Fuel explosive performance testing system and fuel explosive performance testing method

A measurement system and measurement method technology, applied in the direction of material explosion, to achieve the effect of ensuring speed and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

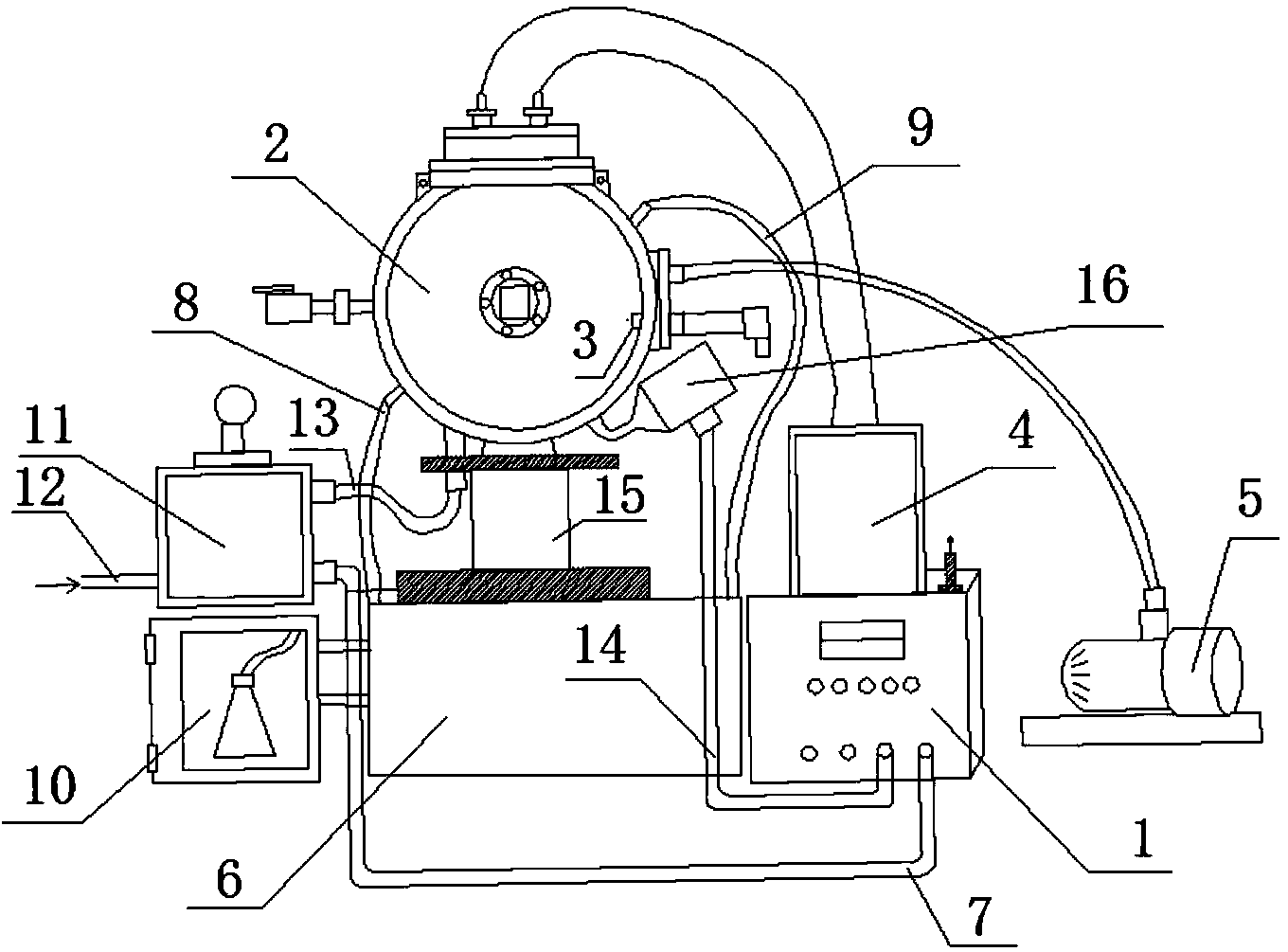

[0028] Such as figure 1 As shown, the fuel explosion performance measurement system of the present invention includes a computer, a main control system 1 and a high-pressure air supply device connected to the main control system 1, a sampling device, an explosion chamber 2, an ignition device 4 and a vacuum device 5; An information collection device 3 is fixed on the inner wall of the chamber 2; an ignition electrode is detachably installed on the top of the explosion chamber 2, and the upper part of the ignition electrode is connected with the ignition device 4; the explosion chamber 2 is connected with the sampling device and the vacuum device 5; the computer and The information collection device 3 is connected.

[0029] The above scheme has been able to complete the determination of fuel explosion performance, and the preferred scheme is given below on this basis:

[0030] Such as figure 1As shown, the fuel explosion performance measurement system also includes a constant...

