A long-span steel bridge prefabricated deck pavement method

A bridge deck pavement and assembly technology, which is applied in the direction of erecting/assembling bridges, bridges, bridge parts, etc., can solve the problems of pouring asphalt concrete construction difficulty, construction organization complexity, construction difficulty, etc., to shorten the modulus The effect of cyclical construction cycle, uniform distribution of human resources, and improvement of construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A kind of large-span steel bridge assembly type bridge deck paving method of the present embodiment, comprises the following steps successively:

[0040] Step 1) Divide the steel bridge deck into grids to form a modular steel deck;

[0041] Step 2) processing a steel deck 1 matching each grid of the modularized steel deck;

[0042] Step 3) The steel bridge deck 1 is hoisted onto the modular steel bridge deck, and fixedly connected with the steel box girder 7 .

[0043]In this embodiment, a long-span steel bridge assembly-type bridge deck paving method divides the steel bridge deck into a grid to make the steel bridge deck modular, and adopts the steel bridge deck 1 that is processed and formed in the factory at one time, and The steel bridge deck 1 is precisely matched with the steel box girder 7, and is installed on the steel box girder 7 in blocks to form a bridge deck during paving, and is combined to form the entire bridge deck system, which has the advantages of f...

Embodiment 2

[0045] In this embodiment, a long-span steel bridge assembled bridge deck pavement method is based on the embodiment 1, and in step 2), the modified rubber 2 integrally formed on the upper surface and the peripheral side of the steel bridge deck 1 is thermally melted.

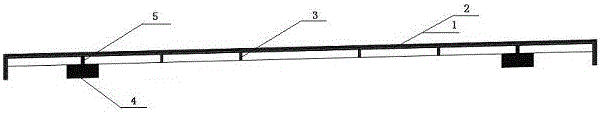

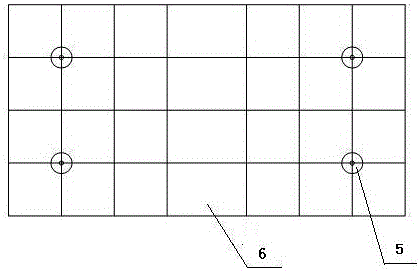

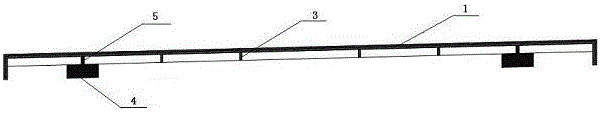

[0046] In step 3), the steel bridge deck 1 and the steel box girder are connected by high-strength bolts 5; as a preferred solution, each steel bridge deck 1 and the steel box girder 7 are connected by four high-strength bolts 5 Fixed connections are distributed on the steel bridge deck 1 in a rectangular shape. The steel bridge deck 1 is directly connected with the steel box girder 7 by high-strength bolts 5, which is convenient for installation and construction.

[0047] A rubber pad 4 is arranged between the steel bridge deck 1 and the steel box girder 7 . A high-performance rubber pad 4 is arranged between the steel bridge deck 1 and the steel box girder 7, which can reduce noise and friction between the s...

Embodiment 3

[0050] The method for laying a prefabricated deck of a long-span steel bridge in this embodiment is based on Embodiments 1 and 2. In step 1), the steel deck is divided into modular rectangular grids.

[0051] In this embodiment, the steel bridge deck 1 in step 2) is rectangular.

[0052] That is to say, the assembled steel bridge structure adopted in this example is a modular "hot-melt modified rubber 2 + steel bridge deck 1", and its specific structural diagram is as follows figure 1 , figure 2 and image 3 shown. The steel bridge deck 1 adopts industrialized and standardized production, and can be precisely matched with the steel box girder 7 on the production line, and the supporting production ensures the accuracy and quality of installation. The hot-melt modified rubber 2 is set on the steel bridge deck 1, and it is integrally formed with the steel bridge deck 1 in the factory, which can increase the ride comfort, solve the problem of driving stability and comfort, se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com