Preparation method of high-temperature-resistant lightweight ceramic heat screen

A light-weight ceramic and heat shield technology, applied in the field of high-temperature resistant materials, can solve the problems of low service life, large renewal amount, high carbon fiber price, etc., and achieve the effect of reducing manufacturing costs and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Provide the technical solutions of the specific embodiments of the present invention in detail below, it should be noted that the description of the specific embodiments of the present invention is for the convenience of a comprehensive understanding of the technical content of the present invention, and should not be regarded as the claims of the present invention Limitation of Scope of Protection.

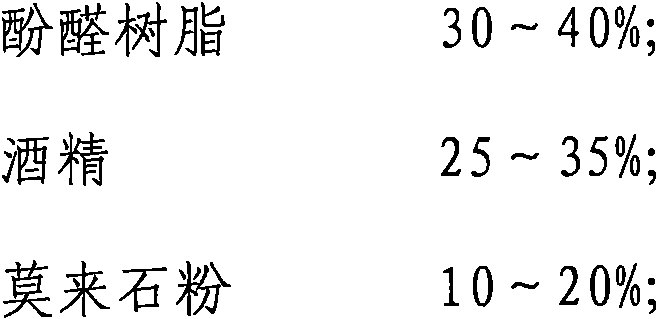

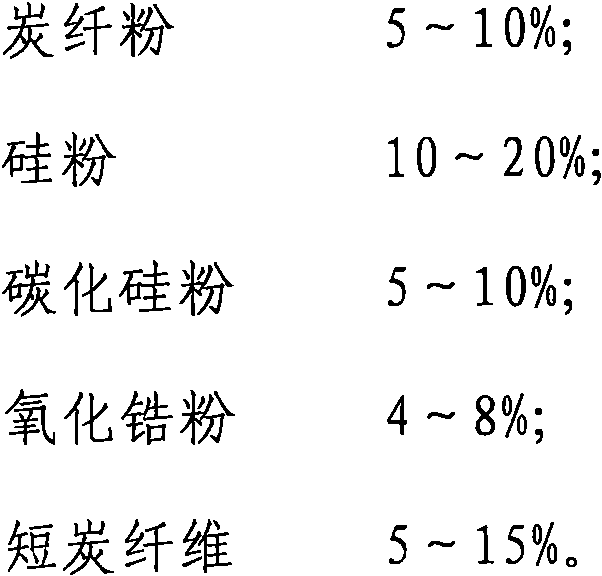

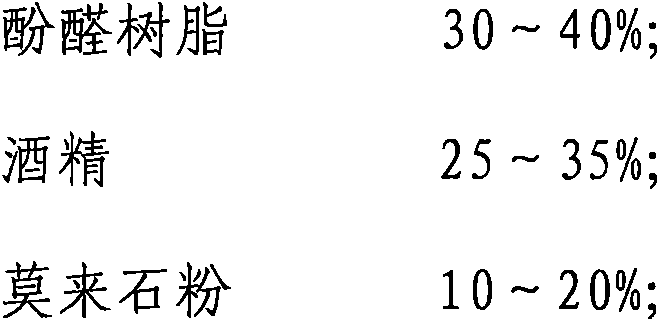

[0018] The technical solution of the specific embodiment of the present invention is: the steps of the preparation method of the described high-temperature-resistant lightweight ceramic heat shield are as follows: a. prepare a colloidal ceramic modifier for glass fiber cloth; b. After immersing in the above-mentioned colloidal ceramic modifier, take it out, bake and pre-cure at 100 ° C ~ 110 ° C to obtain a modified prepreg cloth of glass fiber cloth; c. Put the modified prepreg cloth of step b on the mold of the winding machine The upper layer is wound and formed, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com