Shield conductor, and method of manufacturing same

A technology for shielding conductors and manufacturing methods, which is applied in cable/conductor manufacturing, conductors, and conductive connections, etc., can solve the problems of uniformizing the metal braided portion and the shielding tube, increasing the number of parts, etc., and achieves high electrical contact reliability. The effect of the number of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

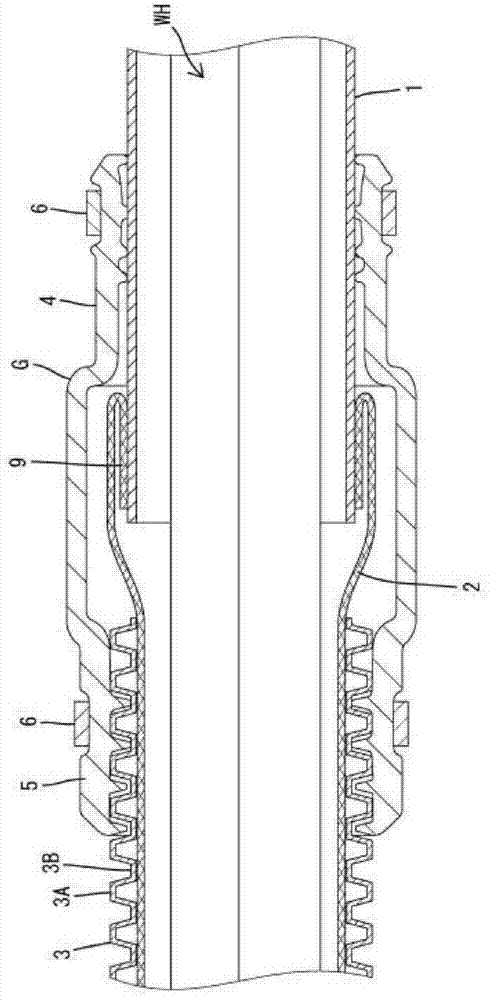

[0026] Embodiment 1 in which the shield conductor of the present invention is realized will be described with reference to the drawings. In the present embodiment, in the hybrid vehicle, the wire harness WH connecting the battery mounted in the rear compartment and the inverter mounted in the engine room is shielded and routed.

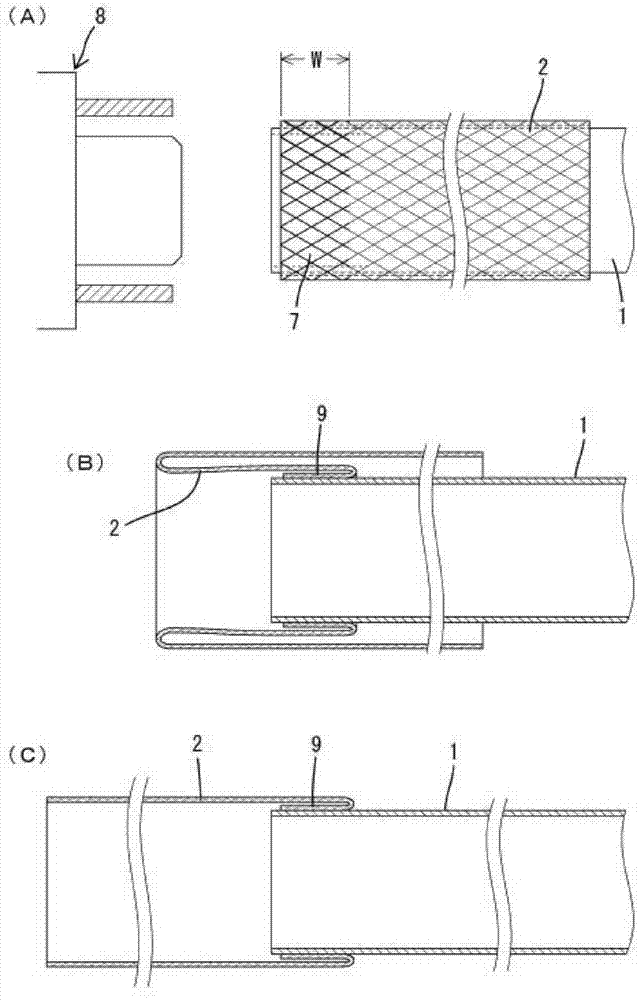

[0027] Such as figure 1 As shown, the wire harness WH is composed of a plurality of electric wires. A part of the wire harness WH is inserted into the shield tube 1 made of conductive metal. The shield pipe 1 is made of aluminum or an aluminum alloy, and is placed under the chassis of the vehicle body.

