a cooling fabric

A cooling and fabric technology, applied in the field of clothing fabrics, can solve problems such as application limitations, increased twist number, and insufficient fabric feel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

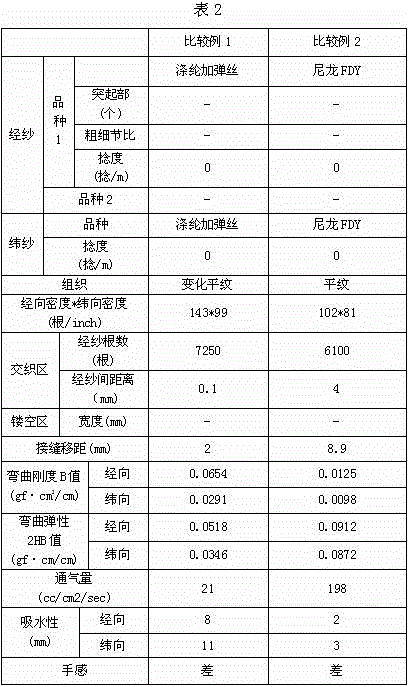

[0040] The warp is made of 150D-36f cationic dyeable polyester coarse detail processing yarn and conductive fiber, and the weft yarn is 45S / 2 polyester-cotton staple yarn, in which the cationic dyeable polyester coarse detail processing yarn is cationic polyester: island component ordinary poly The compound ratio of ester weight is 50:50, the diameter ratio of thick places and thin places in the length direction is 1.2:1, the twist direction is S twist, and the twist is 800 twists / m; the conductive fiber content is 0.2% by weight; in polyester-cotton spun yarn The polyester content is 65%, the cotton fiber content is 35%, and the twist is 600T / M.

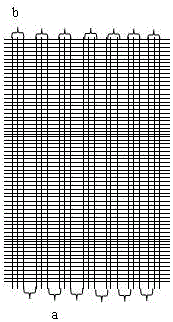

[0041] The plain weave is used for the weave, and the method of 3-in and 1-reed is used for reeding, and then the gray cloth is obtained by weaving, and then undergoes 95-degree scouring, 180-degree intermediate shaping, double-sided singeing, 5% weight-reduction rate reduction, and dyeing , resin processing, finishing and shaping t...

Embodiment 2

[0044] When reeding, adopt the method of 3 entries and 2 reeds, 4 entries and 2 reeds, and 5 entries and 2 reeds, and the rest are the same as in Example 1.

[0045] The warp density of the obtained fabric was 84 threads / inch, and the weft density was 52 threads / inch. The number of warp yarns in the interweaving area is cyclically arranged in order of 3, 4, and 5, the distance between the warp yarns in the interweaving area is 0.7 mm, and the width of the hollow area is 1.5 mm. The properties are shown in Table 1.

Embodiment 3

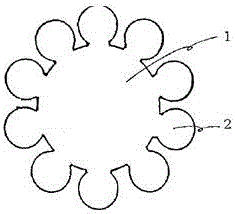

[0047] The warp and weft yarns are made of 150D-48f-common polyester textured yarn and 150D-20f-polylactic acid fiber. The arrangement ratio is 4:4, that is, 4 ordinary polyester textured yarns and 4 polylactic acid fibers are arranged adjacent to each other at intervals. The warp and weft twists are both 1000 twists / inch. The weave is a variable plain weave, the reeding is a 2-in-and-through method, and then weaves to obtain a gray cloth, and then undergoes scouring, intermediate setting, weight reduction processing, dyeing, finishing and setting to obtain the cooling feeling fabric of the present invention. During weight reduction processing, since the polylactic acid fiber is very soluble in alkali, the polylactic acid fiber is completely dissolved. The decrement condition is: the decrement solid caustic soda concentration in cylinder is 4%, and temperature is 95 ℃, and decrement time is 15 minutes, and decrement rate is 58%.

[0048] The warp of the obtained fabric did n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com