Method for preventing surging of fans

A fan and combustion-supporting fan technology, applied in mechanical equipment, machine/engine, pump control, etc., can solve problems such as combustion-supporting fan surge, achieve the effects of protecting the fan, avoiding surge phenomenon, and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

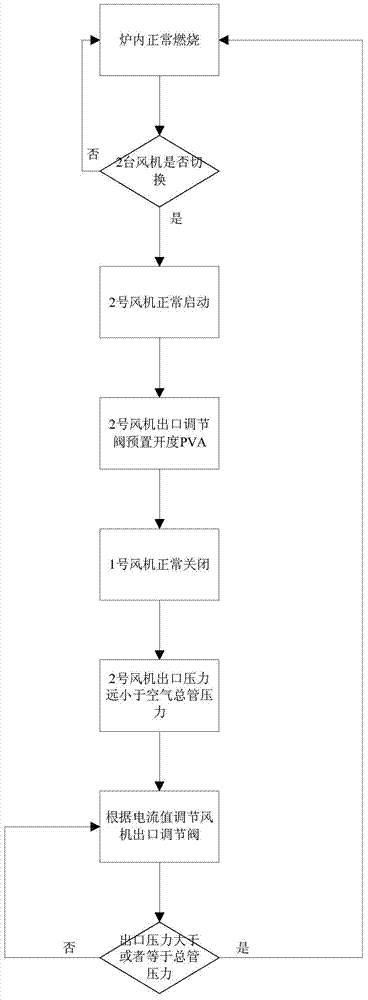

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0024] The rated current value of the two combustion-supporting blowers in this specific embodiment is 170 amperes.

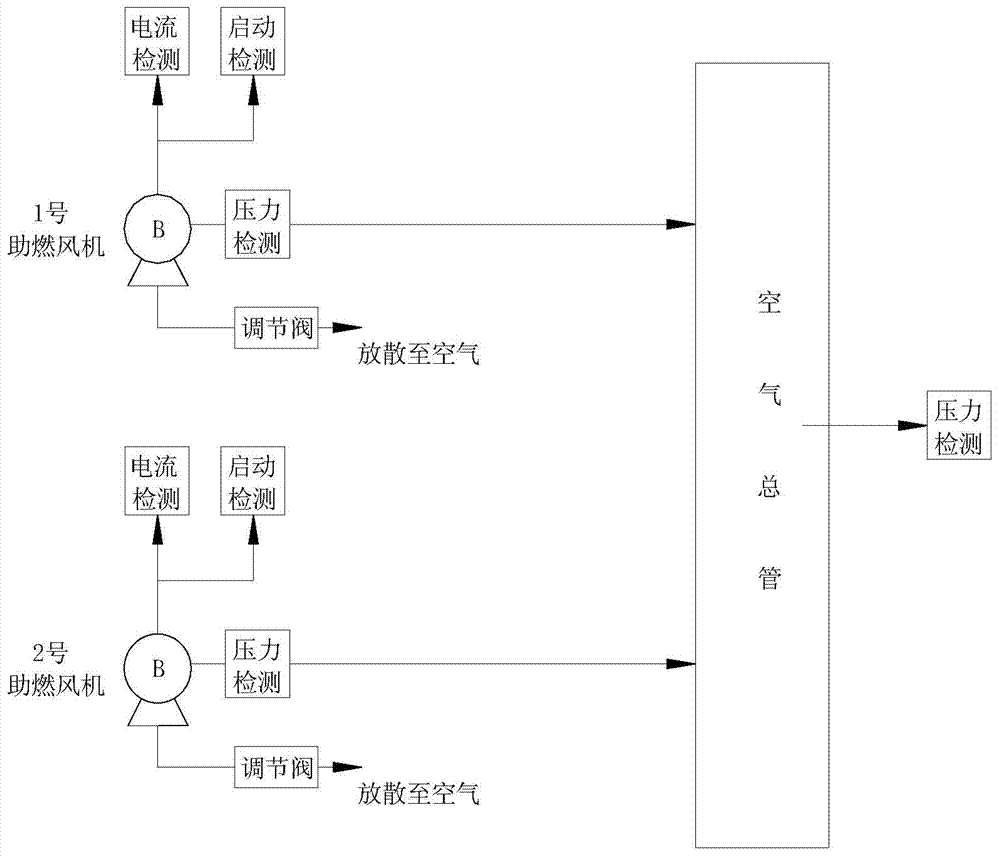

[0025] figure 1 Flowchart for on-site detection distribution. Compared with the prior art, the present invention only adds a regulating valve and a pressure detection device at the outlet of each combustion-supporting blower.

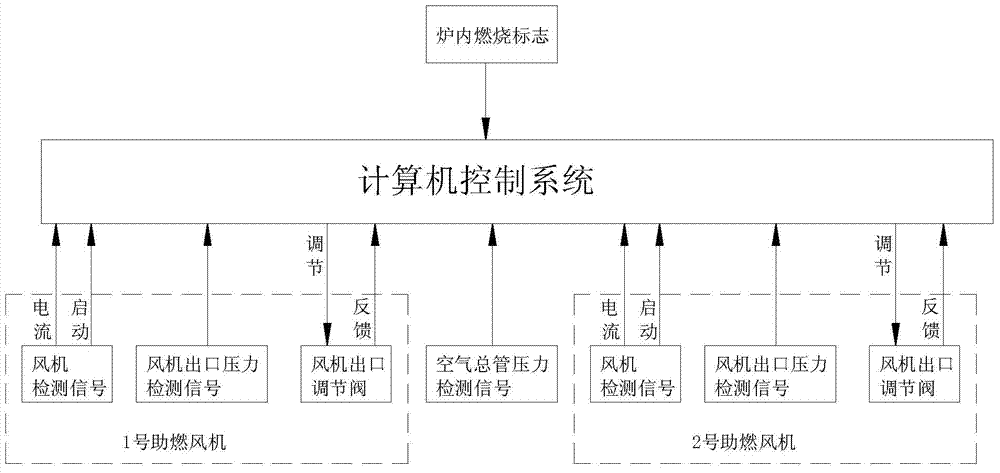

[0026] figure 2 It is the relationship diagram between each detection signal and the computer control system. Depend on figure 2 It can be seen that the collected starting signals, current detection signals, outlet pressure detection signals, air main pipe pressure detection signals and furnace combustion signs of the two combustion-supporting fans are all sent to the computer control system. The combustion mark in the furnace is a function set by the user of the high-temperature annular ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com