Bridgeless electrolytic-capacitor-free low-ripple-wave high-power constant-current power supply of LED lamp

A technology of LED lights and electrolytic capacitors, which is applied in the direction of electric light source, electric light circuit layout, light source, etc., can solve the problems of lower reliability, loss of low-voltage power supply power, and working dead zone, so as to reduce THD and EMI and improve electric current. Power efficiency, the effect of improving electric power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

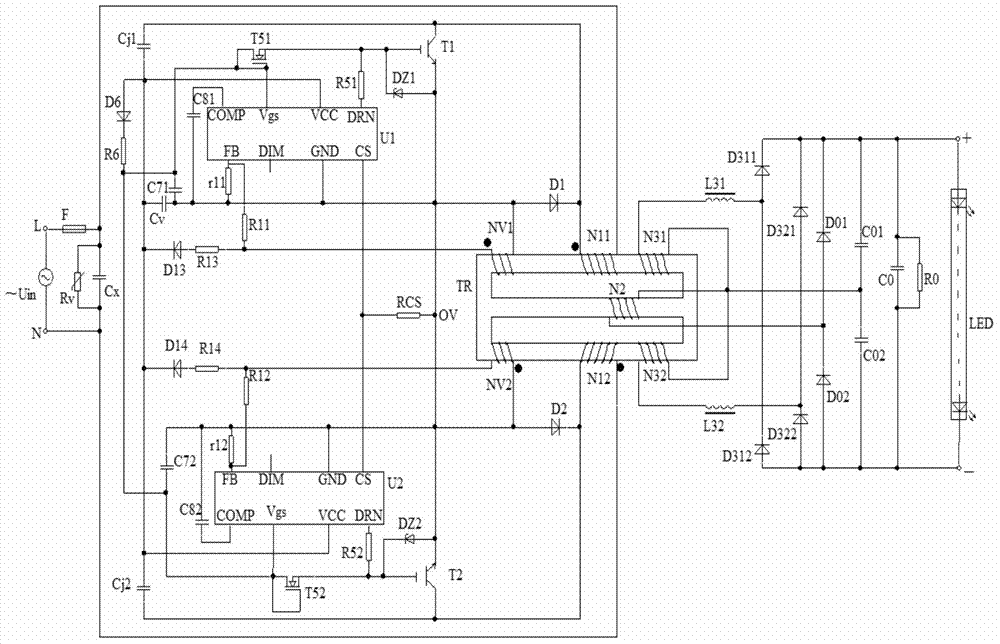

[0033] Combine below figure 1 The specific embodiment of the present invention will be further described.

[0034] Such as figure 1 As shown, there is no bridge, no electrolytic capacitor, low ripple and high power LED lamp constant current power supply, including: AC power supply circuit, control circuit, coupling output circuit and ripple suppression circuit;

[0035] The constant current power supply of the present invention adopts a magnetic integrated transformer TR, including a "day"-shaped magnetic core column, and the primary side winding N11 and the primary side winding N12 are respectively symmetrically wound on the two sides of the "day"-shaped magnetic core column On the column, the secondary winding NV1 and the secondary winding NV2 are symmetrically wound on the two side columns of the "day"-shaped magnetic core column, and the secondary winding N2 of the middle column is wound on the center of the "day"-shaped magnetic core column. On the column, the additiona...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com