Device applied to material object erosion-corrosion test of engineering pipe

A test device, erosion corrosion technology, applied in the direction of measuring device, weather resistance/light resistance/corrosion resistance, analysis materials, etc., to achieve the effect of improving operation stability, improving air tightness and operation stability, and avoiding heat accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

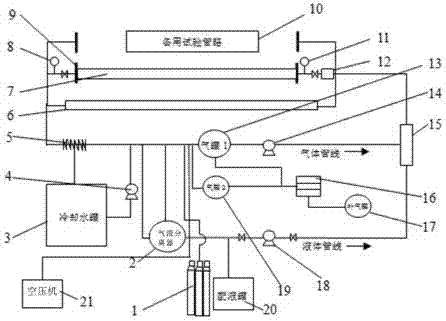

[0052] see figure 1, a kind of engineering pipe erosion corrosion test device provided by the embodiment of the present invention, engineering experimental pipeline, gas circulation module, liquid circulation module, heat dissipation module, heating module, automatic control and data acquisition module; said engineering experiment The pipelines are used to fix the engineering pipes for physical erosion and corrosion experiments; the engineering experimental pipelines are greater than or equal to one, and each of the engineering experimental pipelines can be clamped with an engineering pipe 7, and the engineering pipes 7 is connected to the connecting pipe through the flange 9.

[0053] Specifically, the engineering experimental pipeline includes a first fixing part and a second fixing part arranged in parallel, and the first fixing part includes a first end and a second end for fixing the engineering pipe material 7, respectively arranged at the first end and the flange 9 at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com