Automobile instrument driving information automatic testing system based on CAN bus and vision detection

A CAN bus and automated testing technology, which is applied in the electrical field, can solve problems such as unstable test quality, high labor hours, and long test cycles, and achieve the effects of saving hardware installation costs, improving test quality, and improving test efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

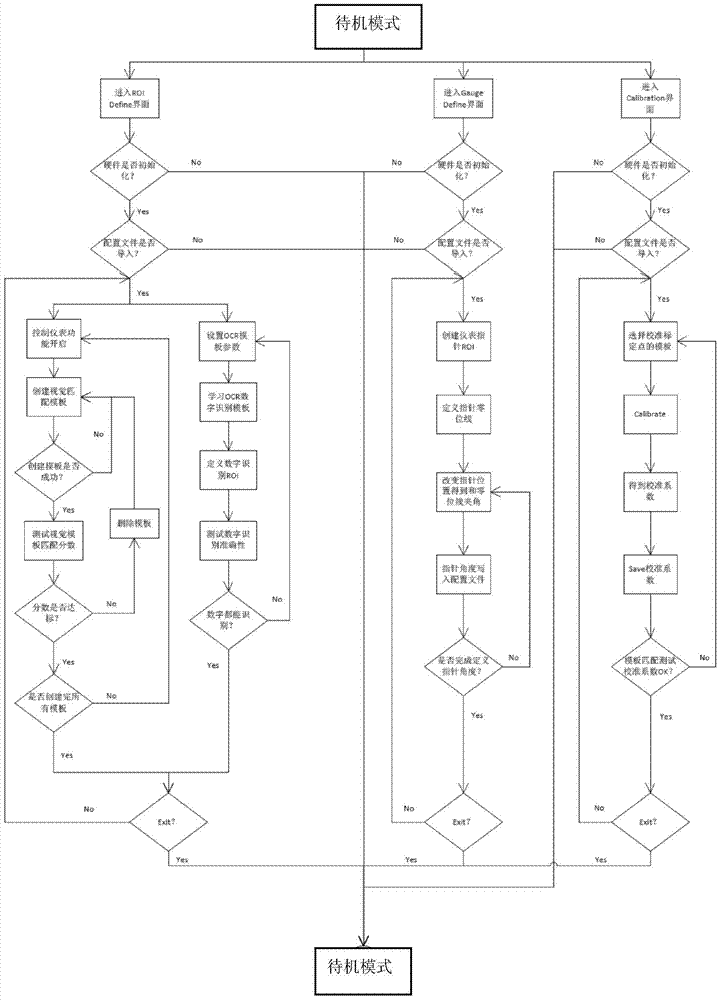

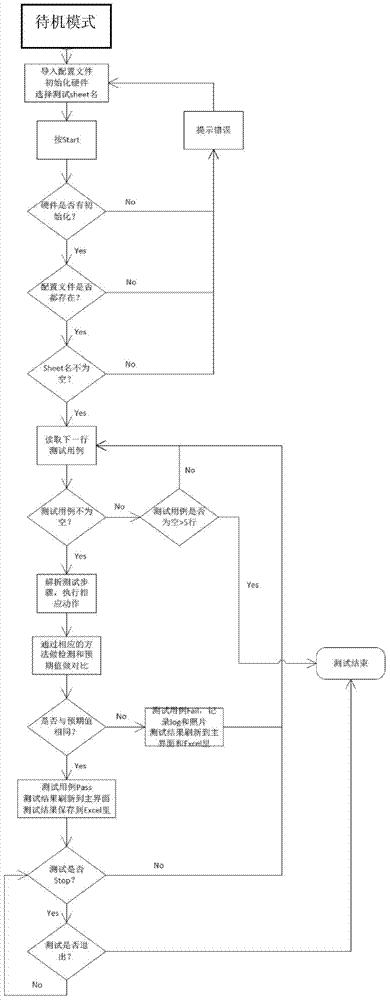

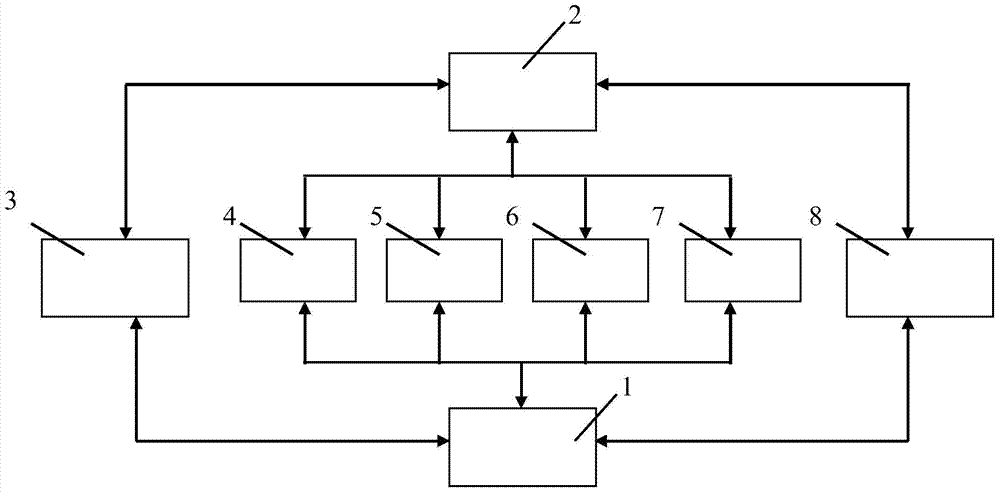

[0020] Such as figure 1 As shown, the automatic test system for driving information of automobile instruments based on CAN bus and visual detection of the present invention includes a computer 1, an instrument fixture (not shown in the figure), a three-axis movable camera support (not shown in the figure), and a visual test cassette (not shown in the figure), server 2, high-speed camera 3, controller (not shown in the figure), program-controlled power supply 4, digital multimeter 5, program-controlled resistor control board 6, relay control board 7 and CAN bus interface device 8, the The controller includes a single-chip microcomputer, wherein the instrument fixture and the three-axis movable camera bracket are all arranged in the described visual test cassette, and the described high-speed camera 3 is arranged on the described three-axis movable camera bracket , the video output signal line of high-speed camera 3 is connected with described computer 1 and server 2 respectivel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com