Feeding device for lollipop processing

A technology of feeding device and lollipop, which is applied in the confectionery industry, confectionery, application and other directions, can solve the problems of easy fatigue, low efficiency, impact on workers' health, etc., and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in further detail below by means of specific embodiments:

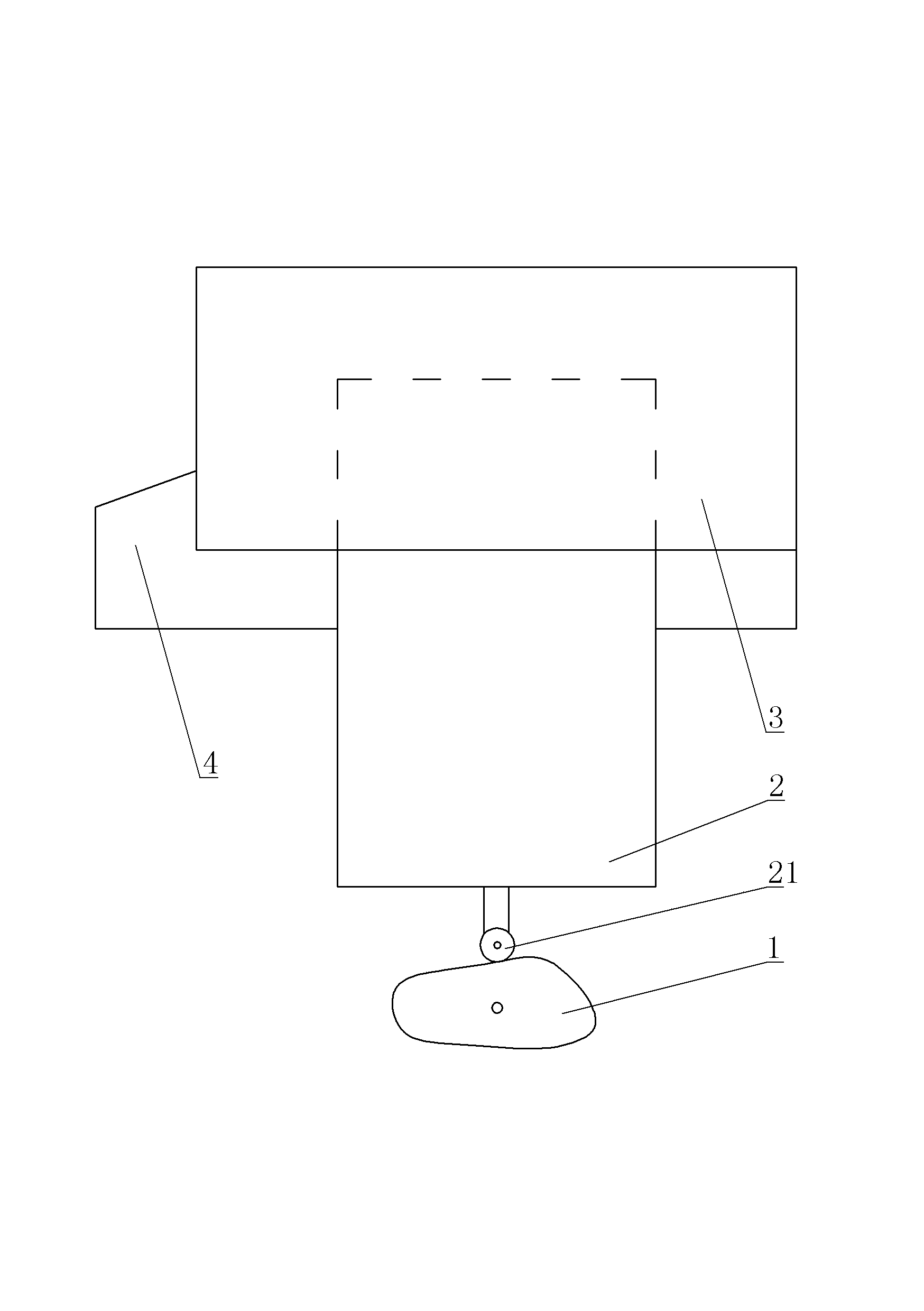

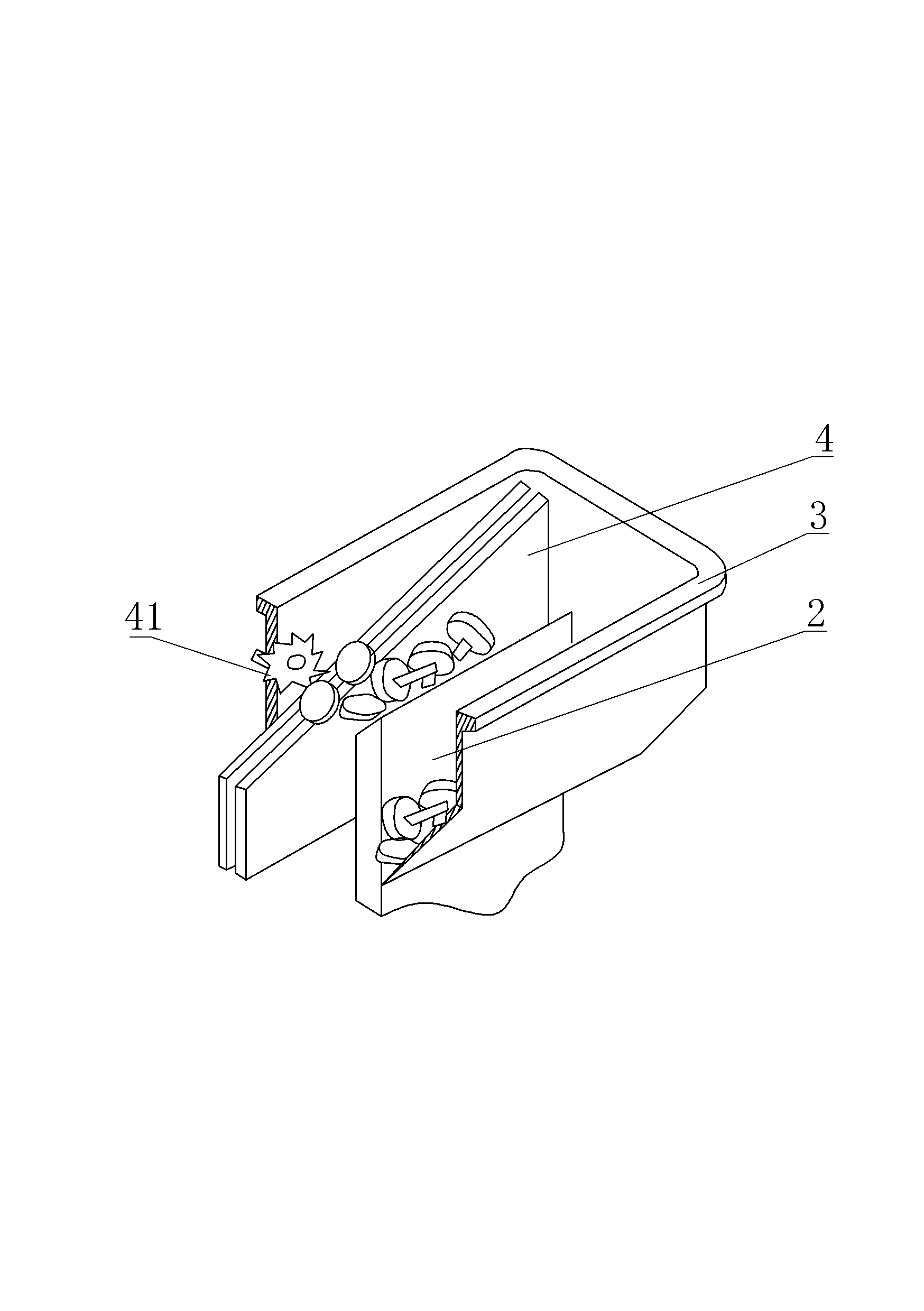

[0013] The reference signs in the drawings of the description include: cam 1 , material selection plate 2 , roller 21 , hopper 3 , discharge plate 4 , and ratchet 41 .

[0014] The embodiment is basically as figure 1 , figure 2 Shown:

[0015] The feeding device for lollipop processing includes a hopper. In the hopper, there is a vertical discharge plate that extends obliquely downward from the right end of the hopper to the outside of the hopper. The inclination angle between the discharge plate and the horizontal plane is 30 degrees to ensure that the lollipops are discharged from the material. The plate slides down to the conveyor belt at the end of the discharge plate by its own weight. The discharge plate is two pieces arranged in parallel and spaced apart. The distance between them is greater than the diameter of the lollipop rod and smaller than the size of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com