High and low temperature testing apparatus for mechanical test

A high and low temperature test and mechanical test technology, which is applied in the direction of applying stable tension/pressure to test the strength of materials, can solve the problems that it is difficult to reach ultra-low temperature, difficult to control temperature, and unable to meet the increasing test temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

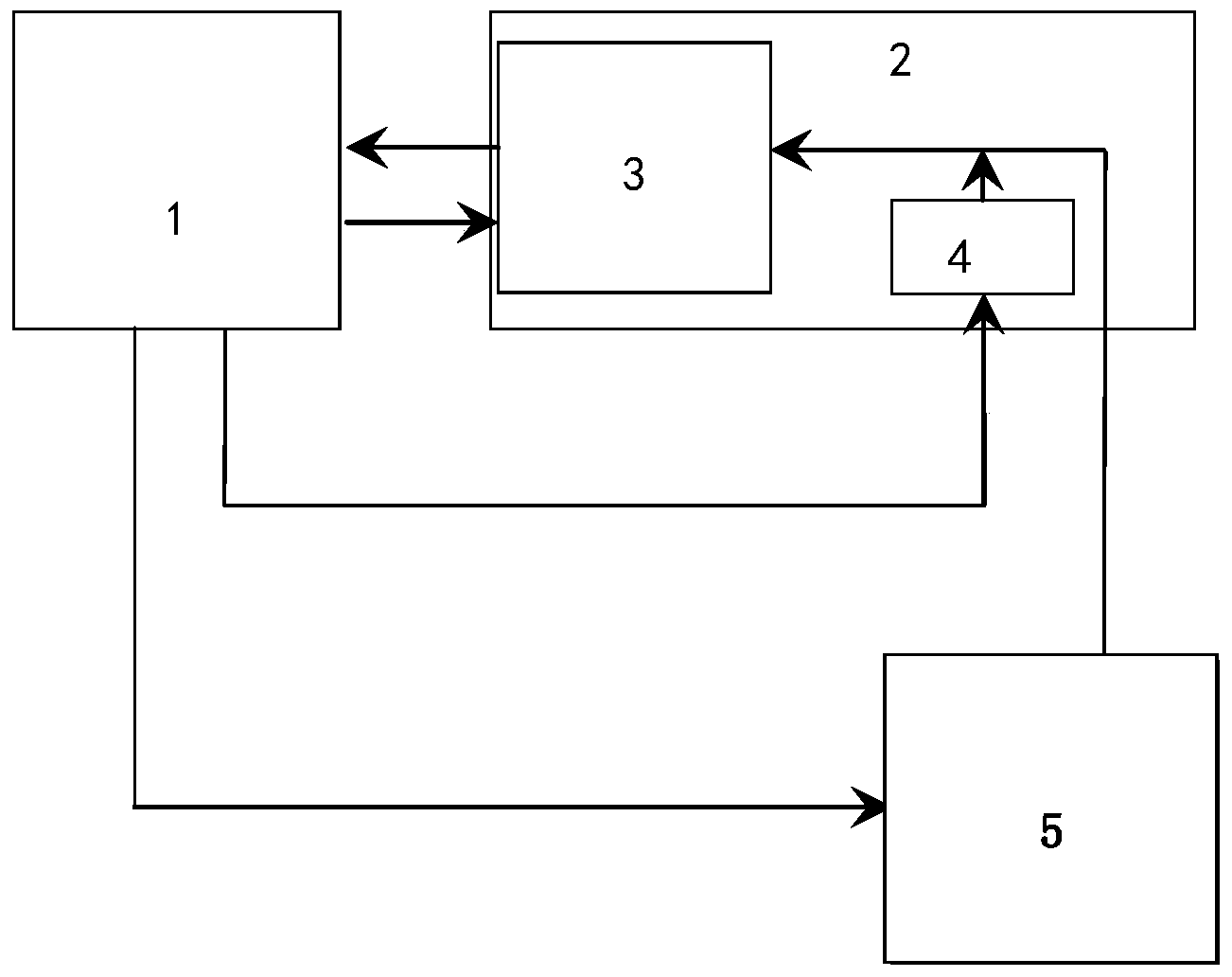

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

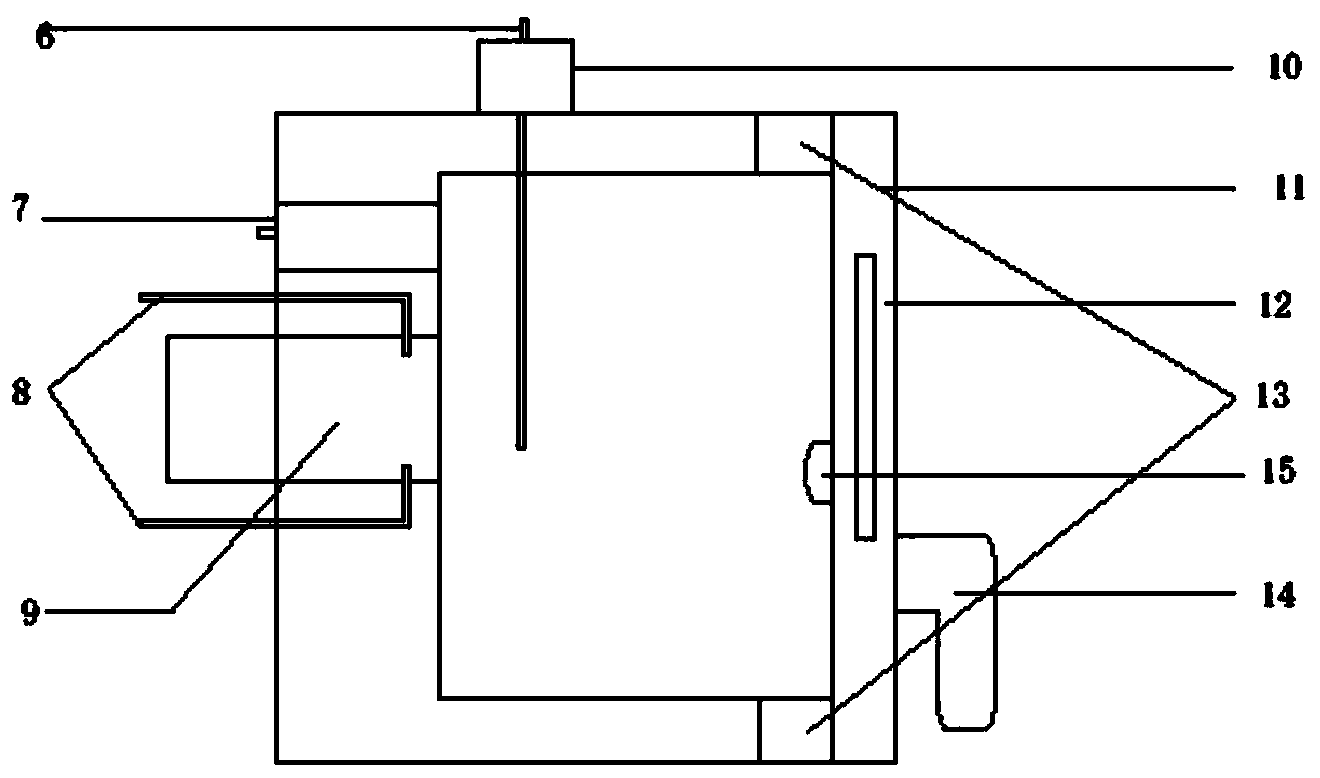

[0022] Embodiment 1: Mechanical test at ultra-low temperature

[0023] The present invention is used together with the mechanical testing machine, first clamp the high and low temperature resistant fixture with the mechanical testing machine, open the box door 11, remove the upper and lower movable insulation inserts 13, and move the upper and lower ends of the high and low temperature resistant fixture into the movable In the gap of the heat preservation insert 13, clamp the sample with a high and low temperature resistant clamp. Insert movable insert 13 then, fill up specific sand wool in the gap, close box door 11. Turn on the electrical control system, and at the same time turn on the refrigeration control system 5, input liquid nitrogen into the box through the liquid nitrogen connection pipe 8, the liquid nitrogen evaporates and cools down, and then starts to cool down, and turns on the circulation fan 9 to keep the temperature in the box uniform and stable, and through ...

Embodiment 2

[0024] Embodiment 2: mechanical test under high temperature

[0025] Use the present invention in combination with a mechanical testing machine, first clamp the high and low temperature resistant fixture with the mechanical testing machine, open the box door 11, remove the up and down movable insulation insert 13, and move the upper and lower ends of the high and low temperature resistant fixture into the movable In the gap of the heat preservation insert 13, clamp the sample with a high and low temperature resistant clamp. Insert movable plug-in block 13 then, fill up specific aluminum silicate fiber felt in the gap, close box door 11. Turn on the power control system, and turn on the heating control system 4 at the same time, and heat up through the heating resistance wire 7, that is, start to heat up, turn on the circulation fan 9 through the electrical control system to keep the temperature in the box uniform and stable, and transmit the real-time temperature inside the bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com