Valve positioner having bypass component and control valve comprised thereof

A valve positioner and component technology, applied in the direction of jet program control, valve device, valve details, etc., can solve the problems of increasing the cost and complexity of process lines and control system components, and achieve the effect of reducing downtime

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

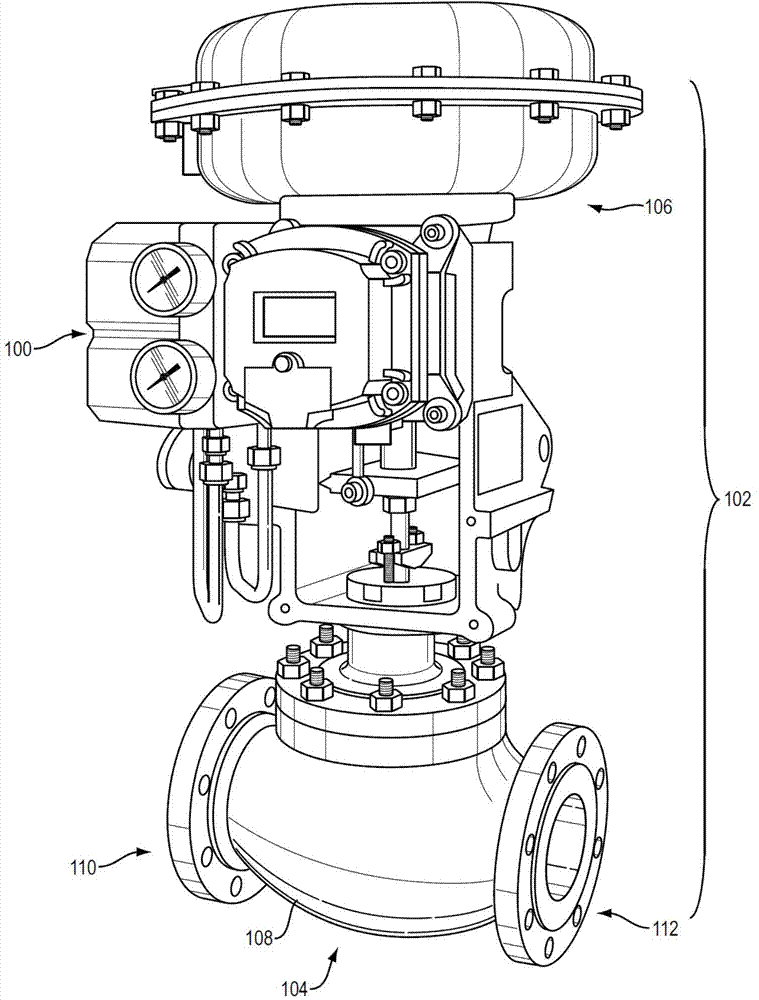

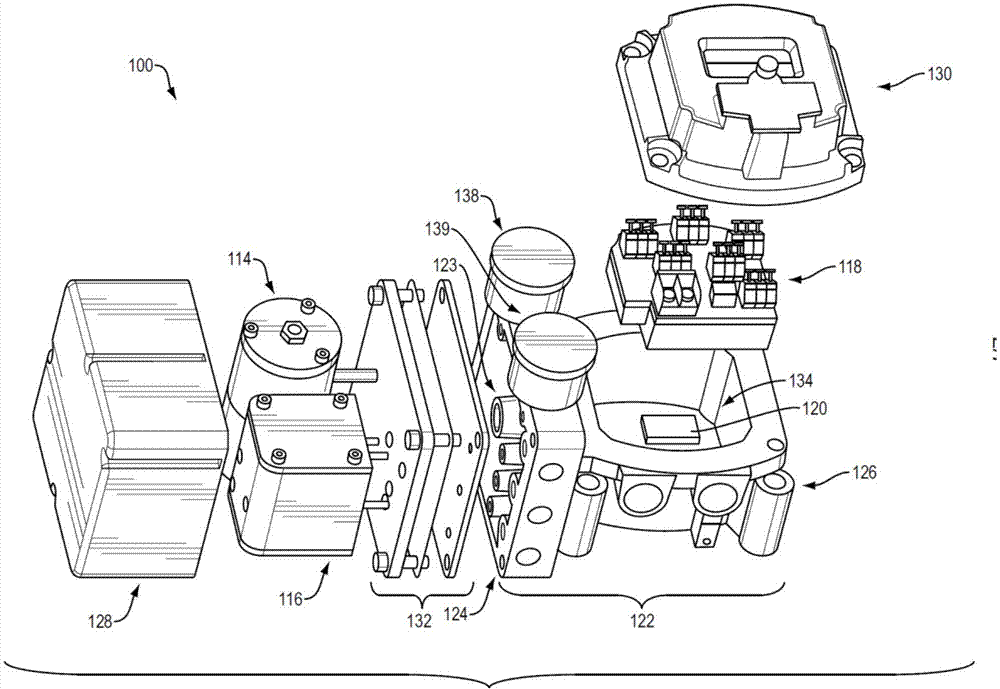

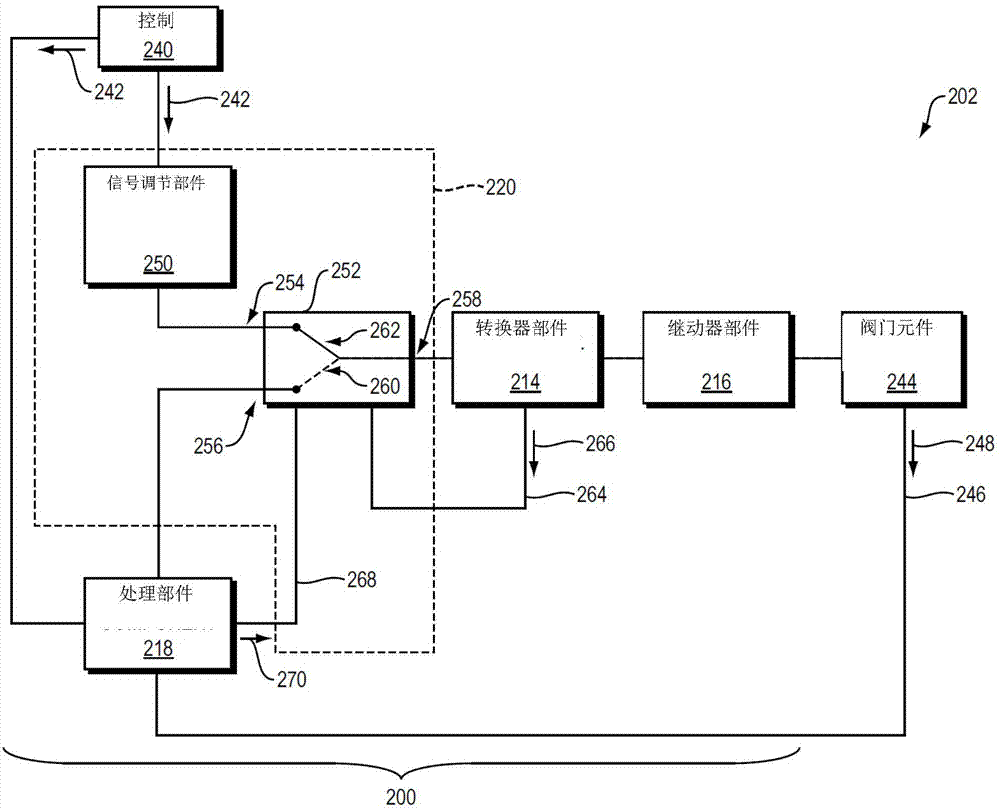

[0016] figure 1 and 2 An exemplary embodiment of a valve positioner 100 is shown having a bypass feature that continues to regulate fluid flow during in-line maintenance and repair. exist figure 1 In FIG. 1 , the valve positioner 100 is part of a control valve 102 having a fluid coupling 104 and an actuator 106 . These components of control valve 102 work in combination with valve positioner 100 to control one or more process states (eg, flow, pressure, temperature, etc.) associated with fluid flow through fluid coupling 104 . As shown, the fluid coupling 104 has a body 108 with a first inlet / outlet 110 and a second inlet / outlet 112 . The fluid coupling 104 can also have figure 1 Valves not shown in illustration. The valve is present in the body 108 . An actuator 106 is coupled to the valve to change the position of the valve (eg, from a first valve position to a second valve position). The change in position regulates fluid flow through the first inlet / outlet 110 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com