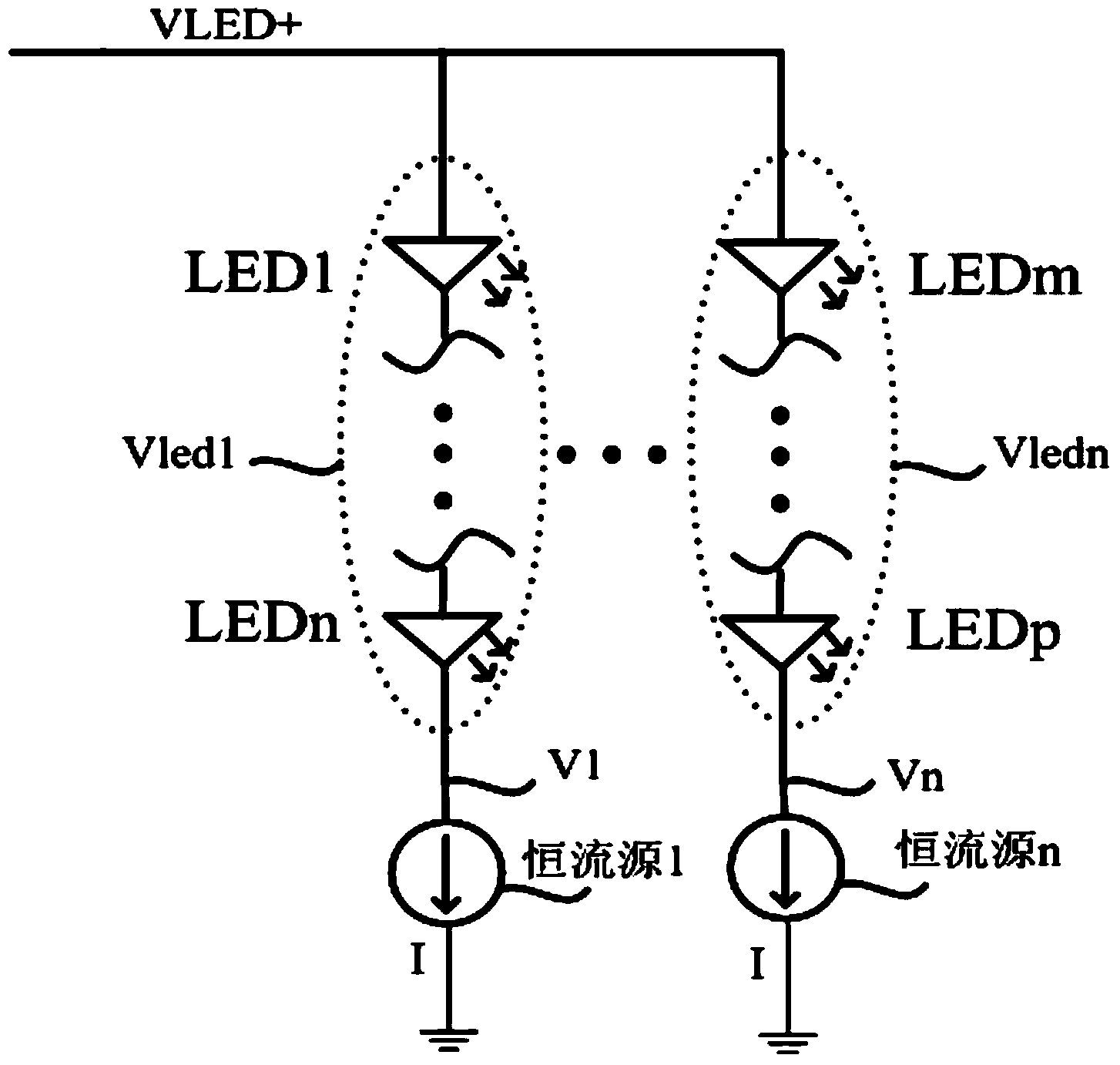

Device for measuring voltage difference between LED string lights

A technology of LED light strings and voltage difference, which is applied in the direction of using digital measurement technology for measurement, etc., can solve the problems of burning out post-stage components, large heat generation, and high working power, and achieve the effect of improving product reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention aims to provide a measuring device for the voltage difference between LED light strings, so as to quickly detect the voltage difference of each LED light string during operation, improve the production yield of the production line, and ensure product reliability.

