Torpedo ladle quantity calculation method applied to steel and iron works

A calculation method and technology for torpedo tanks, which are applied in the fields of calculation, manufacturing computing systems, special data processing applications, etc., can solve the problem of inability to obtain the turnover number of torpedo tanks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028]Taking steel plant A as an example, there are two 1350m 3 There are 2 continuous casting machines in the blast furnace and steelmaking plant, among which 1# continuous casting machine casts an average of 32 furnaces in one casting, and 2# continuous casting machine casts an average of 30 furnaces in one casting. Calculate the number of torpedo tanks required by A steel plant T for 24h.

[0029] The method for calculating the number of torpedo tanks in this embodiment is:

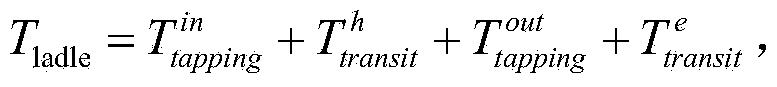

[0030] (1) Using the attached figure 1 The analysis method for the operation process of torpedo tanks shown is to analyze the operation process of torpedo tanks in A steel plant, and it is concluded that the turnover path of torpedo tanks sent to the steelmaking plant is: blast furnace-transfer area-can dumping station-transfer area-blast furnace; The turnover path of the torpedo tanks sent to the cast iron machine is: blast furnace-transfer area-cast iron machine-transfer area-blast furnace.

[003...

Embodiment 2

[0062] On the basis of Example 1, it is set that the effective volume utilization factor of the blast furnace in Example 1 is changed from 2.2 to 2.0, and 2 continuous casting machines in the steelmaking plant work at the same time. Within 24 hours, 1# continuous casting machine casts 34 furnaces, 2 #Continuous casting machine casts 32 furnaces. Also use the attached figure 1 The analysis method of the operation process of the torpedo tank and the calculation method of the turnover period are shown to analyze the torpedo tank.

[0063] (1) Analyze the relationship between blast furnace iron production and continuous casting machine iron demand

[0064] Use blast furnace iron production formula of the present invention to calculate blast furnace iron production:

[0065] Q BF = Σ i = 1 N ...

Embodiment 3

[0078] On the basis of Example 1, it is set to change the effective volume utilization factor of the blast furnace in Example 1 from 2.2 to 2.0, and two continuous casting machines in the steelmaking plant work at the same time, wherein 1# continuous casting machine casts 32 furnaces, and 2# continuous casting machines The casting machine casts 30 furnaces. Also use the attached figure 1 The analysis method of the operation process of the torpedo tank and the calculation method of the turnover period are shown to analyze the torpedo tank.

[0079] (1) Analyze the relationship between blast furnace iron production and continuous casting machine iron demand

[0080] Utilize formula of the present invention to calculate blast furnace iron yield, as follows:

[0081]

[0082] Choose the metal recovery rate of converter to continuous casting machine to be 99%, iron-to-steel ratio is 88%, use formula of the present invention, calculate continuous casting machine to need iron am...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com