Production process and use of mulberry leaf tea

A production process, the technology of mulberry leaf tea, which is applied in the fields of application, food preparation, tea substitutes, etc., can solve the problems of large damage to physiologically active substances, high processing cost, unfavorable staff operations, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Embodiment 1, a kind of manufacture craft of mulberry leaf tea, comprises steps successively:

[0038] (1) Picking mulberry leaves;

[0039] (2) Wash the mulberry leaves first, then dry them;

[0040] (3) Selection and sorting of mulberry leaves;

[0041] (4) Cut into mulberry leaf strips by a cutting device, and remove the petioles and main veins of the mulberry leaves before cutting;

[0042] (5) The mulberry leaf strips are firstly de-enzymed by a de-enzyming machine, and then cooled;

[0043] (6) The mulberry leaf strips are kneaded by a kneading machine;

[0044] (7) The mulberry leaf strips are dried by a drying device;

[0045] (8) Stir fry the mulberry leaf strips to form granular initial mulberry leaf tea;

[0046] (9) The initial mulberry leaf tea is first passed through an aroma enhancer to enhance the aroma, and then the temperature is cooled to form the final mulberry leaf tea.

[0047] After the mulberry leaves are picked, they ...

Embodiment 2

[0051] Example 2, the difference between it and Example 1 is: there is also a step of rehydrating the mulberry leaf strips between step (7) and step (8): placing the dried mulberry leaf strips in the bamboo flat, Then lay a quilt on the top of the bamboo flat, and then let it stand for 5-15 minutes. In the process of ensuring that the previous process is fully completed, a certain amount of water is recovered from the outer part of the mulberry leaf strips, which can be fully utilized during the frying process. It will not be burnt, but also can get very high-quality mulberry leaf tea. The content indicators of various nutritional components have been greatly improved, and the average increase rate is more than 7%.

