Knitting method for ultrathin high-grade sports underwear knitted fabric

A knitted fabric, high-grade technology, applied in the field of clothing fabrics, can solve the problem of not being able to guarantee the lightness and high-end feeling of sports underwear fabrics, and achieve the effects of good moisture absorption and perspiration, comfortable wearing and broad market prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

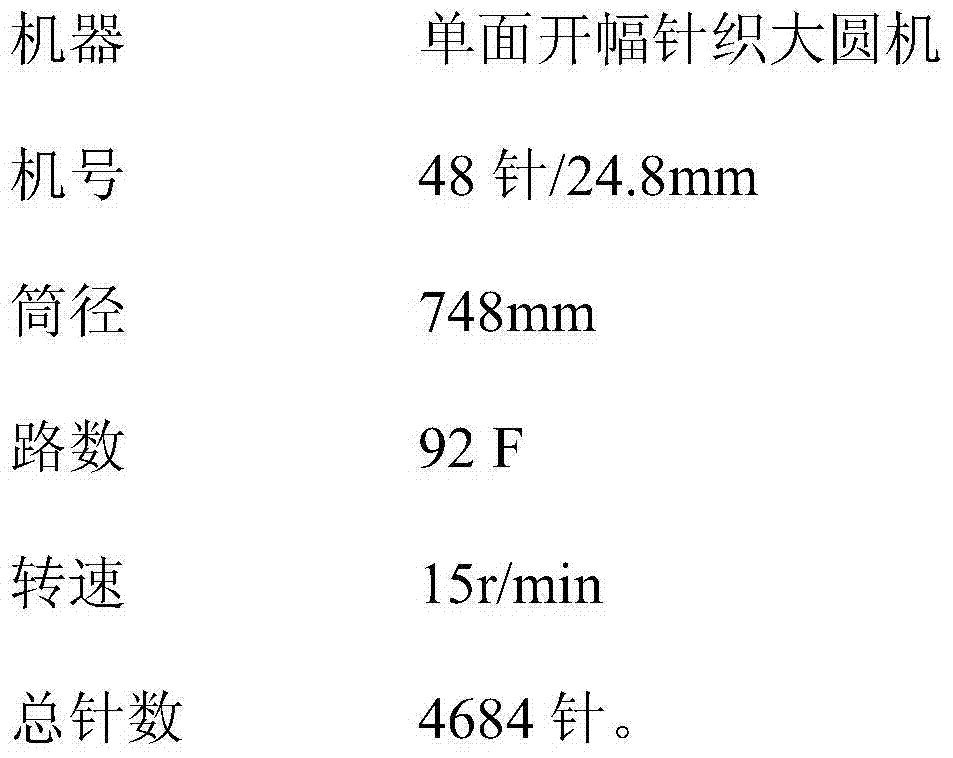

Embodiment 1

[0016] The knitting method of the ultra-thin and high-grade sports underwear knitted fabric of the present invention uses fine-denier polyester yarn as the veil and spandex yarn as the ground yarn, and weaves according to the following process:

[0017]

[0018] The mass ratio of fine denier polyester yarn to spandex yarn is 5:5. The linear density of fine denier polyester yarn is 3.2tex / 24f; the linear density of spandex yarn is 2.1tex.

