Silver-based alloy material and application thereof

A silver-based alloy and alloy technology, applied in the direction of contact materials, can solve the problems of low hardness and wear resistance, unstable contact resistance, and low contact reliability, so as to improve arc burning resistance, hardness and Softening temperature, the effect of solving the instability of contact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention is further illustrated below with examples, but the present invention is not limited thereto.

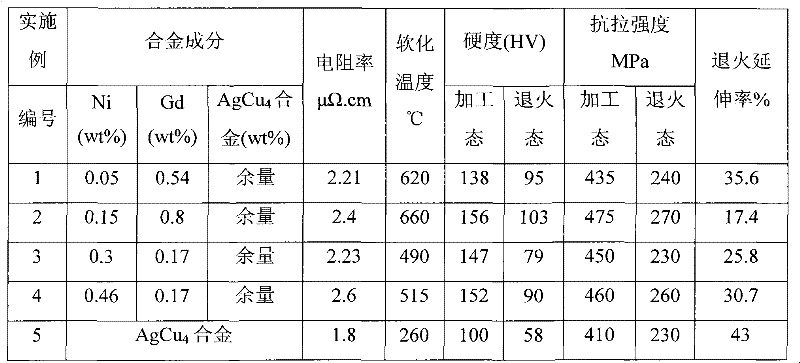

[0020] The performance data of the formula of embodiment 1~4 and the silver-based alloy material that makes, and AgCu 4 The performance data of the alloy are shown in Table 1. The purity (mass percentage) of raw materials used in each embodiment is: Ag≥99.99%, Cu≥99.99%, Ni≥99.99%, Gd≥99.96%.

[0021] Allowable impurity content (mass percentage) in the silver-based alloy material prepared in each embodiment: Fe≤0.002%, Pd≤0.002%, Sb≤0.002%, Bi≤0.002%.

[0022] Table 1 Silver-base alloy material of the present invention and performance data of AgCu4 alloy

[0023]

[0024] The preparation method of embodiment 1~4 is as follows:

[0025] By mass percentage (%): as AgCu 4 Alloy, Ni and Gd are used as raw materials, and the following procedures are carried out according to the recipes in each example: ①Vacuum argon protection smelting ②Ingot 700°C / 3h ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com