Embodiment 2

[0035] A kind of method that adopts embodiment 1 fuel explosion performance measurement system to carry out the method for fuel explosion performance measurement, comprises the steps:

[0036] A. Clean the inner wall of the explosion chamber 2 and the ignition electrode; seal and fix the explosion chamber 2, insert the ignition electrode; open the thermostatic device 6, keep the temperature of the explosion chamber 2 and the liquid fuel supply device 10 at 60°C, and open the liquid fuel supply device 10. Inject 50ml of light diesel oil into the microcomputer-controlled variable particle size atomization system 11, and seal the cover; the main control system 1 inputs a constant pressure to the microcomputer-controlled variable particle size atomization system 11 through the high-pressure dry air pipeline 7 for gas sampling air, the constant pressure is greater than the internal pressure of the microcomputer-controlled variable particle size atomization system 11; run the liquid ...

Embodiment 3

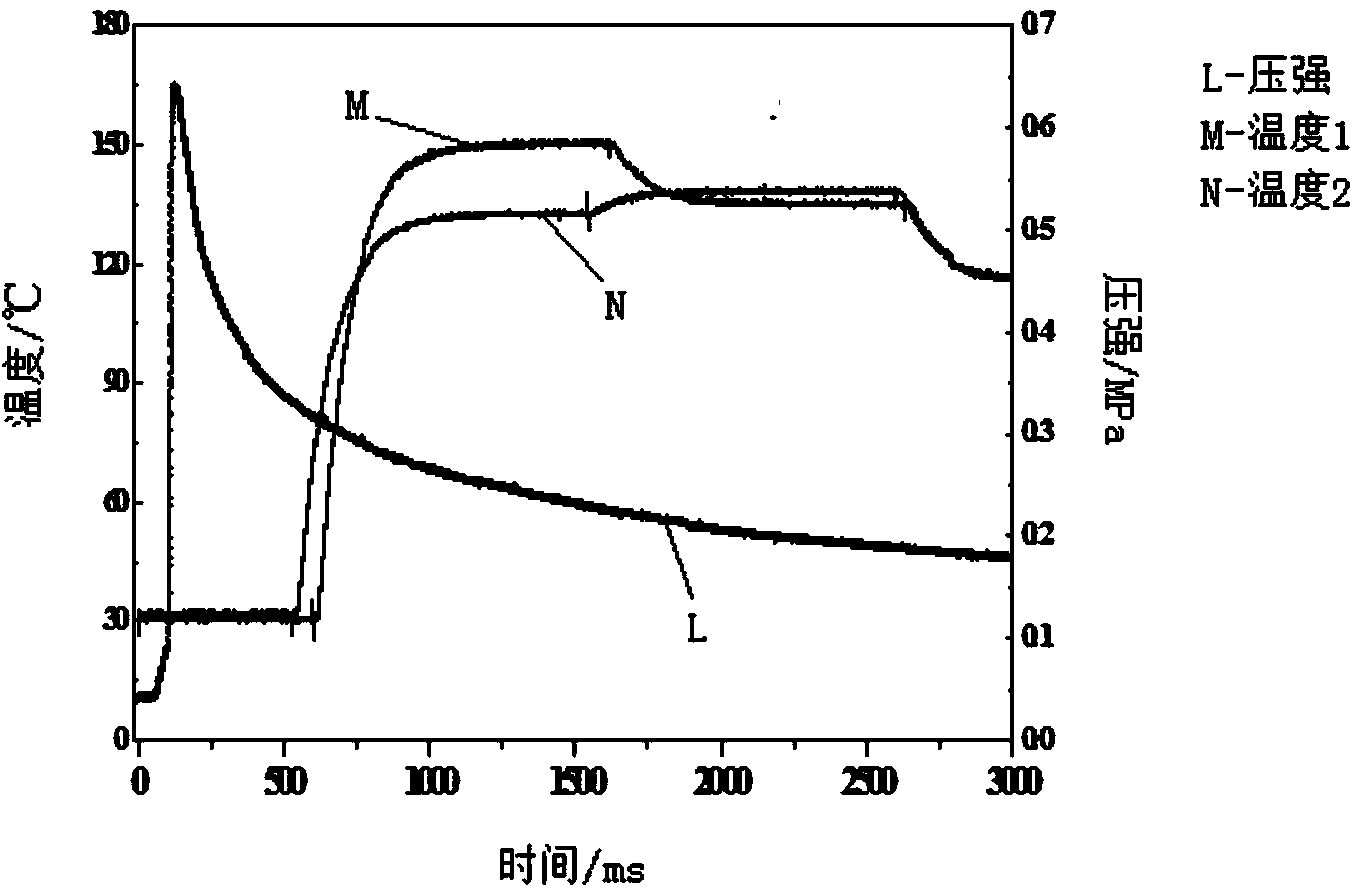

[0040] In this embodiment, the main control system parameters are set as follows: the internal pressure of the microcomputer-controlled variable particle size atomization system 11 is 2.0 Mpa, the internal vacuum degree of the explosion chamber 2 is 0, the ignition delay time is 600 ms, the ignition duration is 1000 ms, the temperature and The start time of pressure collection is 0 ms, that is, the collection starts at the moment of injection, the collection duration is 3000 ms, and the collection time interval is 10 ms; other steps are the same as in Embodiment 2.

[0041] The measurement result of this embodiment is: the explosive performance of light diesel oil is better than that of n-dodecane.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com