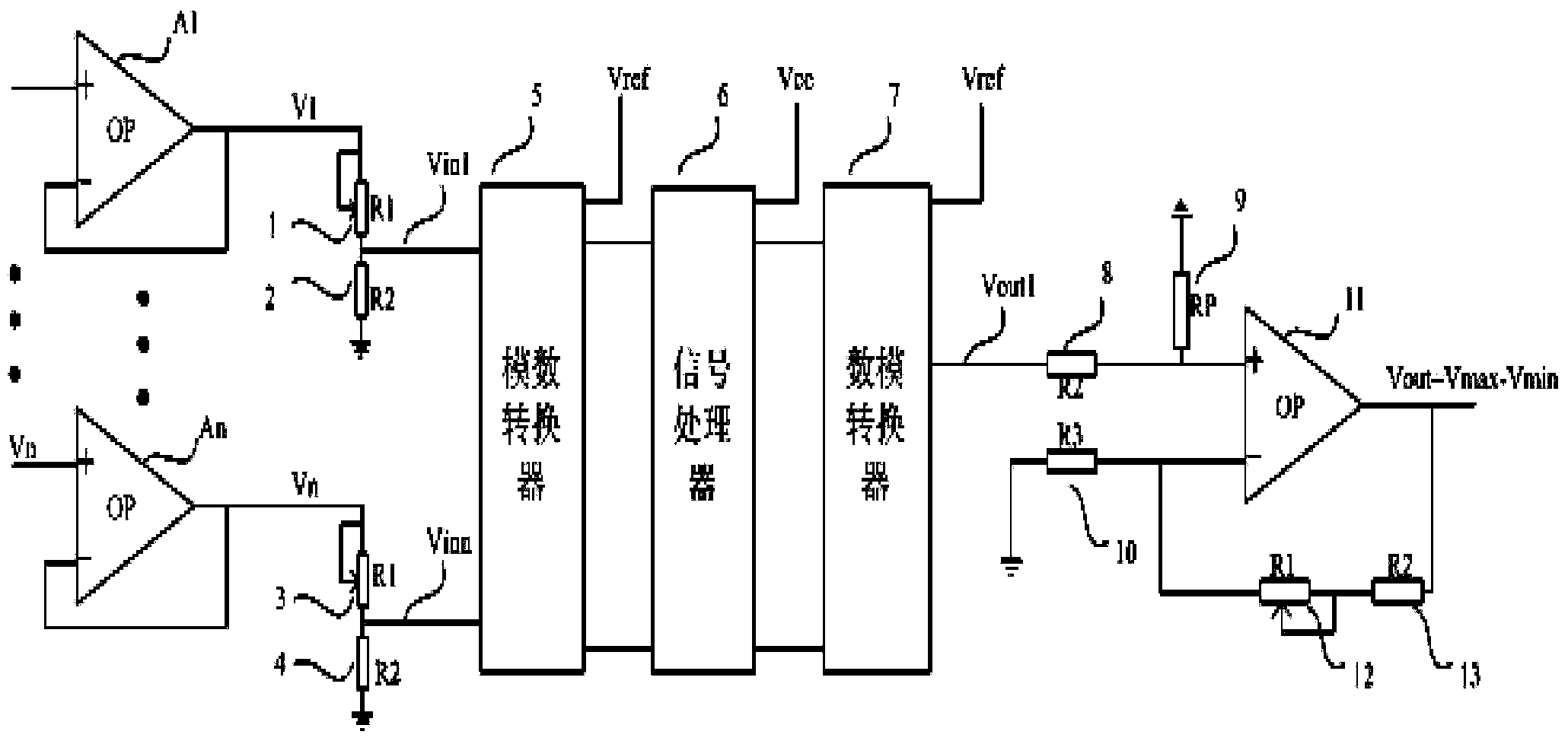

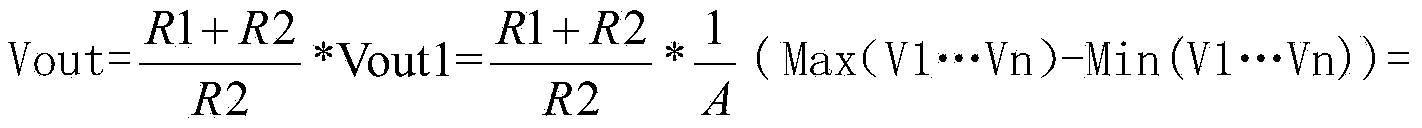

[0015] The present invention samples the voltage value on the rear constant current components of each LED light string, isolates it through a voltage follower circuit composed of an operational amplifier, and inputs it into an analog-to-digital converter to perform analog-to-digital conversion on the sampled target voltage. At this time, if the sampled voltage is too high, the sampled voltage can be processed with a certain voltage division ratio by adjusting the variable resistor, and then sent to the analog-to-digital converter for conversion. After the analog-to-digital conversion, the target voltage is input to the signal processor to perform the work of distinguishing the maximum vo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com