Process for manufacturing fabric capable of preventing radiation of electromagnetic waves

A technology for preventing electromagnetic waves and preparation process, applied in textiles, papermaking, yarn and other directions, can solve problems such as large differences in shielding effectiveness, and achieve the effects of outstanding reflection performance, low price and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A preparation process for an anti-electromagnetic wave radiation fabric, the anti-electromagnetic wave radiation fabric is made of natural cotton fiber, synthetic fiber polyester staple fiber and stainless steel metal short fiber blended and interwoven, containing 30% of stainless steel fiber, 35% of cotton, and 35% of polyester Including the shearing process of stainless steel fiber filament bundles, the drawing process of stainless steel fiber blended yarn, the roving process of stainless fiber blended yarn, the spun process of stainless steel fiber blended yarn, and the winding process of stainless steel fiber blended yarn;

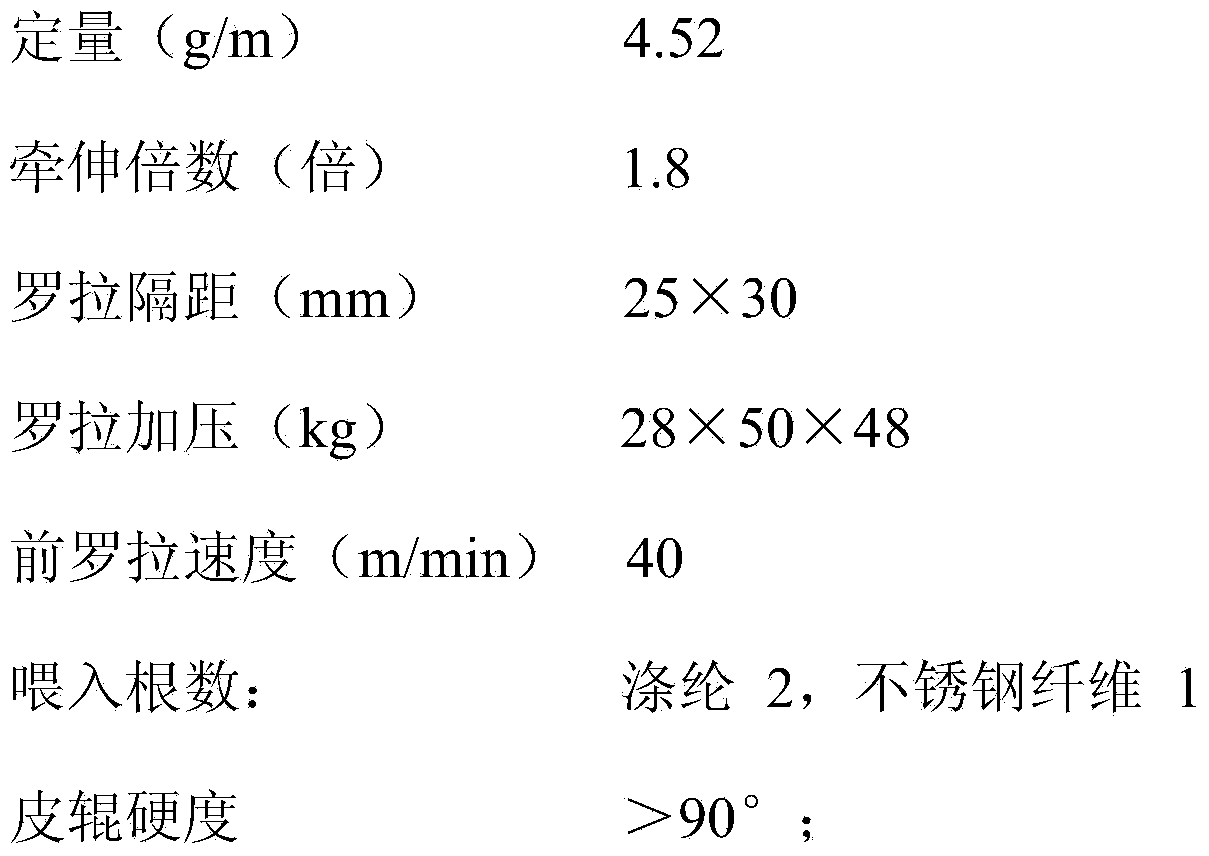

[0037] The main process parameters of pulling and cutting are:

[0038]

[0039] The head and main process parameters are:

[0040]

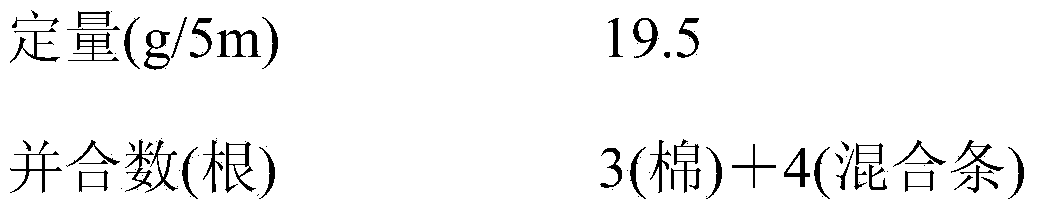

[0041] Two and the main process parameters are:

[0042]

[0043]

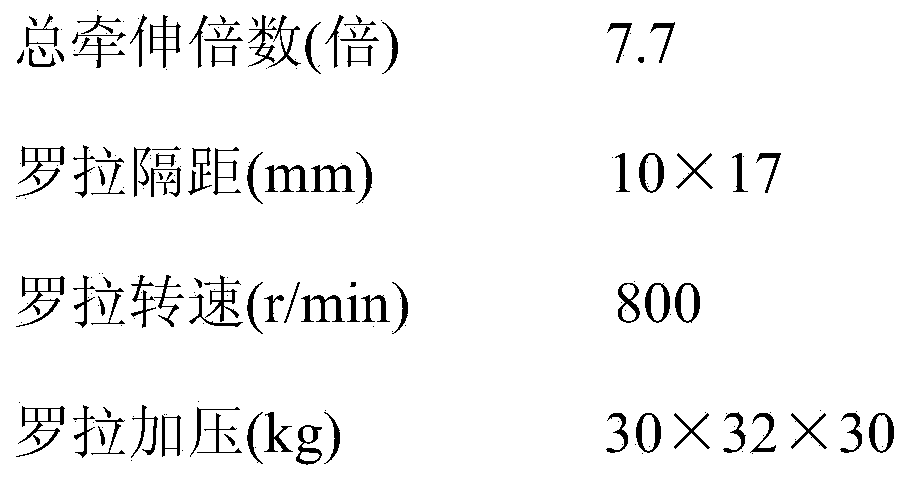

[0044] Three and the main process parameters are:

[0045]

[0046] The main process parameters of spun yarn are:

[0047]

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com