[0028] One end of the metal braid 2 is connected to one end of the shielding tube 1 . The metal braid 2 is formed, for example, by braiding copper-based metal wires with tin-plated surfaces in a mesh-like elongated cylindrical shape. The electric wire drawn out from the shielding tube 1 is inserted into this metal braided part 2 . The end of the ...

Embodiment 2

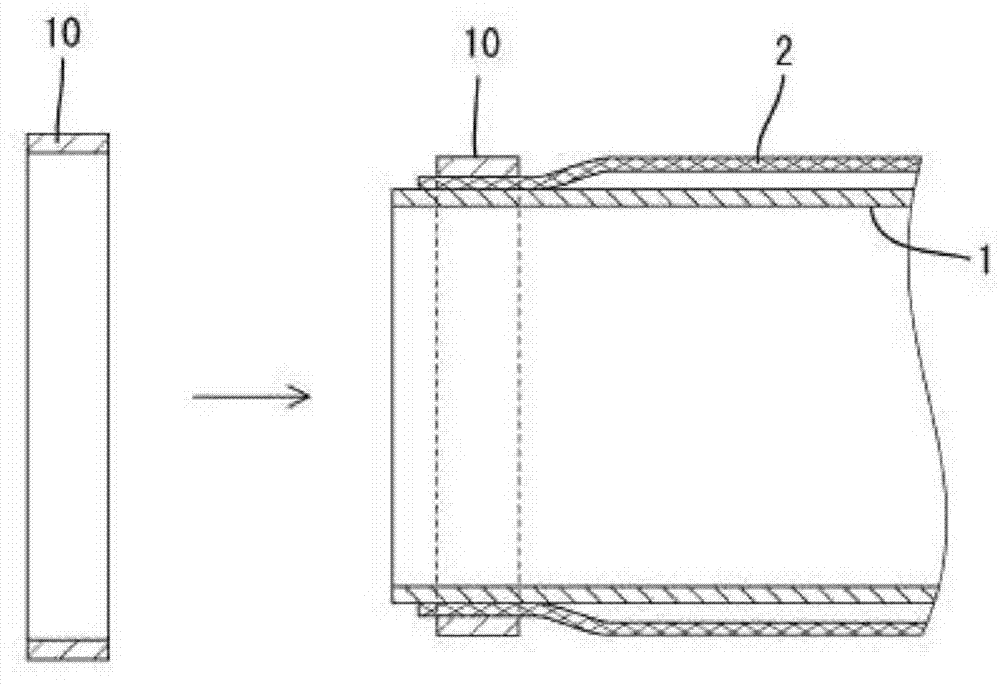

[0039] image 3 Example 2 is shown. In Embodiment 1, the metal braided part 2 and the shielding pipe 1 are directly welded, while in Embodiment 2, the metal ring 10 for welding (corresponding to the welding part for connection of the present invention) is embedded in the first embodiment before the welding operation. Up to the end of the metal braided part 2, the metal braided part 2 and the shielding tube 1 are welded by means of ultrasonic welding or the like to melt it.

[0040] The material of the metal ring 10 can be selected from materials that can be welded to the shielding tube 1 such as aluminum, aluminum alloy, copper, and copper alloy, for example. The metal ring 10 is melted by the ultrasonic welding process, and flows between the metal braid and the shielding tube through the gaps in the mesh of the metal braid. In this way, after the molten metal is solidified, the metal braided part and the shielding pipe are connected and fixed.

[0041] In addition, it is not...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com