Embodiment 3

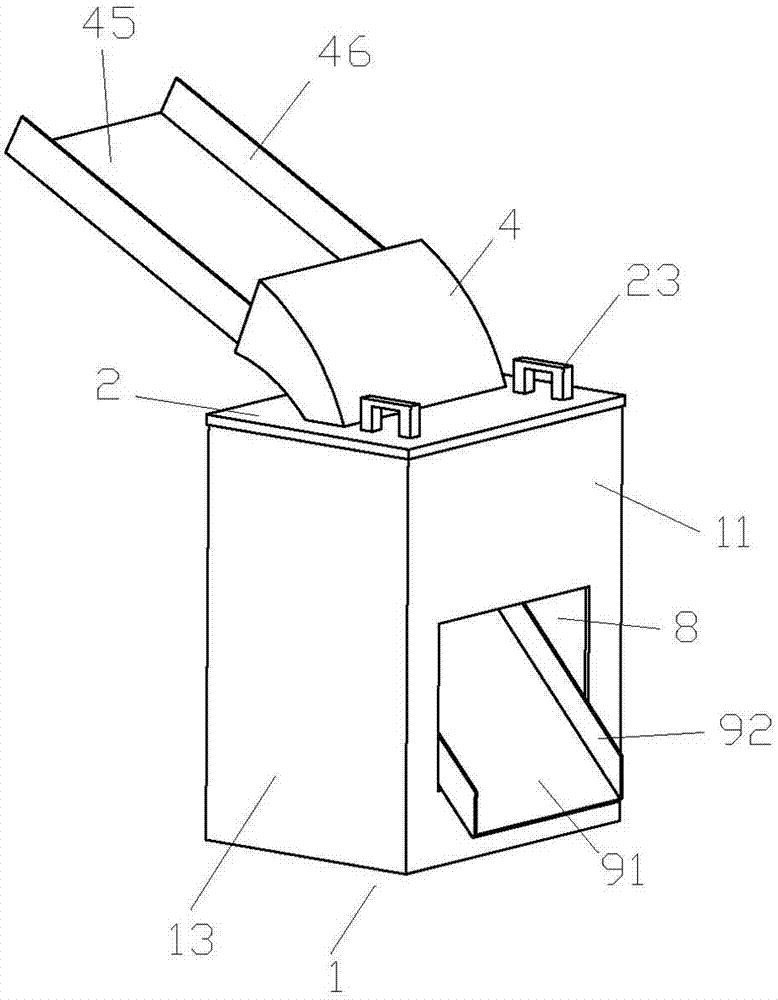

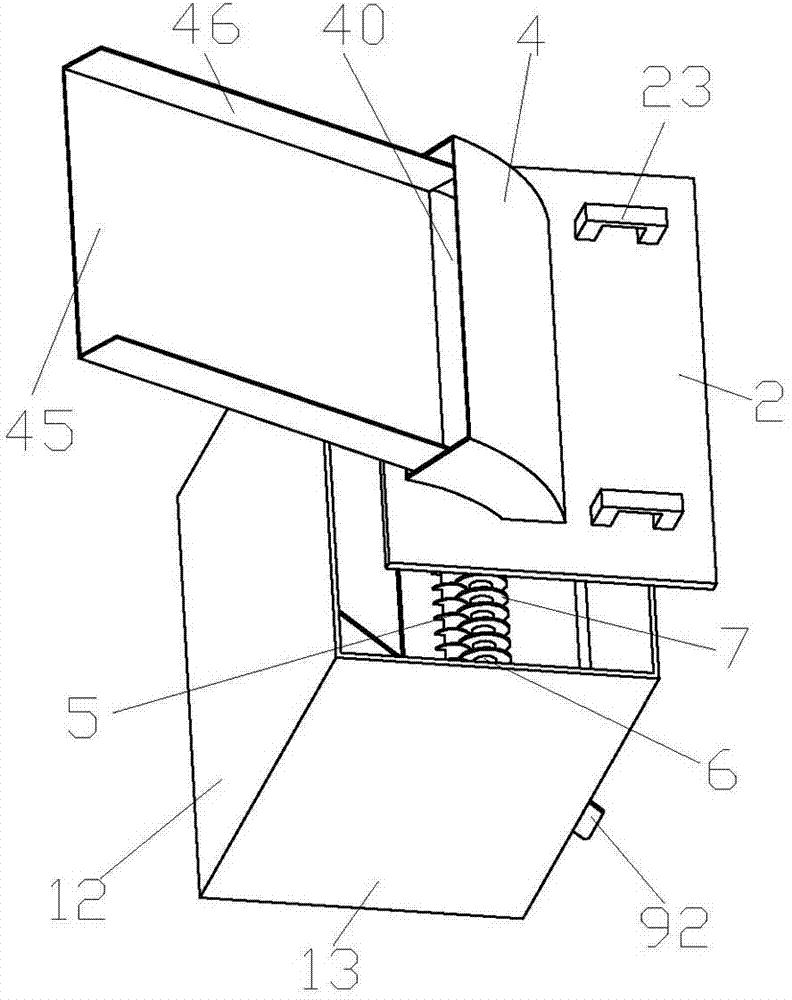

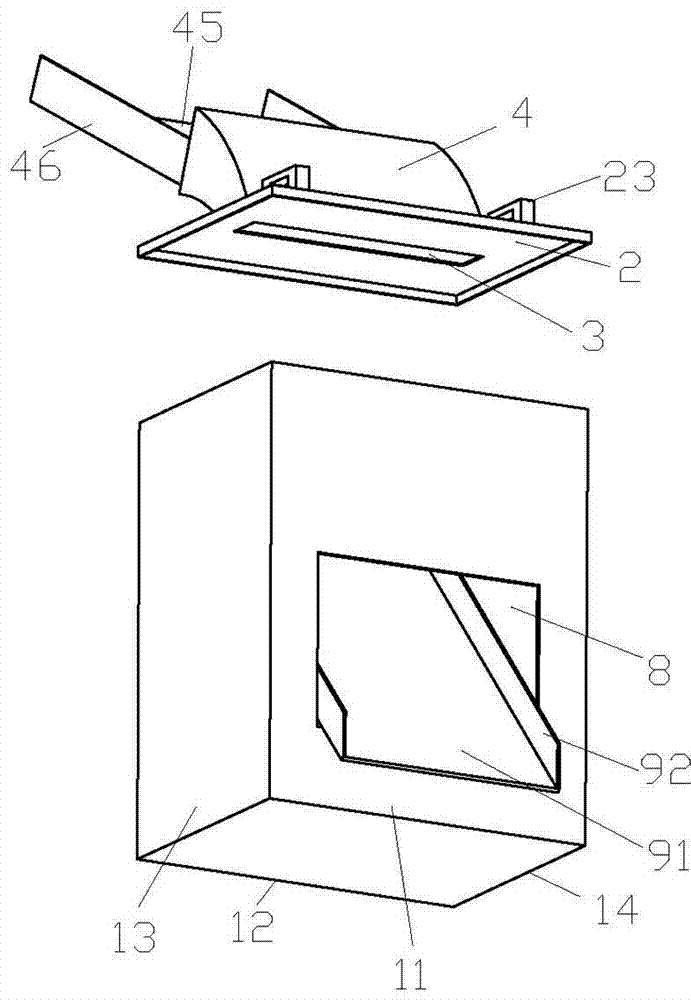

[0052] Example 3, such as figure 1 , 2 , 3, the difference between it and Embodiment 1 is that the cutting device is different, the cutting device of the present embodiment includes a working box 1 below, and the working box 1 includes end-to-end and surrounds a cuboid or cube The front side box 11 and the rear side box 12, as well as the left side box 13 and the right box 14 on both sides, the upper end of the working box 1 is equipped with a guide box cover 2 that can cover the working box 1, The guide box cover 2 is provided with an introduction port 3 that communicates with the inner cavity of the working box body 1 in the up and down direction. The guide box cover 2 is located on the outside of the work box body 1 and is fixed with a mulberry leaf entering the compression neck 4 along the edge of the introduction port 3. The mulberry leaf enters the compression neck 4 and has a neck compression passage 40 communicated with the introduction port 3. The cross-sectional...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com