Internal tooth and external tooth symmetry degree detecting device

A detection device and a technology of symmetry, applied in the direction of measuring gears, etc., can solve the problems of not being able to meet the mass production of the production line, increase the processing cost of gearbox gears, and the cumbersome detection process, so as to achieve the integration of positioning and calibration and low processing cost , The detection process is fast and accurate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

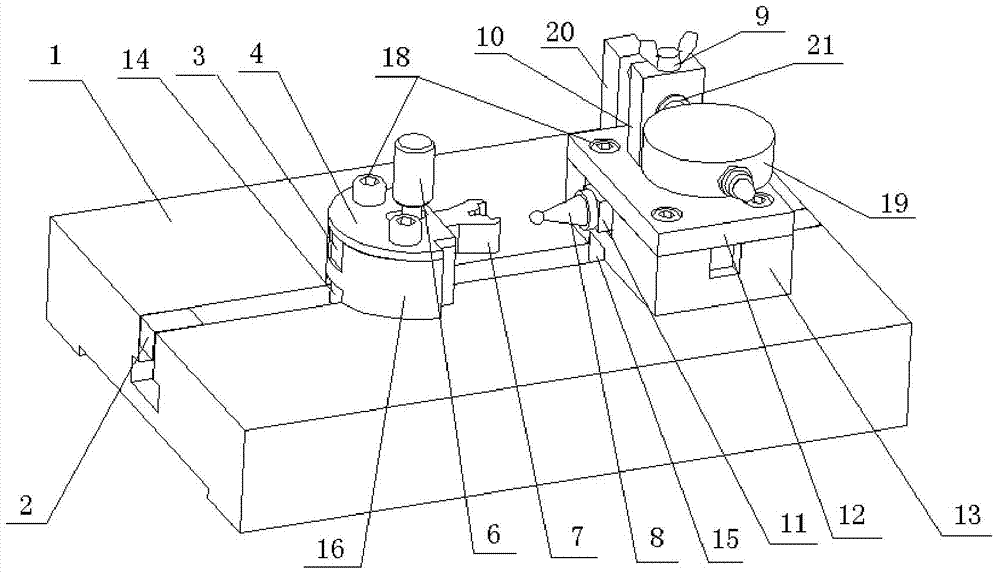

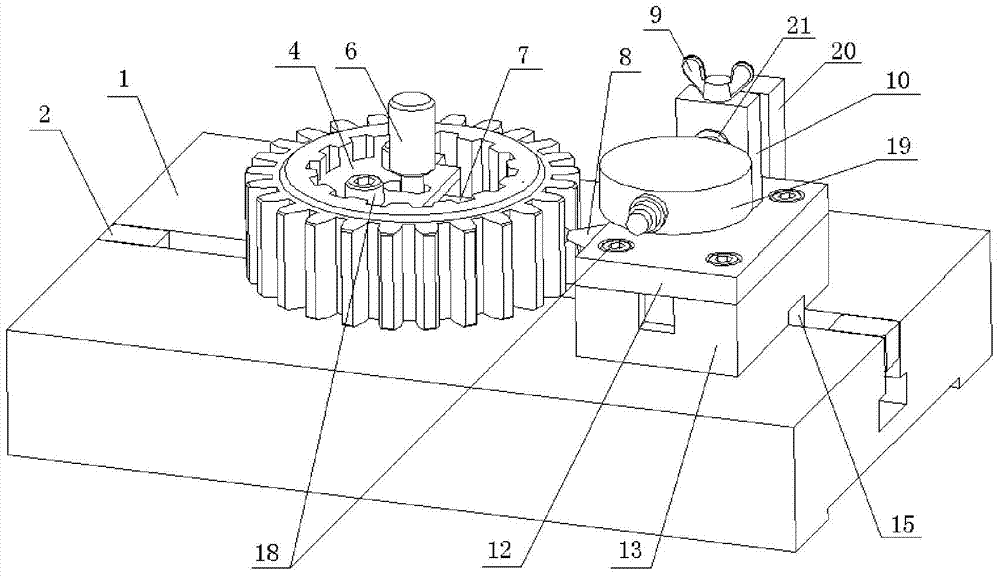

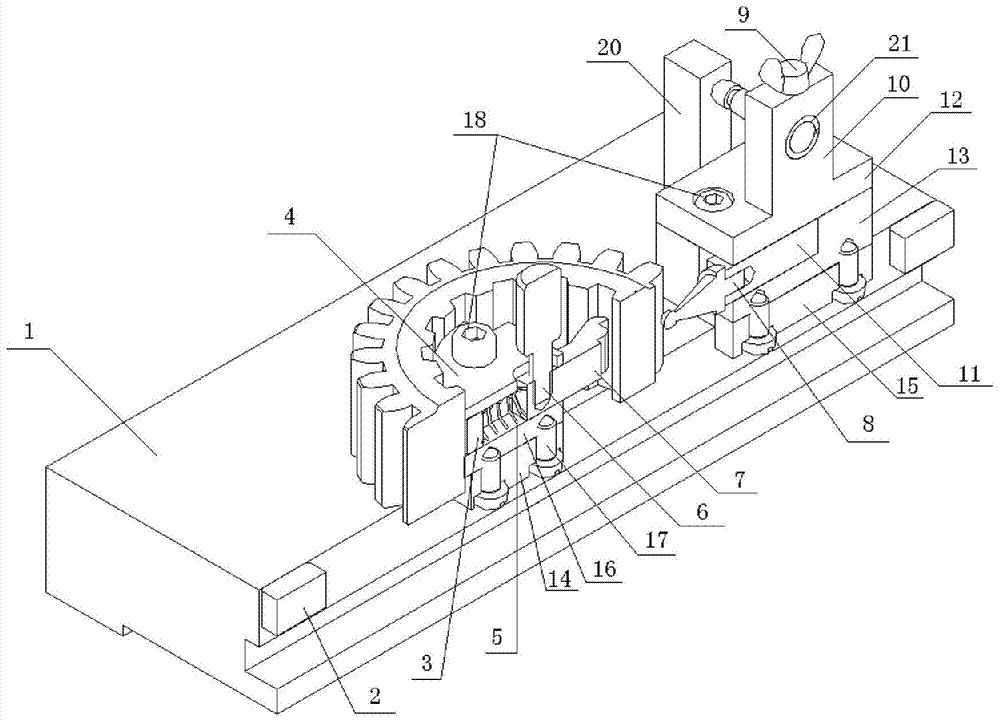

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0027] see figure 1 , 2, 3, 4, 5, the present invention includes a base 1 with an inverted T-shaped linear groove in cross-section, the bottom of the gear tightening mechanism and the symmetry display mechanism are respectively installed with the first hexagon socket head cap screw 17 capable of The first positioning key 14 and the second positioning key 15 are snapped into the inverted T-shaped structure of the linear groove, the gear tightening mechanism and the symmetry display mechanism can slide along the linear groove, and the two ends of the linear groove are installed for The stopper 2 that prevents the gear tightening mechanism and the symmetry display mechanism from sliding out of the base 1;

[0028] The gear tightening mechanism includes a semi-cylindrical centering semicircle block 16, the longitudinal section of the centering semicircle block 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com