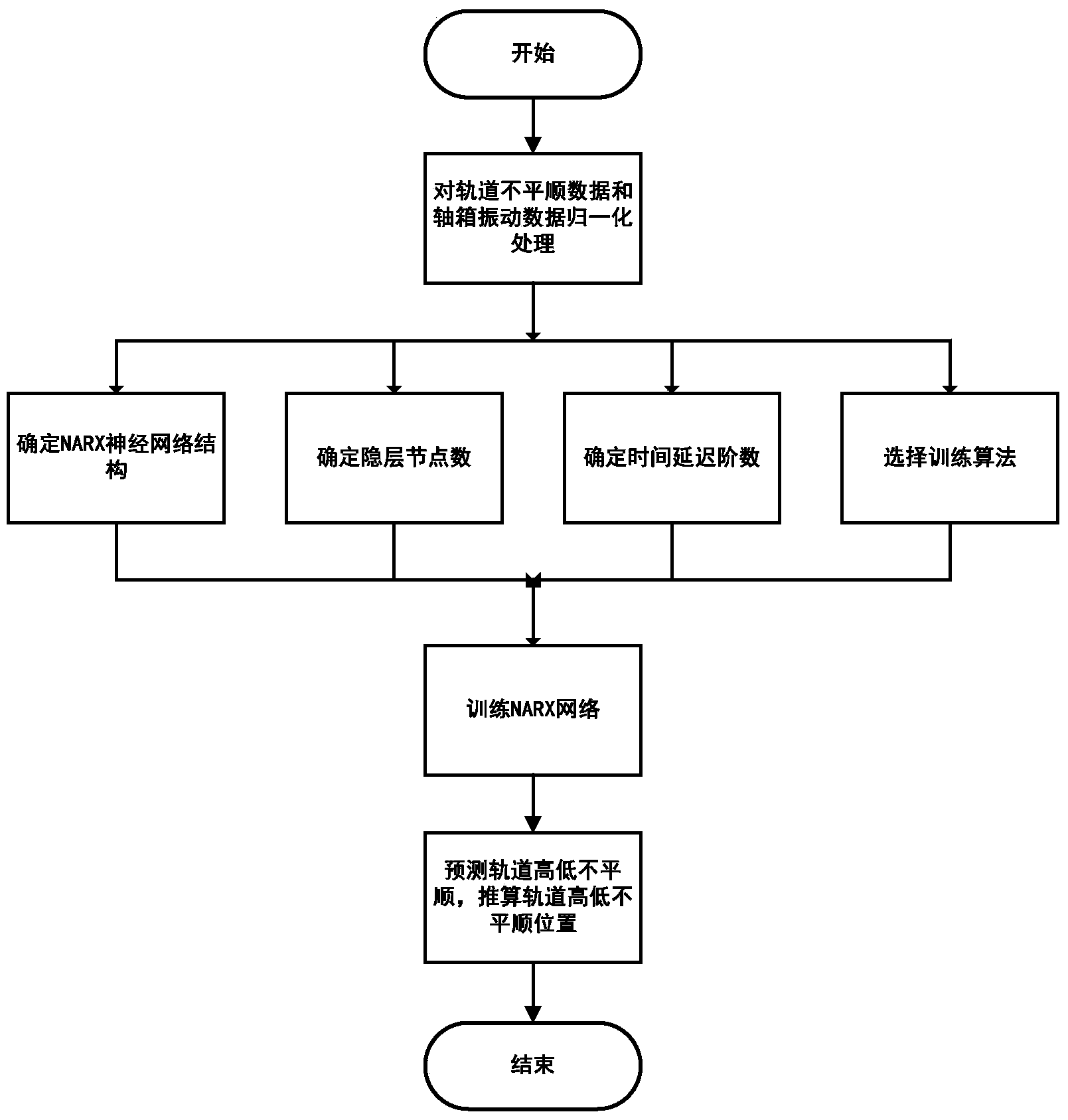

[0041] combine figure 1 , the track height irregularity prediction system based on the axlebox vibration acceleration of the present invention includes an axlebox vibration acceleration sensor, a rotation pulse speed sensor, an analog preprocessing circuit, an A / D conversion circuit, an embedded system, a wireless network routing, and a host computer; The axlebox vibration acceleration sensor is arranged on the axlebox of the running part of the train, the rotation pulse speed measuring sensor is arranged in the axle end cover of the train, and the output terminals of the axlebox vibration acceleration sensor and the rotation pulse speed measuring sensor are connected to the analog preprocessing circuit , the output end of the analog preprocessing circuit is connected to the embedded system through the A / D conversion circuit; the axle box vibration signal collected by the axle box vibration acceleration sensor and the vehicle speed signal collected by the rotation pulse speed m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com