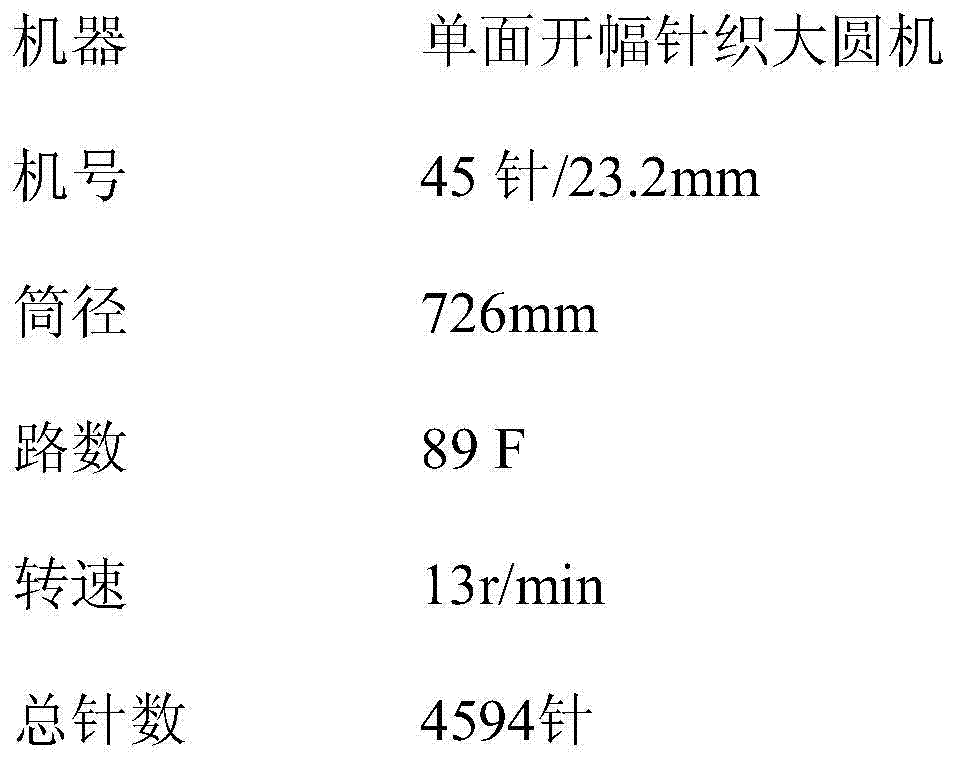

Embodiment 2

[0020] The knitting method of the ultra-thin and high-grade sports underwear knitted fabric of the present invention uses fine-denier polyester yarn as the veil and spandex yarn as the ground yarn, and weaves according to the following process:

[0021]

[0022] The mass ratio of fine denier polyester yarn to spandex yarn is 6:4. The linear density of fine denier polyester yarn is 3.5tex / 24f; the linear density of spandex yarn is 2.4tex.

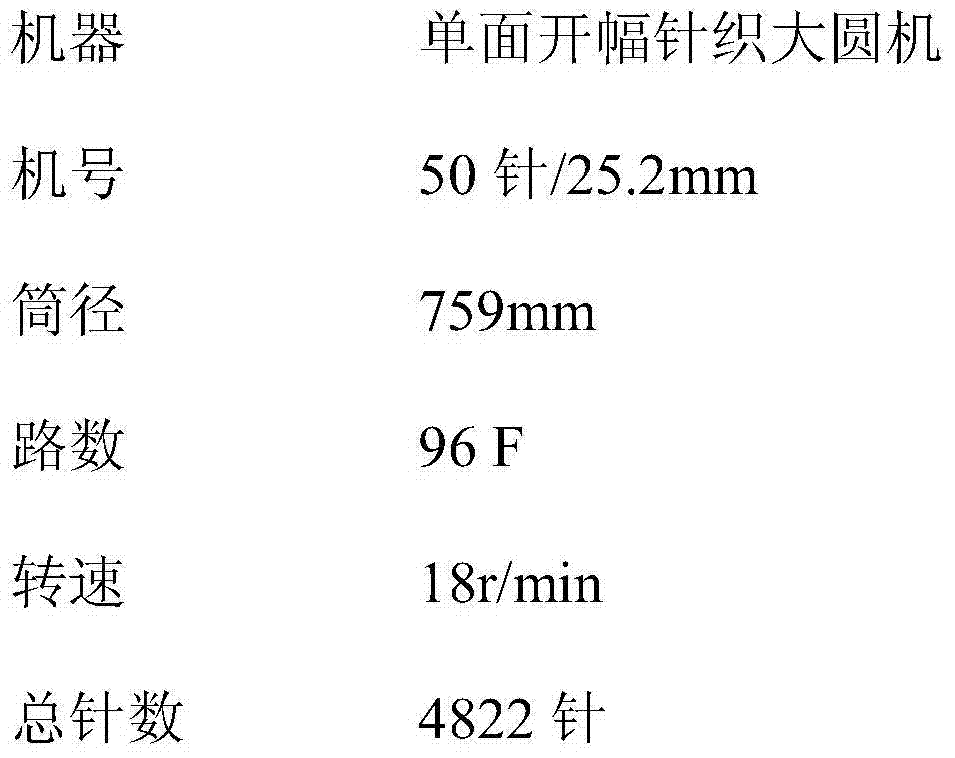

Embodiment 3

[0024] The knitting method of the ultra-thin and high-grade sports underwear knitted fabric of the present invention uses fine-denier polyester yarn as the veil and spandex yarn as the ground yarn, and weaves according to the following process:

[0025]

[0026] The mass ratio of fine denier polyester yarn to spandex yarn is 5.5:4.5. The linear density of fine denier polyester yarn is 3.4tex / 24f; the linear density of spandex yarn is 2.3tex.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com