Determination method of fan blade crack position

A technology for fan blades and determination methods, which is applied to the use of sound waves/ultrasonic waves/infrasonic waves to analyze solids, special data processing applications, instruments, etc., which can solve the difficulty of increasing equipment maintenance, cannot specifically detect cracks, and cannot effectively avoid blades. Crack economic loss and other problems, to achieve the effect of reducing unplanned production stoppage, fast diagnosis and reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but should not be used to limit the scope of the present invention.

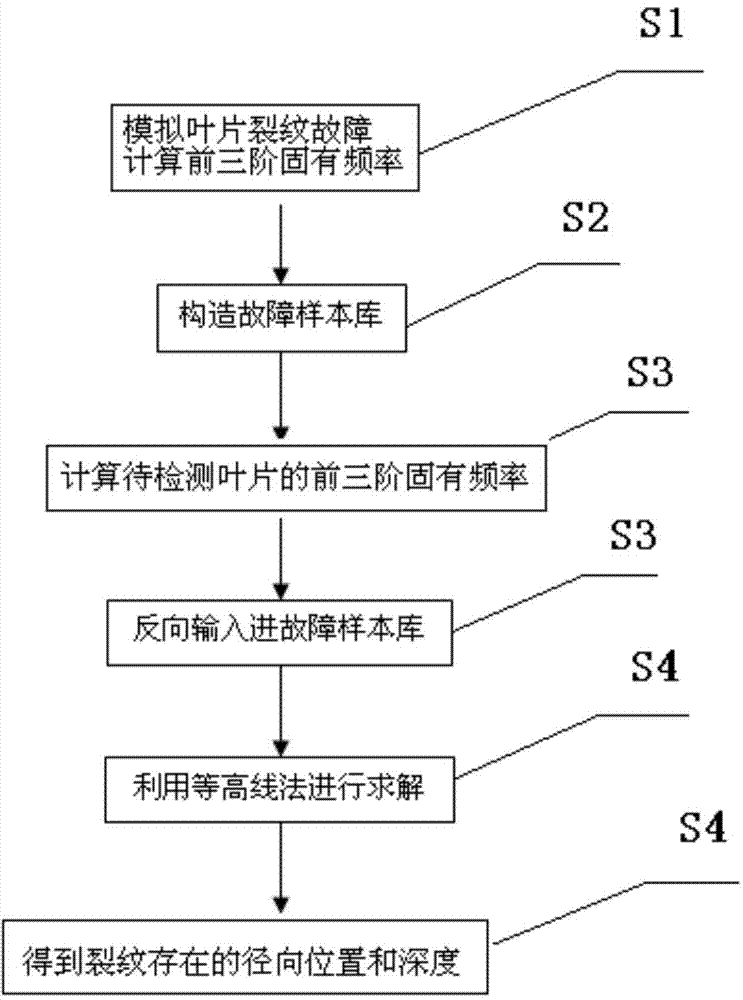

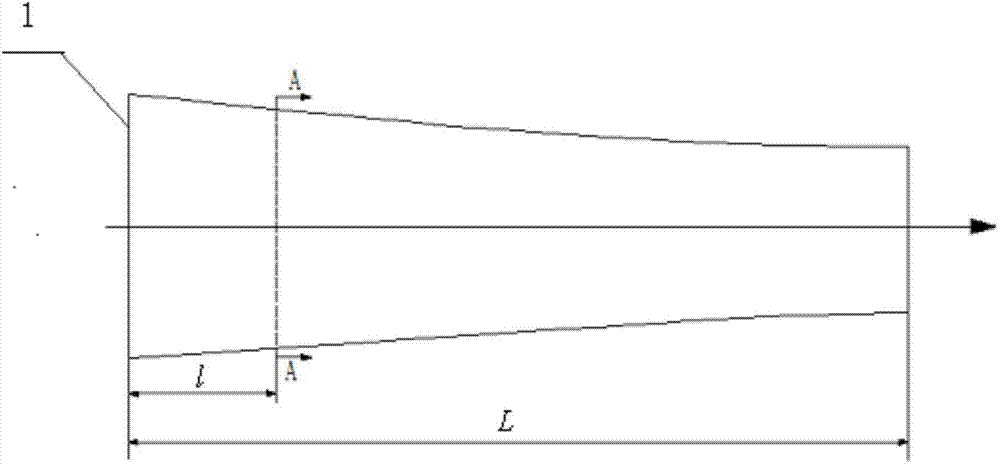

[0027] figure 1 It is a flow chart of a method for determining the position of a fan blade crack of the present invention; the method for buying that in this method comprises the following steps:

[0028] S1. Simulate the occurrence of crack faults at different positions of the blade, and calculate the first three natural frequencies;

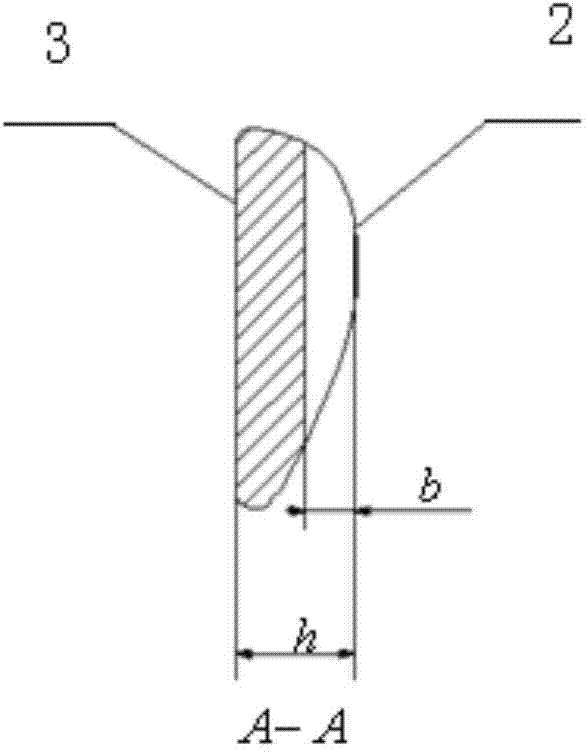

[0029] S2. Taking the natural frequency of each order, the relative depth of the crack, and the relative radial position of the crack as coordinate axes, draw a natural frequency solution surface diagram, and construct a fault sample library;

[0030] S3. During blade fault diagnosis, obtain the first three natural frequencies of the blade through calculation, and reversely ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com