Miniaturized switch cabinet of handcart type

A handcart-type switch and handcart-type technology, applied in the field of switch cabinets, can solve problems such as complicated operation interlocking, circuit breaker shaking, and incomplete interlocking, so as to achieve safe and reliable operation, reduce the overall width, and reduce the occupied area Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

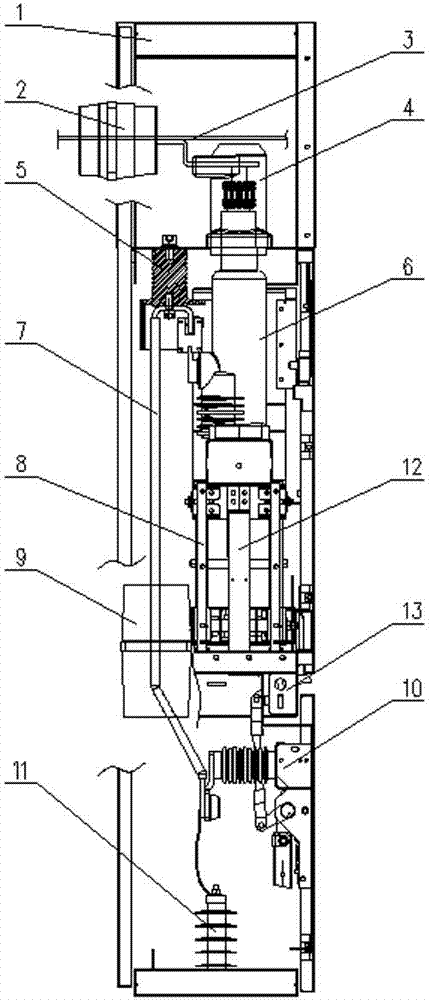

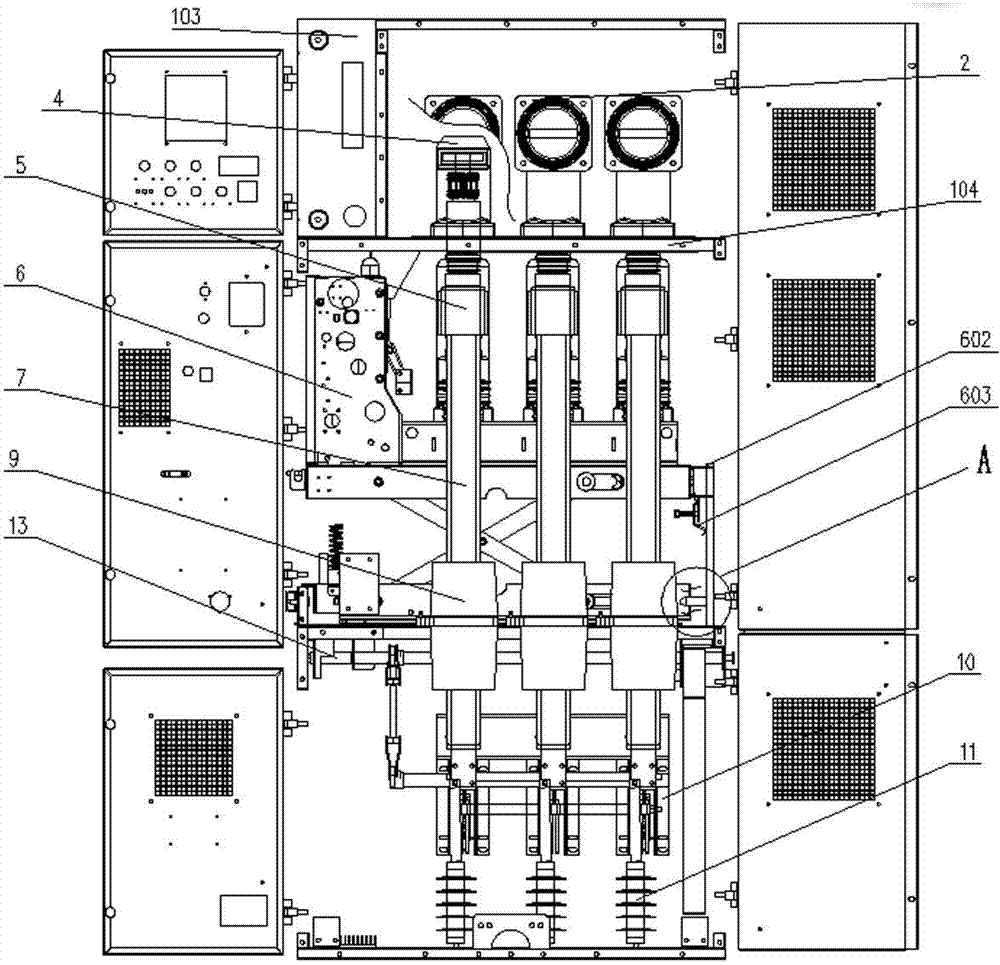

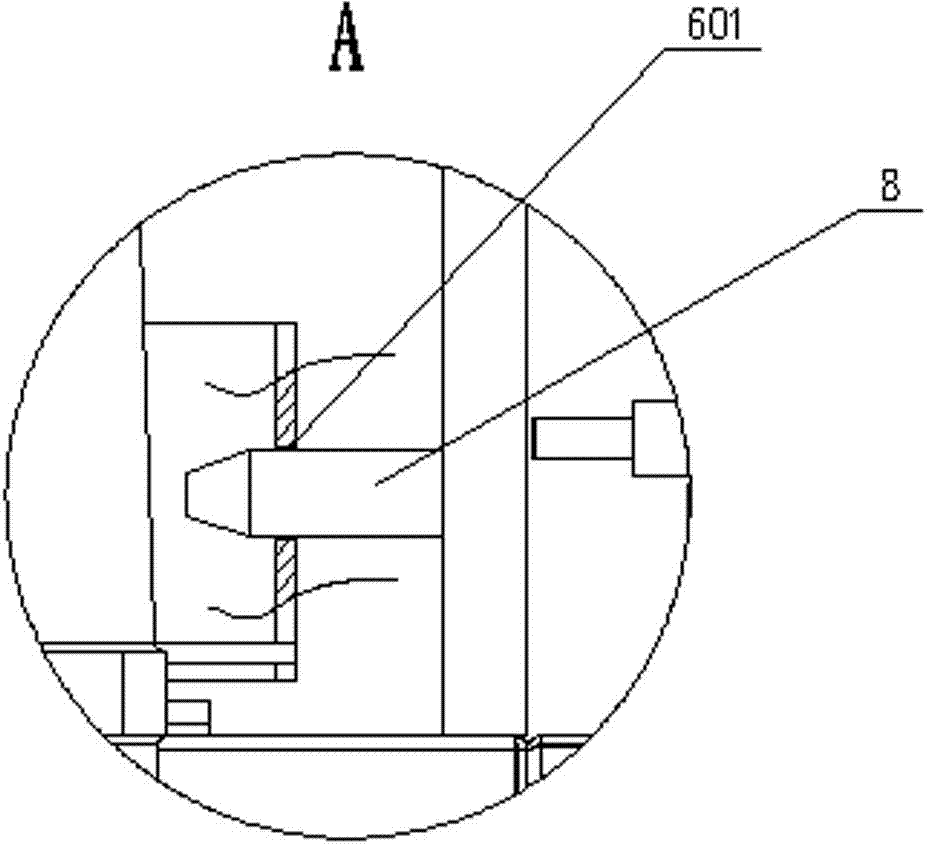

[0029] refer to Figure 1-10 , the specific embodiment adopts the following technical solutions: a miniaturized handcart switchgear, including a housing 1, a wall bushing 2, a main bus 3, an upper contact box 4, an insulating cover 5, a side-mounted handcart type Vacuum circuit breaker 6, lower bus bar 7, guide rail guide rod 8, current transformer 9, grounding switch 10, overvoltage protector 11 and grounding bar 12, housing 1 consists of left side panel 101, right side panel 102, instrument box 103, contact box mounting plate 104, circuit breaker seat plate 105, guide rail bending plate 106, left tongue plate fixing plate 107, right tongue plate fixing plate 108, upper cover plate 109, and bottom cover plate 110, circuit breaker seat plate The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com