Compression-joint type IGBT packaging structure with heat tubes

A packaging structure, crimping technology, applied in electrical components, electrical solid devices, circuits, etc., can solve the problems of mechanical damage to the chip, poor thermal conductivity on the side of the chip, and inability to balance chip protection and thermal conductivity, and achieve overall thermal resistance. Small, small chip protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

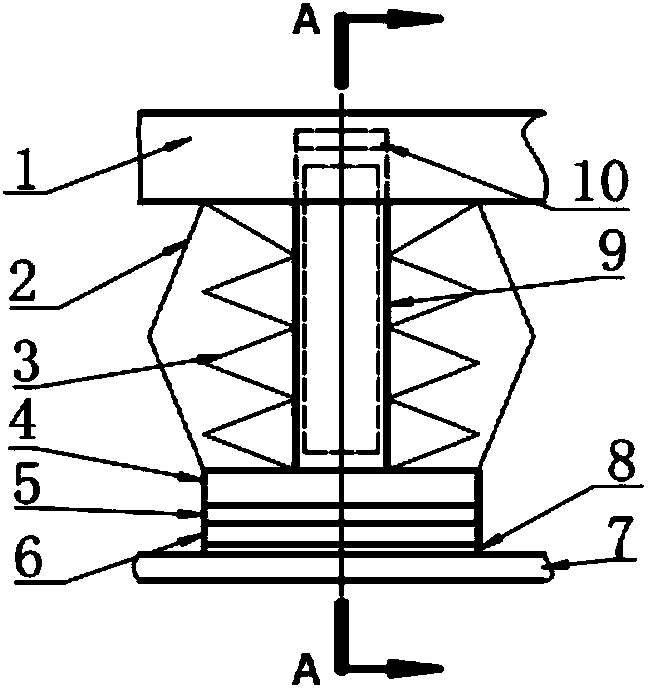

[0051] There are multiple subunits inside the device, and one subunit is a stacked structure as a whole, and there are one or more chips 8 inside it. The periphery of the subunit is protected by the tube shell. In the non-working state, the upper end surface of the subunit is slightly higher than the upper end surface of the tube shell, and the typical value is 2-3mm.

[0052] like Figure 1~5 As shown, the IGBT package structure from bottom to top is the lower end cover 7, chip 8, upper molybdenum sheet 6, silver sheet 5 (or aluminum sheet), base 4, conductive copper sheet 2 (lower end), heat pipe, disc spring group 3, Conductive copper sheet 2 (upper end), upper end cover 1.

[0053]Among them, the chip 8 can be directly crimped with the lower end cover 7, and can also be sintered with the lower end cover 7. In addition, the upper end cover 1 has a deep hole at the position corresponding to the heat pipe, and the upper end of the heat pipe is inserted into it. It is ensure...

Embodiment 2

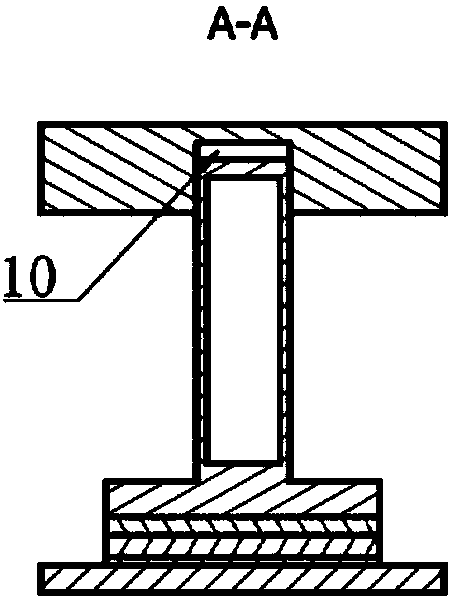

[0056] like Figure 6 and Figure 7 As shown, the lower structure is the same as that of Embodiment 1, except that a through hole is opened at the corresponding position of the upper end cover 1 and the heat pipe, and the heat pipe passes through it, and then a hole with a certain depth is opened at the corresponding position on the radiator, which is filled with high-efficiency thermal grease 10. It can ensure that there is a better heat conduction path between the heat pipe passing through the heat conduction grease 10 and the heat sink in the working state.

Embodiment 3

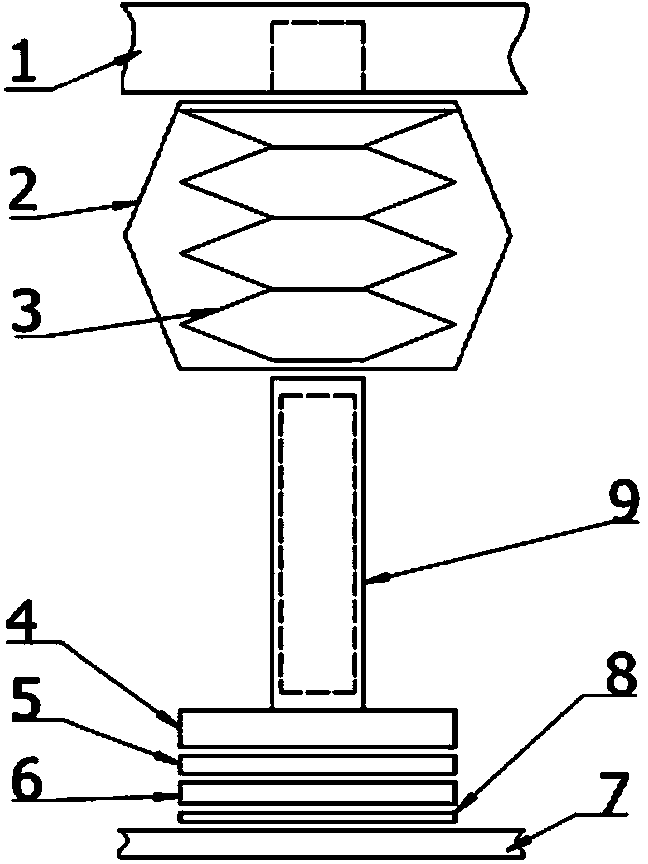

[0058] like Figure 8 and Figure 9 As shown, there are several grooves at the bottom of the base 4, in which the heat pipe can be embedded, and at the same time be compressed between the base 4 and the upper molybdenum sheet 6, so as to ensure that the heat can be better transferred from the molybdenum sheet 6 to the heat pipe, and then the heat pipe from Both sides of the base 4 are bent upward until reaching the corresponding deep holes of the upper end cover 1 , and the same deep holes are filled with high-efficiency thermal conductive grease 10 . In the figure, there are heat pipes on both sides of the base 4, or only on one side. Also similar to Embodiment 2, the upper end cover 1 may also have a through hole through which the heat pipe passes to a deep hole at a corresponding position on the radiator, and the deep hole is filled with high-efficiency thermal grease 10 . In addition, the guide rod of the base 4 can also be a heat pipe as in the first two embodiments.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com