Method of pouring concrete in steel pipe column

A technology for pouring concrete and steel pipe columns, applied in the field of concrete pouring, which can solve the problems of difficulty in pouring concrete and ensuring the compactness of concrete in columns, etc., and achieve the effects of short construction preparation time, easy control and low requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

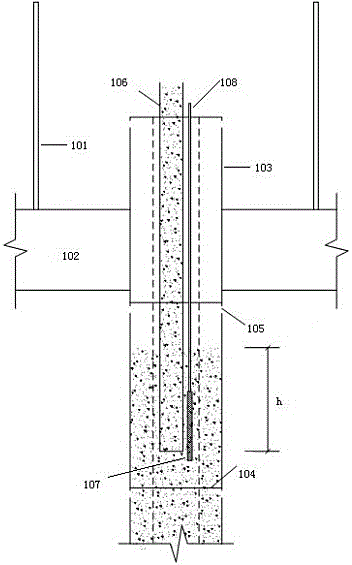

Image

Examples

Embodiment Construction

[0016] The technical solutions of the embodiments of the present invention will be clearly and completely described below with reference to the accompanying drawings. Obviously, the described embodiments are only a part of the embodiments of the present invention, rather than all the embodiments. Based on the examples in the present invention, all other embodiments obtained by those of ordinary skill in the art without creative efforts shall fall within the protection scope of the present invention.

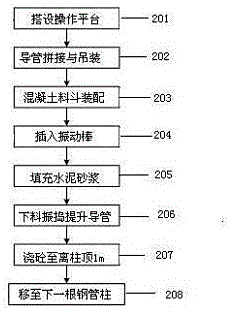

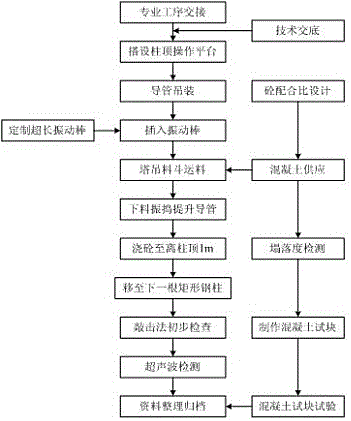

[0017] Before implementing the construction technique of the present invention, the following construction preparations need to be carried out:

[0018] 1. Pre-job training and technical disclosure. The concrete conduit pouring method in the steel tube column has strong continuity and requires coordinated operation of multiple teams and multiple types of work. Be sure to let the managers and operators involved in the construction understand this feature. And according to the c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| slump | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com